Virtual walkthroughs and 3D modeling are animating both the design process and marketing approach for new homes.

- Virtual walkthroughs enable prospective buyers to visualize new homes, hide furniture

and change not only finishes, but also room features. - Animation and video are useful in demonstrating to jurisdictions what a project will look

like within the context of the neighborhood. - 3D modeling minimizes change orders and worksite delays by resolving problems and

overcoming challenges during design.

Today’s digital technologies are elevating the marketing, design and construction of modular and conventional homes alike. These technologies offer real benefits to the builders and housing manufacturers who use them.

On the sales and marketing side, virtual walkthroughs put more choices in the hands of buyers. As they move around the house, they can view rooms with or without furniture and see how a living space would look with upgrades. This can speed up home sales and help buyers choose more options.

When it comes to design and production, working in 3D allows architects to resolve areas of the design that aren’t typically visible in 2D. This helps with constructability, because they can see where, for example, a roof intersection is overly complicated.

The architect can use software to create design documents and specs that, in turn, are used to produce detailed, 3D models, shared with all members of the project team. While 3D modeling isn’t new, it has progressed to the point where a high-performance, energy-efficient home can be designed down to the last fastener.

Animation and video are also helping with approvals, says architect Donald Ruthroff, AIA, Founding Principal of Design Story Spaces in Daly City, Calif. “It has changed the face of entitlements because we can demonstrate to jurisdictions what our projects will look like within the context of the surrounding existing fabric of the neighborhood,” he explains. “This extends to neighbors who, when they are truly engaged in the project, become less fearful of what we are proposing.”

Image courtesy of Anewgo

From 2D to 3D

Anewgo, based in Holly Springs, N.C., started in 2001 as Rendering House, a visualization company that created collateral materials for new-home builders across the United States. In 2020, the firm changed its name to Anewgo.

“We’ve gone from doing 2D floor plans and renderings of exteriors to 3D virtual tours that include clubhouses, aerials, streetscapes and videos,” says Anewgo President Stephen Chan. “Plus, we offer software and interactive web tools to help people find and purchase homes and choose their finishes and options.”

Most consumers are comfortable watching videos on a computer or mobile device, but may hesitate to try more cutting-edge technologies such as augmented reality or VR headsets. “We look for a sweet spot where technology can help us create products that meet the buyer’s expectations and level of tech savviness,” he says.

Anewgo uses 3D modeling, along with photos and renderings, to create a virtual tour. “It’s like a documentary, in a way,” Chan says. “You can cut corners and bypass certain scenes and hallways and show only certain rooms, such as the kitchen and master suite.”

The company adds interactive elements such as hiding or showing furniture, which helps viewers visualize the size and characteristics of the room. With another click, they can view interior design schemes with different lighting, flooring, cabinet colors and hardware finishes, or room upgrades such as a deluxe kitchen with a double wall oven.

“The room-options feature is taking virtual tours to another level,” he says. “Not too many [visualization] firms are doing it. It’s a difficult task because we have to build to spec and get it right the first time.”

Image courtesy of Anewgo

To make the tour development process as efficient as possible, Anewgo requests floor plans, cabinet designs, electrical plans and other objective information. “We ask a lot of questions, such as the type of pulls for the cabinet doors and drawers,” Chan says.

“If there is tile in the shower, is it 7 feet high? 8 feet high? Floor-to ceiling? Does the countertop have a rounded or waterfall edge?” Once this information is incorporated, clients select furnishings and décor, using photos of model homes for inspiration. “In a sense, we’re the digital subcontractor and the builder is our homeowner,” says Chan.

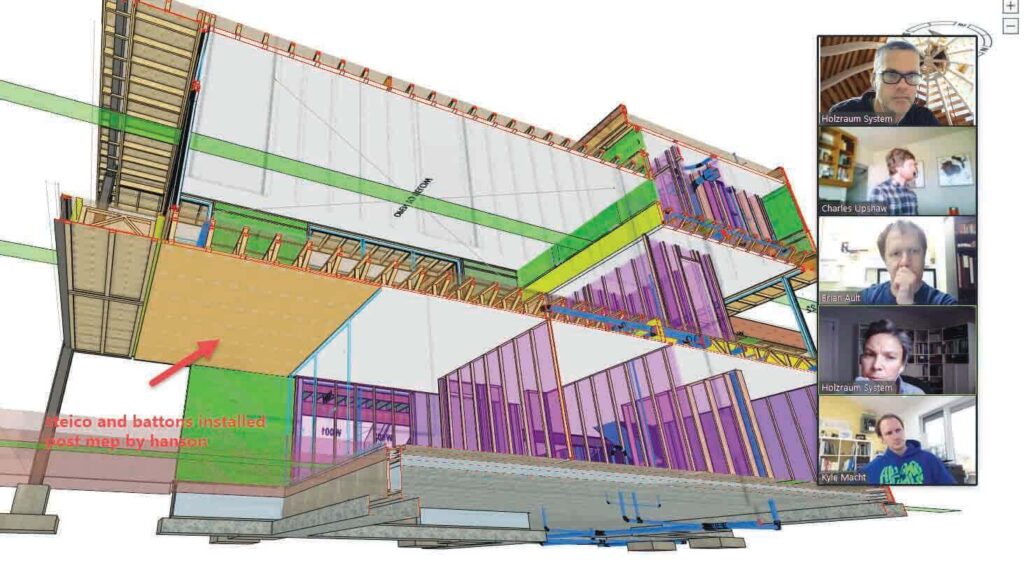

Photo credit: Courtesy of Holzraum System

Honing the Experience

Anewgo ensures that virtual tours provide the best possible experience, not just for desktop computers, but also for mobile devices. The company is always looking for ways to use interactive content to enrich the experience. “It might be information about a product or a tip about the floor plan that buyers might not expect,” Chan says. “The goal is to keep visitors on the site longer and coming back, so there is replay value.”

Laura Siegmund, a Partner at Raleigh, N.C.-based Midtown Custom Homes (Midtown), has worked with Anewgo on several virtual tours, providing floor plans, selections, paint colors, finishes and molding and trim styles at the start of the collaboration. Anewgo then creates the renderings and sends them to Midtown for edits.

In addition to the interior, Anewgo creates exterior views, enhanced with photography and drone videos, that allow buyers to walk around the house and use any entrance to go inside.

Siegmund says the biggest benefit of doing a virtual tour is being able to show the client what the finished product will look like before it is constructed: “It’s also a great reference to share with vendors as you are ordering supplies for the new home.”

Software Synchronization

Holzraum System, a Philadelphia, Pa.-based company, collaborates with architects and builders on 3D models of single-family detached homes and small commercial projects. The company specializes in high-performance housing and Passive House design for both stick-built and prefabricated homes.

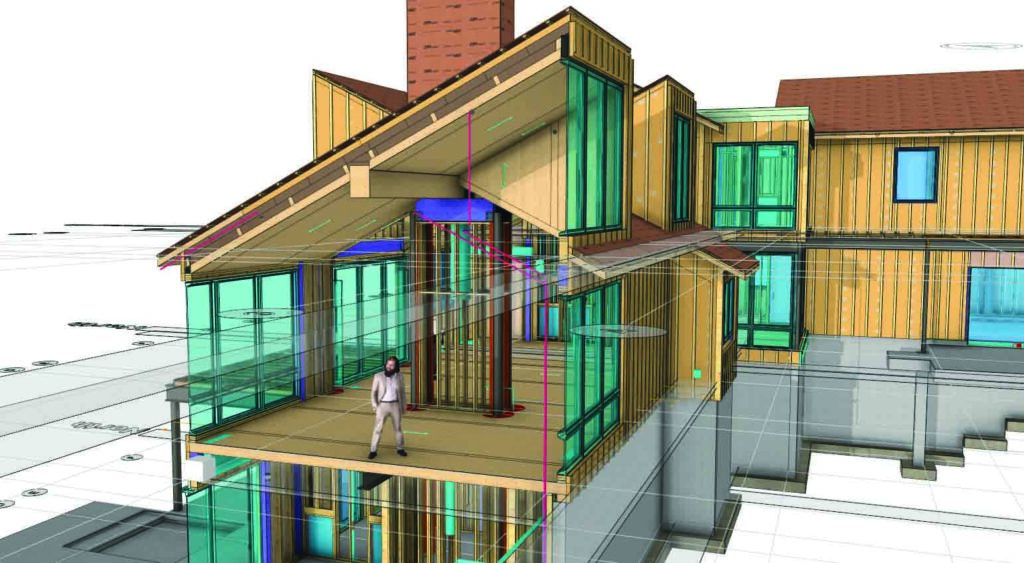

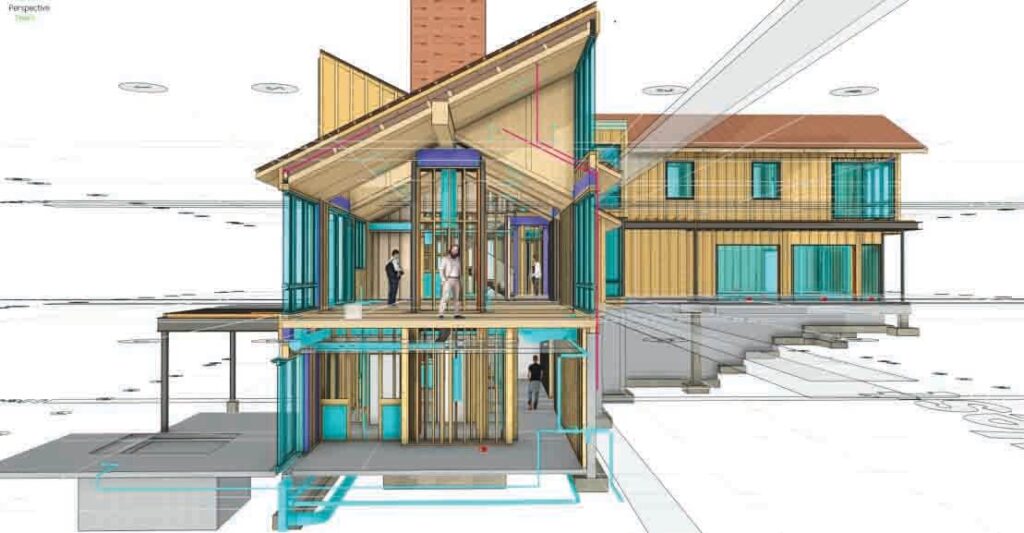

Photo credit: Courtesy of Holzraum System

For clients who wish to use off-site fabrication, Holzraum developed a program called Single Integrated Manufacturing Model (SIMM) that creates a detailed digital model in which users can zoom in on any detail, then click it to see the specs related to that part. SIMM can slice the model into layers — such as isolating foundation or wall panels — and provide views of them individually, or combined with others.

SIMM allows for better project communication, says Ilka Cassidy, Co-Founder of Holzraum, who is an architect and Certified Passive House Consultant (CPHC).

Holzraum acts as a bridge between the architect/designer, the builder and the off-site fabricator. “SIMM is different from BIM or volumetric modeling software,” Cassidy says.

“The fabricator is able to take our 3D model and integrate it into their workflow.” While most architectural firms have some level of 3D modeling capability in-house, “What’s new to all of our clients is that it’s really a manufacturing model,” explains Steve Hessler, CPHC, heavy-timber structural designer and Holzraum Co-Founder.

Risk Reduction

One Holzraum project currently under construction is a 7,500 sq. ft. custom home in Big Sky, Mont. “It’s not a passive house, but it is a high-performance panelized house with good vapor barriers and assemblies to help improve energy efficiency,” Hessler says.

Holzraum used the SIMM program to model the home. “We figure out where the panels should break and what structural members need to be in the panels,” says Hessler. “We’re able to do a super-tight clash detection [with our software]. [Clients] typically don’t have that capability.”

The company plans to take its video capabilities to the next level for both marketing and educational purposes via Blender, an opensource rendering and animation tool. “All of the textures from our parts are being fed into a Blender model,” he says.

Holzraum is also perfecting the integration of animation into short videos that it will post online. “The software will allow us to move things around, make layers dissolve and disappear and incorporate annotation,” says Hessler.

Photo credit: Courtesy of Holzraum System

The Architect’s Experience

Macht Architecture in North Kingston, R.I., recently worked with Holzraum on a SIMM process to panelize one of their designs.

“We tweaked some parameters in order to be able to panelize the project,” says Kyle Macht, CPHC and Principal. “Then we sent them to our model file, and the back and forth began.”

During the design process, Macht met with Holzraum and other team members weekly (and sometimes daily) to resolve challenges and tweak the design. “Many of our windows were floor-to-ceiling, and some were both floor-to-ceiling and wall-to-wall, meaning we had to get our tolerances really tight for everything to fit,” he says.

Macht has been doing 3D modeling for 20 years, so it isn’t new to him. “Where this differed was that Holzraum modeled every stud, every connector, every layer, etc. Quite a few adjustments had to be made that normally would result in tearing things apart on-site to get everything just right.”

Another benefit was that the team had more control over the materials and systems used for the envelope. For example, the lumber was all FSC, which is expensive and difficult to get at a local lumberyard.

Macht adds that Holzraum’s expertise in high-performance housing is a big bonus. “Typically, we are the only member of the project team, besides some of our consultants, that understands Passive House and high-performance building enclosures,” he says. “Having Holzraum already on board with those ideals, along with the builder, made the entire project run smoother. We have to convince builders and clients that investing a little extra upfront is a better long-term decision.”

Regarding virtual tours, Chan says that, in the future, buyers will demand an even greater number of choices. “People expect more content today. Builders will have to step up their use of technology while also understanding that the user’s mobile device must be the newest one. The old iPhone may be too slow.”