A sampling of the products and services you will see at this year’s BCMC Show

The annual Building Component Manufacturers Conference (BCMC) is the place for structural building component manufacturers to learn about the latest ideas, trends and products. This year’s event will be held September 12-16th at the Greater Columbus Convention Center in Columbus, Ohio, and will include a dynamic exhibit floor with machinery demonstrations, educational opportunities and new products.

The following is just a small sampling of what’s on display but should provide a taste of what you can expect to see.

The Terminailer XP Sub-Component Assembler will drive 30% to 70% of the framing nails in any wall panel, reducing the need for labor and the chance of injury. It holds six coils of 2,500 generic, wire-collated nails per coil and will nail up to six plies wide. It even straightens crooked lumber. It only requires one operator and there’s no complicated training, software or set up time. terminailer.com

Safety Speed’s VCG-515 Gypsum Sheathing Cutter uses standard utility knife blades in a cartridge-based, non-motorized system. It features a 15 ft. extended frame, is capable of 64 in. vertical (crosscuts) and unlimited horizontal (rip) lengths and can quickly change from vertical to horizontal cuts. It includes eight Quick Stop Gauges (four per side, left and right of center), a vertical end-panel snap-line edge, an integrated linear guide with a counterweight system, heavy-duty aluminum material rollers and a midway fence for narrow pieces. safetyspeed.com

SPAX’S PowerLags include a large selection of code-recognized structural wood-to-wood screws for framing. Thanks to a patented thread technology, they require no pre-drilling and drive faster and easier than conventional lags and other structural screws. The integral washer head eliminates the need for a separate washer.

PowerLags require an average of 50% fewer fasteners for ledger board applications compared to competing structural fasteners and are sold in job-friendly package quantities, including bulk pails. spax.us/setsthebar

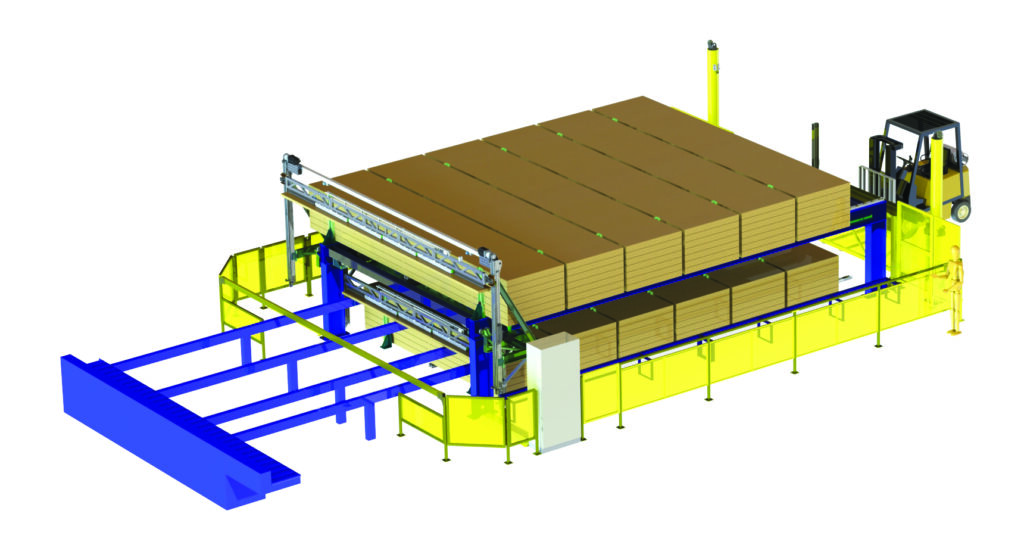

The biggest source of downtime for an automated saw is a manual infeed system that can’t keep up. Vekta’s Automated PackFeeder addresses this issue, making it a viable option for both new and existing plants.

Packs of timber are loaded onto lightweight racks. A vacuum head gantry then scans the location of each rack to profile the timber pieces. When called for by the saw, a timber of the correct length and grade is picked up with the vacuum head and delivered. The PackFeeder can deliver two boards every 15 seconds, which is fast enough to feed more than one saw.

It’s also compact. The PackFeeder’s footprint is 75% smaller than competing systems. It’s sold as a custom solution and is fully customized to your factory’s size, timber usage and processes. It can also be combined with Vekta’s Stak-n-Gap, which automatically flips boards for bow and stacks them accordingly. vektausa.com

Essetre’s Techno Saw Linear Saw is a cutting-edge technology in the processing of components for floor trusses, roof trusses and panelized building systems. It’s a compact (20ft. long) CNC working center for drilling, milling/routing and sawing of components, EWP I-Joist and timbers. The unique feeding clamp system stabilizes the workpiece during processing, while an optional unloading clamp system can be added. An 8-position rotary tool magazine is also optional.

Bar code label or inkjet printing heads can be added for workpiece identification after processing. User-friendly CAM software is included to communicate with the end user’s CAD design software. www.essetre.com

Essetre’s Techno Multiwall XS is a flexible CNC working center for drilling, milling/routing and sawing of pre-sheathed wall and/or CLT and Glulam panels. It’s unique moving machining center processes a pre-positioned panel of up to 44ft. x 10ft.. Traditional wall panels can be 12in. thick and CLT or Glulam panels up to 5 in. thick. An optional clamping system stabilizes the panel during processing and an optional nailing system can be installed to help secure sheathing panels. Other standard features include an 8-position linear tool magazine and CAM software to communicate with the end user’s CAD design software.

As is true with the company’s Techno Saw, the Techno Multiwall XS can be outfitted with bar code label or inkjet printing heads. www.essetre.com

The Squote truss application from Advanced Component Solutions makes it possible to estimate a roof truss job in minutes instead of hours. It helps designers complete more quotes, allowing them to spend more time getting orders ready for production. It’s easy to learn and uses your specific plant’s lumber, plate and associated costing factors. The company will soon be releasing Squofe, a floor truss application that offers the same benefits. advancedcomponentsolutions.net

Design needs are as variable as any other part of the business, with ebbs and flows that can make it challenging to staff accordingly. Surges in volume create times when existing staff just can’t keep up with demand. In fact, a large commercial job can tie up your best designers for weeks or months.

That’s the value of outsourcing. Component Runner, LLC is an outsource design firm exclusively for MiTek customers. They’re authorized by MiTek to provide floor and roof truss modeling and design services exclusively for MiTek component manufacturers. Their team uses MiTek SAPPHIRE for designing truss and wall panels and has completed over 10,000 jobs for more than 250 customers. The team’s Project Managers have over 280 years of experience in component design. componentrunner.com