Autodesk Revit is the big name in the Building Information Modeling world, but how useful is it? Architects and manufacturers weigh in.

• Revit has proven its value as an architectural design and project collaboration tool

• As a rule, however, BIM models created in Revit can’t handle the level of detail required by an offsite manufacturer

• Some users complain that the plugins needed to make the software fabrication-ready make it too complex

• Although other software programs may be more suited to offsite fabricators, finding people who know how to use them is difficult

• At the same time, some fabricators love Revit and have found ways to make it work for them

This article outlines the pros and cons of the most popular BIM software: Revit by Autodesk. To get a sense of its strengths and weakness, we spoke with architects, off-site manufacturers and Autodesk.

First, however, we need to define BIM, along with its best use for off-site manufacturers.

What is BIM?

Building Information Modeling (BIM) goes beyond the visualization offered by standard Computer-Aided Design. A BIM model may include information about how components are to be manufactured, costs, construction schedule, sustainability data and so on.

BIM models are classified by their level of detail (LOD). There are five levels, from conceptual design at LOD 100 to an accurate, detailed model of the as-built structure at LOD 500. An off-site fabricator will require a LOD 400 model.

How is BIM best used in off-site manufacturing?

Julian Bowron holds management positions in three Ontario-based offsite companies: Chief Technology Officer at Metaloq, which licenses cold-formed steel framing kits that ship on pallets from steel fabricators to modular builders, allowing them to quickly assemble steel frames; Chief Technology Officer at Catalyst Offsite, a company that designs, fabricates and licenses various products for off-site construction; and “Inventor-in-Residence” at Feature Walters, which designs, manufactures and installs prefabricated elements like staircases.

Bowron says that the ideal process for modular construction doesn’t start with architectural design. Instead, he advises manufacturers to first decide what materials and components (HVAC systems, door assemblies, etc.) they will use, then figure out our details such as how the drywall and the vapor barrier are attached to the studs and with which size screws. The manufacturer should use this information to design their standard module.

Only at this point should the manufacturer ask an architect to design an entire building using that standard module as a basic building block.

Of course, things are seldom ideal, and the manufacturer often has to start with the architect’s model. The fabricator needs to be able to add detail or to change the model, as necessary. At the end of the design process, there should be a complete, detailed, accurate model of exactly what will be built — down to the level of screws, bolts and welds. In this ideal scenario, “the architect’s model is a foundation for a fabrication model.”

How helpful are Revit models for off-site construction?

When an architect creates a model in Revit, building owners, permitting officials, off-site builders, fabricators and so on, can view the model without Autodesk software. In fact, it’s typical in North America for models to be viewed in PDFs or even on paper.

To change the architect’s model in any way, however, the builder or fabricator would need Revit. But Revit by itself often isn’t enough.

Sean Burke, AIA, is a Senior Architect and Design Technology Lead at GGLO Design in Seattle. He’s presented at Autodesk University and other conferences about BIM, computational design and sustainability. He’s also been a Technical Consultant for Autodesk, responsible for training, implementation and adoption of BIM processes and tools.

Burke says that “in and of itself, Revit is not a fabrication-ready tool; it’s a design and communication tool.” He says that additional software is needed to convert Revit model data into files that fabricators can use. To create models that steel fabricators can use more directly to bend and cut steel, the design teams he has been part of have used plug-ins like Grasshopper and Dynamo and have also written their own code.

Autodesk’s Inventor software can also be used for this purpose, but it’s less than ideal, according to Bowron “It’s a capable design platform, but it’s not as user-friendly as SolidWorks,” he says. He also says that Inventor isn’t fully compatible with Revit because the two programs were originally developed by different companies. (Inventor was developed by Autodesk and Revit by Charles River Software.)

“Having to use add-ons makes Revit difficult to use,” Bowron says. “Users go to hackathons and hang out with other Revit users so they can figure out their way around it.”

Even worse than Revit’s complexity is that its models are designed at “dead ends,” according to Bowron. “In almost every case, the fabricator immediately drops the [architect’s] model in the figurative wastebasket and starts from scratch and models again. The Revit model is just not useful for manufacturing,” he says.

The modeling software used by manufacturers varies. Steel frame manufacturers would likely use TEKLA, while a producer of volumetric modules might want the expanded capabilities of SolidWorks or ArchiCAD. “The most advanced go with a package with full ERP [Enterprise Resource Planning] and automation planning integration, like CATIA,” says Bowron.

When a building is designed in Revit, Bowron says it’s difficult or impossible to get the model to the level of detail and accuracy needed for manufacturing. By contrast, “an architect’s model in SolidWorks or ArchiCAD is a midpoint in a linear design process. The model serves as a foundation to add more detail, eventually becoming a fabrication model.”

Burke has a more positive view of Revit having used it, and having helped other firms use it, for more than 15 years. He has worked with many different software programs and says Revit is still his preferred architectural design tool. “It’s the best platform I’ve worked with.”

He does concede that Revit’s strength is as an architect’s tool for conveying design ideas and that additional software will likely be needed for fabrication.

Architects’ Letter to Autodesk

Bowron is not the only one who has reservations about Revit.

In 2020, over 100 architecture firms signed an open letter to Autodesk, complaining about the apparent lack of ongoing development of Revit software, despite rising costs. A similar open letter was written in 2014, by architects in New Zealand and Australia.

Tim Waldock was a signer of the 2014 letter. He’s worked as an architect, CAD Manager and BIM Manager, often working closely with software developers on ways to improve the user experience with various types of architectural software. He is also a Revit consultant who has presented at over 20 international Revit/BIM conferences.

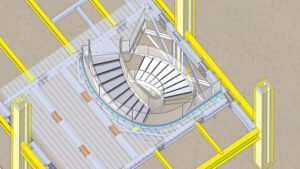

He says that although enhancements made to Revit in 2022 were welcome, “many underlying core problems were not addressed.” Outstanding issues include stairs and handrails.

“There are many problems, but the most glaring is that you can’t control the spacing of balusters on railings,” unless you happen to want the few system defaults that Revit offers, which have one or two balusters per tread. “The chances of getting what you want from Revit are less than 1%, so most people either don’t attempt to model baluster spacing or use some hideous workaround.”

Bowron puts it more bluntly: “Revit stairs are a joke.” He’s reviewed Revit models for billion-dollar projects from top 10 architecture firms and says that their models are just as bad as everyone else’s. “Everybody has problems with this software.”

In Bowron’s view, stairs are just one example of how Revit isn’t manufacturing-ready. “It’s missing all kinds of functionality, and it can’t reach the level of detail necessary for manufacturing,” Bowron says.

In contrast, “a SolidWorks model of a project shows every component as a distinct body with all clearances and tolerances included in the dimensioning. They can generate cut files for the components,” Bowron explains. “This means two things: One, the model represents a buildable reality. Two, analysis of the model is meaningful.”

Burke’s take on the 2020 letter is that software updates do provide value, even if Autodesk hasn’t yet addressed all the issues raised in the letter. In particular, he mentioned the importance of cloud collaboration.

Collaboration is a key benefit of BIM — it gives all stakeholders on a project access to the same up-to-date digital model. “Revit’s enhanced cloud collaboration was critical while working from home during the pandemic,” Burke says. “So I appreciate where Autodesk is making strategic investments and improvements.”

Autodesk’s Response

When we asked Autodesk about the complaints regarding stairs raised by Bowron, Waldock and others, they acknowledged that there was room for improvement. “Revit, out of the box, can do most stairs that are built on most days,” says David Smolker, AEC Product Marketer at Autodesk. But he admitted that “it’s not a fully complete feature set.”

Smolker emphasized that, because of the difficulties some people have had with designing stairs in Revit, lots of educational resources are available to help — Autodesk tutorials and forums, as well as materials produced by independent users. (Non-Autodesk resources he mentioned include RevitPure, the Balkan Architect, Paul Aubin, and The Revit Kid.)

For manufacturing purposes, Smolker says that Inventor is getting better when it comes to interoperability with Revit. An update in Inventor 2023 promises “an improved approach for seamless BIM and MCAD (mechanical CAD) interoperability.” An update to Revit in 2023 will include a new “cloud-based architecture-to-fabrication workflow between Revit and Inventor.”

Autodesk invites feedback on how its products can be improved. They say that the 2023 update will incorporate over 30 feature requests submitted by customers to Autodesk’s Revit Ideas forum.

Some off-site fabricators like Revit

Smolker mentioned a couple of companies that are successfully using Revit for manufacturing. For instance, Bessemer, Alabama-based BLOX prefabricates components for medical facilities such as headwalls, exam rooms, surgery ceilings and MEP racks. Southland Industries, an engineering, design and construction company with locations across the US, uses Revit to prefabricate mechanical and plumbing systems.

Judd Fuoto, Construction Technologies Manager at Southland, says that although they occasionally use Inventor and SolidWorks, they aim to be “a 100% Revit fabrication shop.” They’re getting close.

When Southland receives a design in Revit from an architect, they don’t typically try to add the detail necessary for fabrication into that same model. “When, for some reason, it’s required to have everything in a single model, it can be difficult to put in that detail without messing up what the architect or engineer already did,” Fuoto says.

Instead, the company creates a new model that they use alongside the architect’s model. The second Revit model is based on detailed component designs that Southland has already created and has in its fabrication database.

The fabrication database consists of files that represent the geometrical dimensions and other data associated with a specific MEP component that Southland manufactures. Fuoto says that creating the database was “a heavy lift” and that many companies wouldn’t have the expertise or capacity to do this themselves.

What’s an off-site manufacturer to do?

Whether Bowron and others will be satisfied with the recent updates to Revit and Inventor remains to be seen.

At this point, he says that Catalyst Offsite is forced to use Revit, simply because it’s ubiquitous. “Architecture schools are churning out Revit users,” according to Bowron. There are now two generations of architects who have been schooled on Revit, which means there’s a big pool of architects who know how to use it.

Catalyst Offsite’s Julian Bowron says that while the company uses Revit to design its modules, it’s not ideal.

SolidWorks users are more likely to come from the automotive, aerospace, or machinery industries, which means it’s harder to find someone to design a building in SolidWorks than to find someone who can use Revit.

SolidWorks talent is also more expensive. Countless Revit users are working as interns in architects’ offices making $40,000 annually, or even less. By contrast, Bowron says Catalyst Offsite might pay a senior SolidWorks design manager $65 per hour, or $130,000 a year, while an intermediate SolidWorks designer might make $80,000. “Hiring a manufacturing-capable person is a significant challenge for an off-site manufacturer who wants to hire a designer.”

However, Bowron thinks that, ultimately, getting a model designed in Revit rather than in SolidWorks – or one of the other fabrication-ready software tools – is a “false economy.” His view is that off-site manufacturing companies need to train someone in-house to use fabrication-ready design software, or hire someone who can use it.

He says that while traditional builders might manage with a relatively low level of detail in their models, manufacturers need models with a high level of detail and accuracy. “The bottom line is that modular construction is manufacturing, not construction.”

Zena Ryder is a freelance writer who writes about construction for businesses, magazines, and websites. Find her at zenafreelancewriter.com.

Resources mentioned in this article:

Autodesk’s Research Community https://www.autodeskresearchcommunity.com/h/s/5mVuV4mKIKE3UivXM2ob6F

Autodesk’s Revit Ideas forum

https://forums.autodesk.com/t5/revit-ideas/idb-p/302

https://letters-to-autodesk.com/

https://balkanarchitect.com/

An excellent working and professional presentation.

We will wants to learn more about BIM AND RIVET TOOLS etc

Regards

ADIL AKHTAR

MEP CONSULTANT