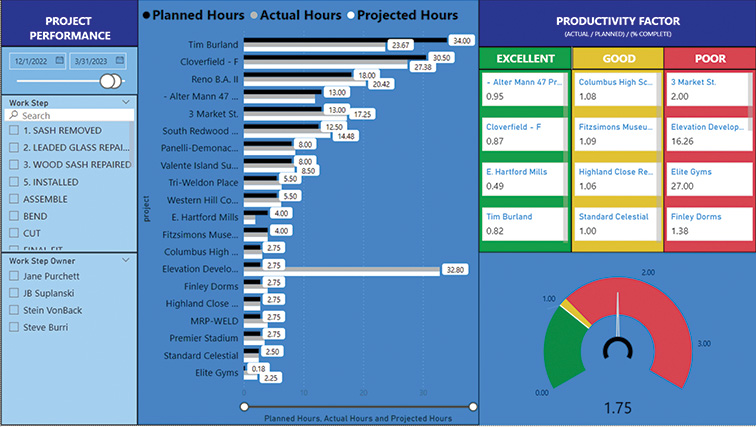

A sampling of the applications available to today’s manufacturers

The offsite construction industry has been growing. In 2021, it was valued at $49.5 billion and is projected to reach $80.8 billion million by 2031, according to Allied Market Research. In line with the growing market, the software offerings dedicated to the industry are also increasing. Below is an overview of some of the available software geared toward the offsite construction industry.

FRAMECAD

The 35-year-old Auckland, New Zealand-based FRAMECAD offers an end-to-end automated process for cold-formed steel framing. Their offering includes a design software program and an automated roll-form “printer” that makes steel framing members according to the software’s instructions.

The company claims to have the largest distribution network for cold-formed steel in the world. Customers can design from anywhere and print locally.

Customers include steel framing fabricators, design detailers and structural engineers. There are approximately 2500 software licenses and about 1000 automated steel roll-formers being used in more than 120 countries. The software will be shifting from a desktop model to a scalable SAAS model.

Photo credit: FRAMECAD

Photo credit: Frame Up Now

Photos Courtesy of Manufacton

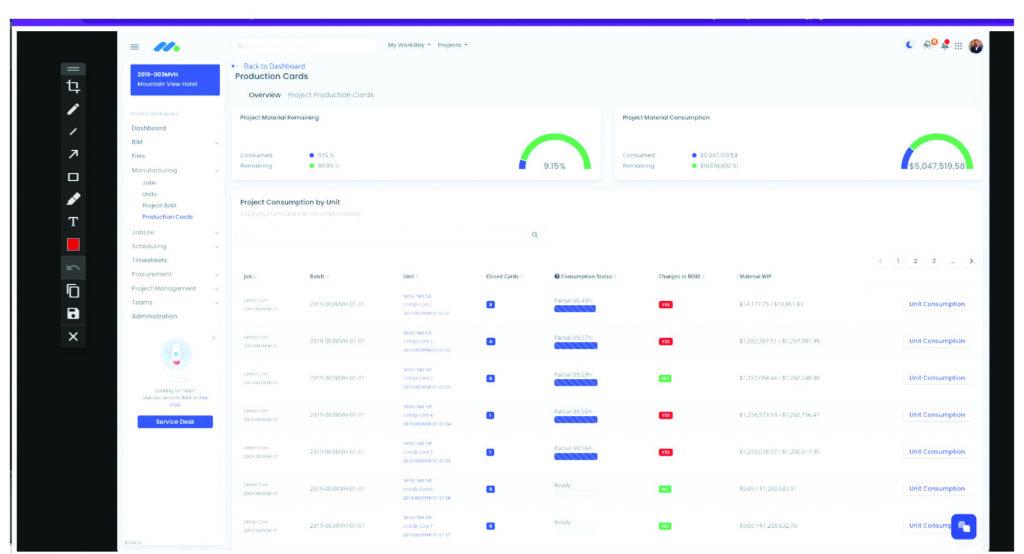

Manufacton by ViZZ Technologies

https://www.vizztechnologies.com/

This cloud-based software, which has been around since 2014, is used to manage materials, factory production and on-site installation. It puts all processes into one platform, so all departments and teams can see the real-time status of design changes, material availability, factory production and on-site installation.

Company CEO Raghi Iyengar has been a pioneer in the construction technology industry for over 35 years, leading software initiatives towards the development of the VDC (Virtual Design & Construction) process and helping bring BIM into construction.

The software improves visibility across teams and projects, with all details of the prefabrication process updated in real-time. All departments can see all aspects of a project at any time and on their preferred device (computer, phone, or tablet), making it simple for everyone to stay up to date.

Photo credit: Manufacton

The software also helps with scheduling and inventory management because work can be planned weeks, or even months, ahead.

The software integrates with: Revit and SolidWorks (design); P6 and Microsoft Project (scheduling); Accumatica, Viewpoint Spectrum, Oracle ERP Cloud (ERP); and Power BI and Tableau (analytics platforms). Integration means information need only be entered once and is available on several platforms. This eliminates extra work, reduces errors and provides status information for billing, ordering and other functions.

ViZZ is working on a new version of the Manufacton mobile app that will include a QA/QC module, time-tracking functionality and a specific views-per-job functionality. All of this is accessible via a simple QR code scan, making it easy for production teams to access work instructions and manage production from a phone or tablet.

Photo credit: Manufacton

One of the company’s customers is Oakland, Calif.-based Mighty Buildings, a 3D printing company that makes panels for residential builders and developers. They’ve been using Manufacton for approximately two years. Previously, they used a variety of software programs, but wanted to switch to an all-in-one solution. They like the fact that Manufacton’s dashboard makes tracking simple, since everything is in one place.

VP of Product Development for Mighty Buildings, Yonah Naftaly, says that Manufacton can be used in many ways and is especially helpful for companies that work out of a single location. Because the software does so many different things, however, it’s not excessively robust.

Moducore

Cloud-based Moducore was commercialized in 2019. It allows offsite manufacturers to streamline their operations, manufacturing and construction. Manufacturers can use Moducore to manage inventory in real time, to standardize and automate production processes, to track shipments from the factory to the jobsite and much more.

The software brings common ERP modules into a single, web-based platform. For instance, it generates all the data required by accounting and gives the finance team access to workstation or unit-level data. There is no longer any need to guess margins on things like individual manufactured goods and labor-to-date at workstation levels.

According to the company, the software appeals to building component manufacturers and volumetric modular manufacturers whose long-term objectives include becoming a data-first company, an objective that will help them understand where processes may be breaking down and where efficiencies may be lacking.

It is used in 129 factories and the company expects the number to rise above 200 by the end of 2023.

Moducore has also been integrating AI into its platform for the last few quarters. Moducore’s first use-case of AI was to automate customer support with a chatbot trained on its user manual. Users can now ask questions and receive accurate responses in real-time for almost any question as it relates to the software. They’re also working with select customers to train AI models based on their data to help automate everyday tasks such as bills of materials, procurement, specification summaries etc.

Recently, the company added QR functionality around components/units, as well as raw materials. Users can scan an inventory item’s QR and immediately begin interacting with that material — recording usage, creating purchase requests, performing counts, recording damage, etc.

A dedicated mobile app will be released later this year that will make it easier for individual employees to view and record things related to them alone.

Offsight

Founded in 2020 and headquartered in San Francisco, Calif., Offsight’s project management software includes a suite of products to monitor production and quality, manage factory reporting and auditing, and track material consumption and labor.

Users include building component and housing factories. Customers use the software to streamline collaboration among project managers, quality inspectors, operators, production supervisors, third-party inspectors, owners and general contractors to ensure projects stay on track.

Photo credit:: Offsight

Photo credit: Offsight

Photo credit: Offsight

Offsight says that its software is live on more than 50 factory floors around the world and experiences over 300,000 user app interactions each month.

The company offers new customers an implementation engineer who can assist with everything from account setup to on-site training/onboarding and process improvement analysis. They have also helped startup factory clients create quality manuals and quality reporting systems in partnership with 3rd party and state inspectors.

One customer is Ritz-Craft, a modular building manufacturer based in Pennsylvania that sells to builders in 22 states. The company has used Offsight since 2020 as its state-mandated quality assurance checklist.

David Kazibwe, a Project Manager with Ritz-Craft, says that Offsight helps the company track progress of the production line in real time. He adds that he would like Offsight to add the ability to annotate uploaded drawings. Kazibwe recommends that future users have Offsight’s team visit their facility so they can match the digital interface to their existing workflow.

Photo credit: ZenniHomes and CRATE Modular

Photo credit: CRATE Modular & Ritz Craft Homes

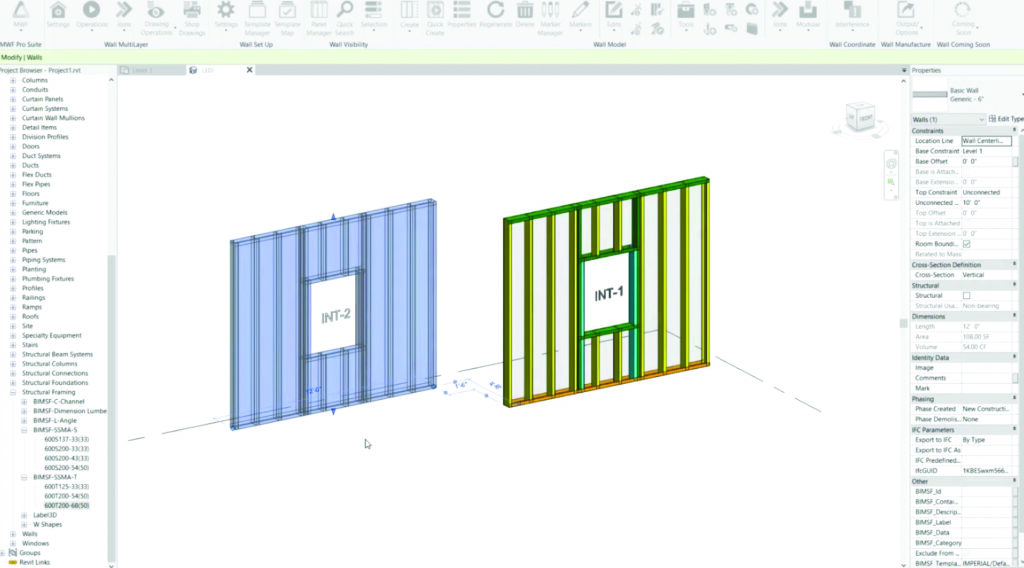

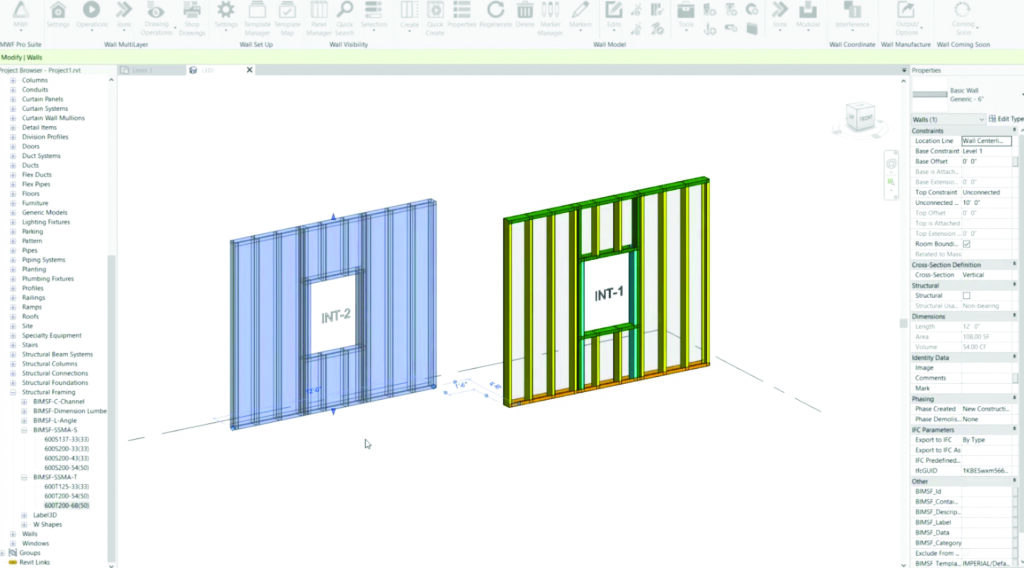

StrucSoft Solutions

https://strucsoftsolutions.com/

The company, which has been around for 30 years and is headquartered in Quebec, Canada, develops BIM framing solutions native to Autodesk Revit. The focus of their work is wood and steel framing.

Their flagship product is MWF (Metal Wood Framer), which is used by AEC customers to automate and enhance the modeling, clash detection, engineering and manufacturing of wood or light-gauge steel structures.

Photo credit: StrucSoft

Photo credit: Strucsoft

Photo credit: StrucSoft

StrucSoft is part of the Graitec Group and has many sales and technical professionals based in the UK and positioned all over the world. Their more than 10,000 worldwide users include builders, interior contractors, engineering firms, manufacturers and BIM Firms.

The company prides itself on its talented resource pool of engineers, programmers and sales executives dedicated to offering a wide range of services that include expert technical support, training, software implementation, BIM services, consultation and custom programming.

StrucSoft also has a lineup of software products that convert the designs of structural steel profiles from various CAD/CAM software into the industry standard DSTV NC1file format (a standardized file format with instructions for fabrication machinery, created by the German Steel Construction Association DSTV).

Their CMS (Component Management Software) is available either as a standalone program, or as a plug-in for Autodesk Inventor, AutoCAD, Solidworks and Metal Building Software (MBS). It integrates with industry standard machinery such as PythonX, Voortman, Prodevco and more.

FDR Engineers, a Raleigh, N.C.-based civil engineering firm with a focus on light-gauge steel panelized walls, has been using StrucSoft solutions for two and a half years. They use it with Revit to make shop drawings for manufacturer clients, and say that the software can be customized based on their clients’ preferences.