The benefits of this space-saving climate system range from aesthetics to

comfort and indoor air quality.

- The compact size of SDHV ducts makes them a good fit for most modular homes.

- The system is designed to provide better air mixing and enhanced comfort.

- The ducts and air handler can be paired with nearly any type of outdoor equipment.

Modular, system-built housing has made great strides in the last two decades. So has heating, ventilation and air conditioning (HVAC) technology, which now offers better energy efficiency, indoor air quality (IAQ) and indoor comfort. Modular manufacturers and builders have many choices when it comes to indoor climate systems.

This article will provide an overview of one such choice: the whole-house, small-duct high-velocity (SDHV) central heating and cooling system.

In full disclosure, my company has been making and selling SDHV systems in the US and abroad for nearly forty years, so my enthusiasm for the technology is necessarily biased. However, I concede that this approach is not appropriate for all housing types and I note the reasons why SDHV might not fit the bill for some modular homes.

What is SDHV?

As its name suggests, small-duct high-velocity HVAC uses ducts that are smaller than those in a traditional forced-air system.

The high-velocity part is that in order to deliver the same amount of air to a room during a given time period using smaller ducts, you have to deliver it at a greater speed. For the technically inclined, SDHV operates under high static pressure, with an average of 1.5-inches water column. It moves air at a speed of 1,000 to 2,000 feet per minute (FPM) at the 2 in. SDHV supply outlet with the airflow at each averaging between 28 to 32 CFM of conditioned air.

The system components consist of an indoor air handling unit (AHU) and the main trunk ducting, or plenum.

The AHU. The indoor air handling unit typically consists of a blower, a cooling and/or heat pump coil, or, in many parts of the country, a hot water coil for central heating. It’s a modular configuration in that each component is separate.

The modular configuration, and the fact that SDHV components take up far less space than traditional HVAC systems, eliminate the need for bulwarks, soffits, or other duct concealments. The aesthetic impact on the home is minimized and the system virtually disappears into its décor.

The system is controlled by a software-driven circuit board in the AHU that allows seamless additions such as electric heat, central humidification, connection to a hot water space heating system or domestic water heating system and high-efficiency filtration (up to hospital grade MERV 13).

The one aspect that SDHV shares with conventional systems is that return air systems can either be singular or multiple by room.

The plenum. The SDHV main supply plenum is ¼ the size of a similarly sized large-duct system, which means that 12 tons of SDHV can fit in the same physical space as a 3-ton large-duct system.

Ducts can be round, rectangular (3.5-in. high by 14.5-in. wide), or square and can be made from sheet metal or pre-formed fiberglass. In many modular homes, the 3.5-in. x 14.5-in. duct can be installed between first and second-story modules to supply up to 3.5 tons of conditioned air to both.

The fact that the SDHV flat plenum can be installed in the factory, in the interstitial space between modules, is a huge benefit.

The supply ducting has a 4-inch outside diameter and a 2-inch. diameter core. It’s designed both to deliver the air and to ensure that the air is very quiet when it enters the room. Ducts fit in the interstitial space where the plenum is located and connect to the side of the plenum via leak-free gasketed take-offs. They deliver air to 2-in. diameter supply grilles in ceilings, walls, or floors.

On-site, when the second-floor module is set on top of the first-floor module, connecting the SDHV takes a single laborer less than an hour.

You will note that I haven’t mentioned outdoor components. That’s because most SDHV systems are compatible with major brands of outdoor compressors, condensers, chillers and heat pumps (air, water, or geothermal).

End-User Advantages

In addition to the space-saving and aesthetic benefits, SDHV systems have compelling advantages over traditional HVAC systems when it comes to energy efficiency, IAQ and comfort.

Energy Efficiency. The cooling and heat pump coils in an SDHV air handling unit are twice as thick as those of a similarly sized large duct system. The increased thickness means that air stays on the coil longer, so it absorbs more heat from the outside airstream in winter and removes 30% more relative humidity in the summer.

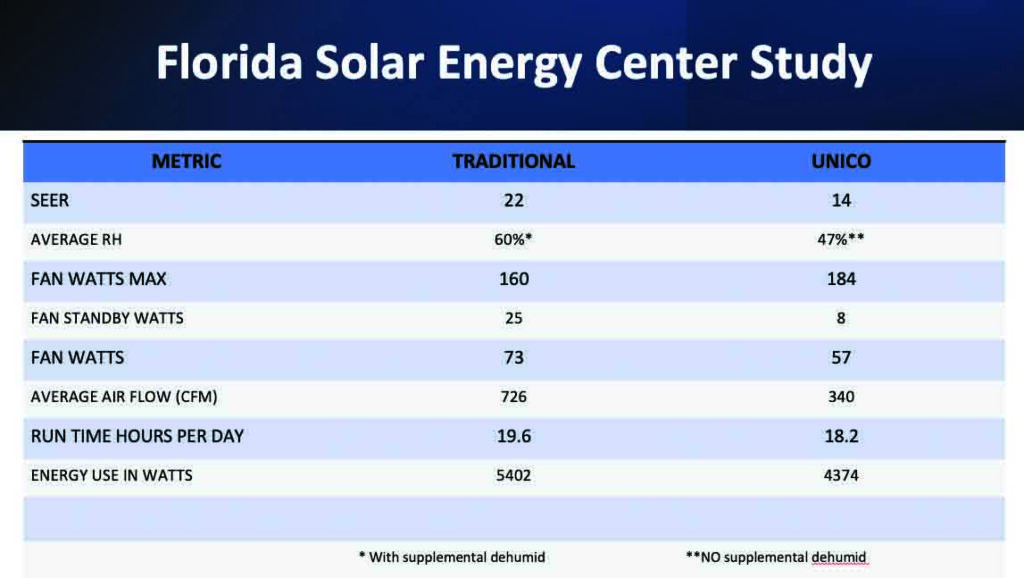

The occupants will feel more comfortable at higher thermostat settings in summer, leading to less on/ off cycling and lower energy usage.

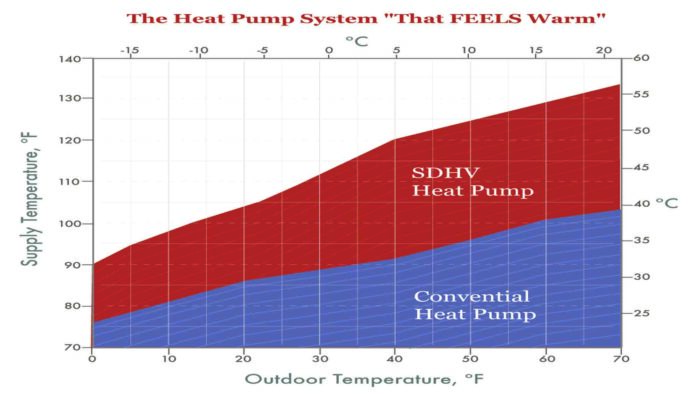

During the heating season, SDHV heat pump coils deliver a much hotter supply air than conventional heat pumps — 113 degrees F at the outlet at 30 degrees outdoor temperature, compared to 90 degrees for a traditional large-duct system.

This further lowers energy bills by reducing the need for electric resistance backup coils.

A year-long study by the Florida Solar Energy Center (a Department of Energy partner for efficiency testing) found that a 14 SEER SDHV system used 22% less energy than a large-duct 22 SEER system. The home was also more comfortable.

When properly installed, the thermal loss of an SDHV system is less than 3% of capacity. By comparison, the large-duct system with four times more surface area can have thermal losses upwards of 10% of capacity.

IAQ & Comfort. SDHV’s humidity removal lowers the risk of mold and other allergens. And because the supply and return ducting are designed to be leak free, there’s less chance for hair, dust particles, or other allergens to get into the system. SDHV systems are compatible with most major IAQ add-ons such as air filters and purifiers.

Further, instead of the dump-and-throw air delivery of conventional HVAC systems, an SDHV system uses an aspirational approach. Supply openings are placed in different parts of the room (the number and placement depend on room size and geometry), which provides better air mixing and more even temperatures from floor to ceiling, with no drafts or hot and cold spots. It also makes this system quieter than its traditional counterparts.

In The Factory

The small, modular components of an SDHV system mean that it can easily be integrated into the home’s structure at the factory.

A reputable SDHV manufacturer can provide the factory with the critical requirements for easy system integration: the appropriate heating and cooling load calculations to properly size the indoor comfort system; a system duct design including AHU placement, plenum and supply layouts; and a material list for all needed equipment.

The SDHV manufacturer should also be willing to visit the factory to perform the first installation and help the modular manufacturer create a process for quickly and properly integrating equipment for subsequent installations.

During the first module set (and maybe a few subsequent ones), the SDHV provider should also make themselves available on-site. They need to ensure that the builder’s team understands how to do the final supply duct and outlet hookups, how to install the outdoor equipment and how to commission the system to ensure that it’s operating properly.

In such a scenario, all sales and equipment logistics should be direct from the SDHV manufacturer to the modular home factory and jobsite. This eliminates markups at the distributor and contractor levels and establishes a one-to-one relationship between the two manufacturers.

Having such a relationship allows modular home sellers to offer their clientele a more complete home package that can be sold at a higher premium.

Despite the advantages of SDHV systems, they won’t always be the best solution. They command a slight premium over traditional HVAC and so may not be a good fit for a high-volume, low-cost modular company. You could say that SDHV technology, with its innovative design and superiority in delivered comfort and efficiency, is a special system meant for special homes with discerning owners

If that last sentence describes your business approach, product quality, and clientele, then SDHV HVAC may be the perfect fit for you and your business.