The author is optimistic about mass timber because it addresses some of the drawbacks of concrete and steel.

The birth of high-rises and skyscrapers in the 1880s was a defining moment in the history of architecture, engineering and construction. The International Building Code defines a high-rise as a building with a height of 75 feet or more (technically, the height from the lowest level of fire department access to the highest occupied floor). The term “skyscraper” is used pretty loosely, but generally defines a building that’s over 492 feet (150 meters) tall, with at least 50% of its height being habitable. All skyscrapers are high-rises, but not all high-rises are skyscrapers.

Built from steel-reinforced concrete, these structures grew in popularity as people migrated to urban areas. Although they were first used as office spaces, they became a popular housing option because they made it possible to squeeze more people into a given geographical area. They have come to define the skylines of many cities.

The engineering of tall buildings has always been impressive, with concrete and steel working together to hold them upright even in strong winds. But while concrete and steel are two of the most versatile and valuable building materials, they are energy intensive to produce, with big carbon footprints. They can also make interiors feel cold, harsh and uninviting.

In the search for more environmentally friendly tall buildings, designers have turned to good old-fashioned wood. Some noteworthy projects include:

• The Stadthaus in London, England. Built in 2009, it was one of the first tall buildings made of wood. It has nine stories and stands 99 feet (30 meters) tall.

• Brock Commons in Vancouver, B.C., Canada, which was built in 2017. It broke records as the tallest contemporary wood building, with 18 stories and a height of 190 feet, or 58 meters.

• Mjøstårnet in Brumunddal, Norway, which was built in 2019 and is now the tallest timber building in the world. It has 18 stories and stands 280 feet (85 meters) tall.

Designers continue to push the limits of this construction method and we’re starting to see some outlandish proposals, including a mixed-use tower in Tokyo, Japan that will contain retail, office, hotel and residential facilities. Another unconventional proposal is the Oakwood Timber Tower in London, which will have 80 stories and stand 985 feet (300 meters) tall.

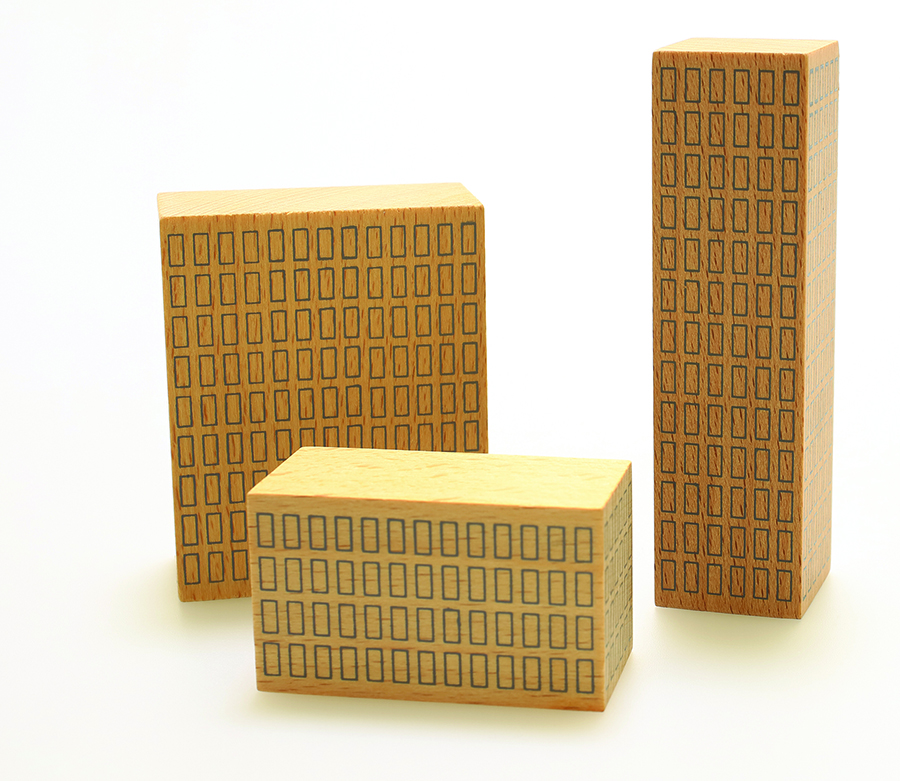

These tall wood buildings are made possible by a technology that has been growing in popularity: mass timber. Just as the mass production of steel and concrete made skyscrapers possible in the 1800’s, mass timber is what makes wood skyscrapers possible.

This technology overcomes the weaknesses of traditional lumber. For instance, wood is strong against forces parallel to the wood’s fiber growth, while at the same time being vulnerable to perpendicular forces. Wood also lacks steel’s tensile strength—the ability to withstand pulling or tensile forces—and concrete’s compressive strength—the ability to withstand compression or pushing forces.

To improve the properties of wood and make it even stronger than steel and concrete, moisture-resistant glues are used to bond layers of wood together. Examples include:

- Cross laminated timber (CLT), in which layers of wood are oriented 90 degrees to the layers next to them. (Thick CLT panels tend to be used for roof and floor assemblies.)

- Glulam, or glued laminated timber, in which thick layers of wood are glued up with the grain running in one direction. (Massive glulams are often used as beams and columns.)

One question that’s often asked is whether wood high-rises and wood skyscrapers are better than those made from steel and concrete, and in what ways? Some people believe these buildings will transform the construction industry and help save the planet. If you’ve been reading my columns, or watching my YouTube videos, you can probably guess my response. I wish I had a dollar for every time I’ve been told that a new product or technology is the LEGO of construction.

Still, I believe that mass timber construction has strong prospects for growth. Let’s take a look at its advantages and disadvantages.

Mass timber structural members like floor slabs and columns can be cheaper than steel and concrete, particularly in volatile markets like we’re experiencing right now. The lower weight of mass timber also reduces the cost of other structural members and foundations. For example, a mass timber project called The Ascent, in Milwaukee, Wis., only needed 100 support piles driven into the soil, rather than the 200 that would have been required for a similar concrete and steel building.

Even though we’re in the early stages of mass timber construction, structural engineers say that these buildings can be built approximately 25% faster than similar concrete and steel projects, with the Ascent tower being finished four months earlier than expected. However, I’m not 100% sold on the speed advantage because timetables are so project-specific—prefabricated modular steel and concrete skyscrapers can be constructed in a matter of days.

How about sustainability? The answer is that sustainably-harvested wood can be more environmentally friendly than concrete or steel. Mass timber manufacturing produces much less carbon than those materials and can even be carbon neutral or carbon negative.

That’s because, during photosynthesis, plants and trees take in carbon dioxide and give out oxygen. That carbon is locked into the tree as long as it doesn’t rot or burn. Wood for Good, a campaign by the timber industry, claims that producing a ton of bricks requires four times the amount of energy as a ton of softwood, while concrete requires five times more, steel 24 times more and aluminum 126 times more.

It’s important to note that trees used to make mass timber are selectively cut rather than clear-cut. Many companies also plant new saplings for every tree they cut down, which means that mass timber construction need not equate to deforestation.

Another surprising advantage of mass timber is its superior fire resistance compared to steel. A thick wood member will char on the outside, sealing the interior and protecting it from damage. Charred wood can also retain 85% to 90% of its structural integrity.

Of course, mass timber isn’t a miracle material. It has disadvantages that prevent its wide adoption. Concrete and steel are better able to withstand acids, alkalis and other corrosive substances. Foundations, structural cores and piers are still usually made of concrete. This sort of mass timber hybrid construction isn’t a bad thing. By merging these materials, we can get the best of both worlds—structural stability and a lower carbon footprint. The decks on the upper floors of the Mjørstårnet are made of concrete to stabilize the building and keep it from swaying.

Restrictive code requirements are another disadvantage. Mass timber structures can now be built up to 270 feet tall, or 18 stories. Unfortunately, the International Building Code requires that the timber members in many mass timber buildings be concealed because of fire safety concerns.

There’s also a significant psychological barrier to overcome. Investors may see mass timber high-rises as a risky investment. The general public might imagine that they are prone to fires and susceptible to earthquake damage. Finally, we cannot be sure that the trees used for mass timber are always sustainably harvested, especially in countries that have relatively lax restrictions on tree cutting.

In conclusion, I am excited about mass timber and hybrid timber explorations. Of course, the material itself will not make high-rises and skyscrapers magically energy efficient and it will not be the LEGO of building, whatever the heck that means. We also need good design and planning to prevent mass timber structures from being energy guzzlers. However, I believe we are witnessing the early stages of what will become a common approach to building. Mass timber will continue to improve, making it possible to push the limits of wood construction.