This free tool will help builders calculate the real financial opportunities offsite-built components offer.

- Scott Sedam of True North Consulting —Mitek insists that builders would use a lot more factory-built components if they understood the true total cost savings components offer.

- Those savings only become apparent when the builder calculates all-in costs, including time saved. To help simplify those calculations, Sedam is making a set of free spreadsheet templates available.

- He is asking for anonymous feedback from users. The feedback will be used to create industry benchmarks.

We write a lot about modular construction in this magazine because we believe it will play an important role in helping plug America’s housing gap. But it’s just one offsite method, and it continues to face stiff resistance from the majority of builders. Even those who have positive views of modular understand that it’s not the “only” solution.

“Modular alone won’t solve the housing problem,” insists veteran industry consultant Scott Sedam of TrueNorth Consulting, which was recently acquired by MiTek. Instead, he believes that the most effective way to get more homes built more quickly with the current labor pool is by using more components — assemblies built in a factory then shipped to the jobsite for installation. These include trusses, wall panels, floor and roof cassettes, pre-built stairs and the like. Almost all builders and trade contractors are familiar with these and have used them to some extent.

But while components are more mainstream than other offsite approaches, they still haven’t captured their full potential market share. The reason? Perceived higher costs. Sedam insists that this perception is usually inaccurate, and he is determined to correct it.

The problem is that most builders calculate costs in a way that blinds them to the real savings and revenue opportunities offered by factory-built components. “Builders tend to rely on bid price only when comparing components to site-built assemblies,” Sedam says. “As a result, they conclude that components won’t save them money and may even cost them more.”

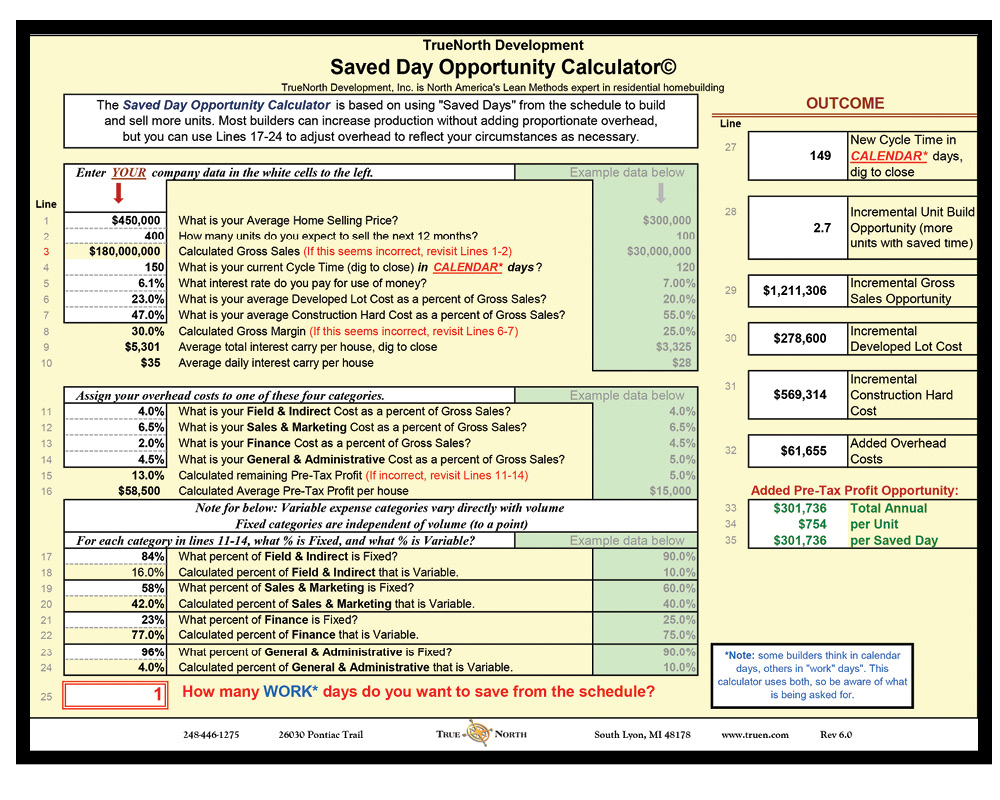

He says that the real bottom-line savings only become clear when the financial calculations take a more holistic view. The calculations need to factor in labor, overhead, interest charges, the design optimization that components make possible and the ability to complete more homes in less time without bringing on more workers. Sedam calls this the True Total Cost approach. “True total cost is all that matters,” he says.

Sedam has had success using this approach to flip previously resistant builders. For instance, he once met with a supplier in Springfield, Missouri who had been trying, unsuccessfully, for a decade to get a particular builder to switch from site-framed roofs to trusses. The answer had always been “no”, and the reason was that the supplier didn’t know how to calculate the real savings for the builder.

“The only number the supplier had ever given the builder was delivered material price, which added an extra $1800 per home,” says Sedam. After interviewing the builder, visiting one of its jobsites and examining the plans, however, he was able to calculate the total cost impact. “We showed the builder that, rather than spending $1800 more per home, the use of trusses would actually yield an additional $1800 of margin. That’s a difference of $3600.” The builder quickly made the switch.

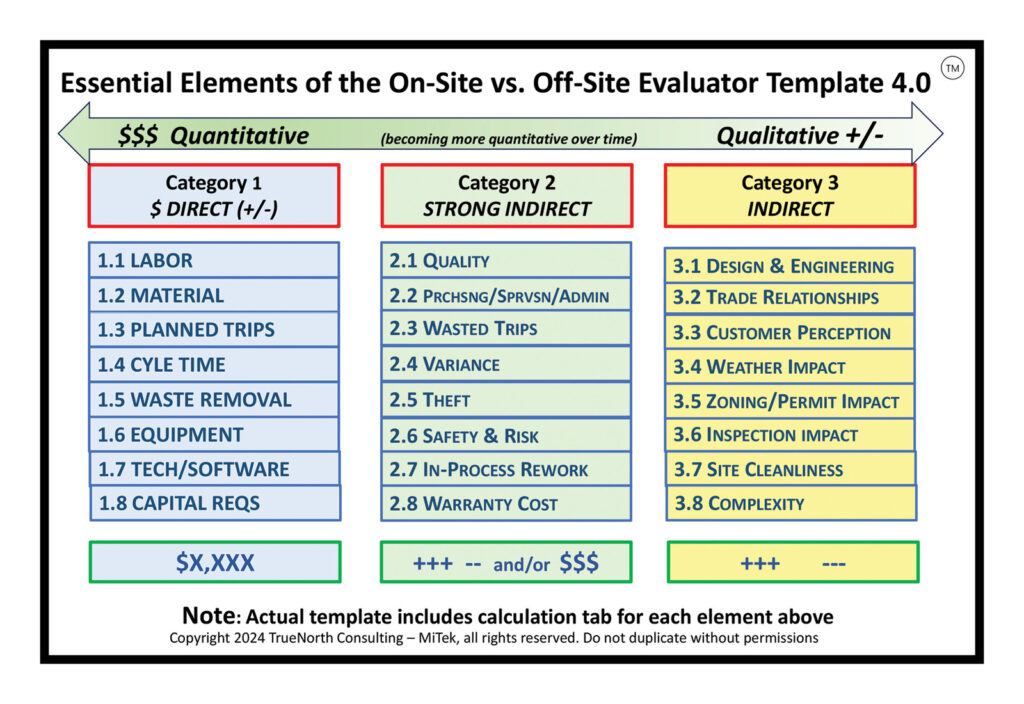

Sedam’s current goal is to help dealers and builders across the country move to using True Total Cost calculations. As part of that effort, he is offering a suite of free spreadsheet templates they can use to perform the calculations. “Builders have always lacked a comprehensive evaluation tool that measures the true total costs of site framing and components,” he says. “The spreadsheet templates provide that tool.”

Builders can use the templates to estimate the cost savings that components will likely bring in various areas. Then, as homes are completed, those numbers can be updated to show the real-world impact on the bottom line.

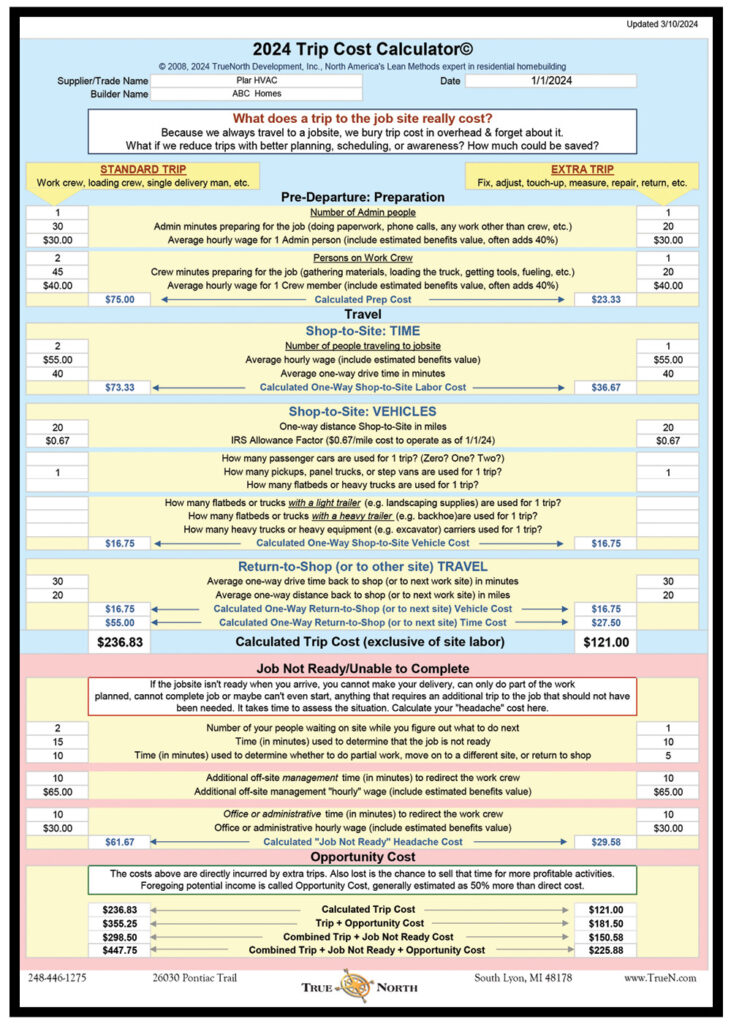

That impact usually includes, but is not limited to, labor savings from faster cycle times, fewer deliveries and/or trips to suppliers (which Sedam says currently accounts for more than $12,000 in costs per unit), reduced variances and more optimized designs.

Few builders and suppliers fully grasp the advantages of design optimization, but it can save a lot of money. For example, if you use trusses and design the home correctly, then 80-95% of the structural load will bear on the outside walls, which eliminates a lot of structural piers, posts, beams and headers. “On one builder project, this reduced the number of piers from 21 to six, at a couple of hundred bucks apiece,” he says. The spreadsheet templates will help the builder estimate and document such savings.

The calculations will also show the builder how the use of components can speed up construction time and help the company build more homes with only a minimal increase in overhead. That means more profit. “If I can build 10% more units per year and only raise fixed costs by 5%, I have increased my profit margins,” he explains.

But while Sedam is a believer in components, he realizes that they might not be the solution for every project. Use of the templates will provide the builder with data that supports good decision-making. “I’m officially agnostic about the outcome,” he says. “We want to give builders a tool they can use to make fully informed ‘go’ or ‘no go’ decisions.” However, his experience tells him that components will prove their worth in most projects.

Anyone interested in trying out the spreadsheet templates can request them by emailing Scott at [email protected].

Although the spreadsheets templates are free, Sedam is asking that users send confidential feedback on the results they get from using them. (He wants users to strip out all company information and just submit the numbers.) After gathering enough data, he and MiTek intend to put out a report that provides benchmarks that builders can use when first considering whether to use more components.

By helping more builders move towards more component use, Sedam hopes to help raise industry productivity in general. “Productivity in our industry has been declining since the 1970s because we have done a poor job of helping builders understand the financial benefits of becoming more productive,” he says. “This tool shows them the money.”

All images courtesy Scott Sedam. TrueNorth Consulting – MiTek.

Readers who want to try the spreadsheet templates can send an email request to [email protected]. He will respond with the spreadsheets, as well as with instructions on how to use them.