by Daniel Small

One reason is massive waste on the factory floor. Research shows how we improve

- New field study has quantified a massive amount of wasted effort in modular factories

- Better training and improved processes can eliminate much of this waste

- Waste reduction will yield big profit and productivity gains

It’s a good time to be in modular construction. Modular awareness is growing, we’re getting a ton of buzz in the media, and potential market share is projected to grow by 200 to 400% over the next decade. That’s great news for the industry.

Of course, all this comes as no surprise to us true believers: we tell everyone who’ll listen that modular construction — like other offsite technologies — is more efficient, faster, less wasteful and safer. It also provides higher quality than on-site construction.

But while these benefits will continue to drive demand for modular, the industry won’t be able to meet that growing demand until it overcomes some challenges. One of the biggest challenges is extremely inefficient manufacturing. This acts as a brake on modular’s ability to grow.

Modular’s Problem

The reality is that the industry is still performing well below its potential.

- Many modular factories’ profit margins (like modular construction’s market share) are in the low single digits.

- Modular factories’ capacity limitations mean they’re unable to meet growing demand for housing units. This is stifling the industry’s growth.

- Factory-to-field coordination is often suboptimal, resulting in more callbacks, slower field finishing, higher costs and schedule delays.

- Although some pioneers are pushing the envelope in automation, many modular factories’ processes are essentially manual construction under a roof.

How do we fix these problems? I recently partnered with the Modular Mobilization Coalition (MMC) to answer that question.

To ensure a good cross-section of current factory stock, we partnered with five MMC affiliate factories on the research. All of them were building wood-frame multi-family and commercial projects when we visited.

We concluded that if these factories put some work into improving their processes, they could build more projects in less time and for greater profits. Let’s look at the numbers.

(This column is a high-level summary of our research results. A far more detailed report will be published soon. Please email me at [email protected] to request a copy.)

What We Looked At

Our research had two primary objectives:

- Measure the current installation efficiencies for various product categories. Our goal was to establish baselines against which to evaluate future optimization work.

- Benchmark and compare the modular factories with one other. This would provide concrete, data-backed insight into how they’re currently doing.

The factories we studied varied in age, facility size, dominant product, plant layout, employee count, extent of automation, revenues and more. We selected this mix to minimize correlation bias in the data.

We documented and analyzed installation processes for several product categories. Documentation consisted of five days at each factory, video-recording installations and interviewing workers. In all, we gathered well over 300 hours of video footage.

The installations we documented included:

- Kitchen cabinets

- Countertops and sinks

- Interior doors

- Enclosure insulation (floor, wall, and ceiling)

- Duct and pipe insulation

- HVAC units and ducting

- Building wrap/WRB

- Window and door flashing

(We also looked at installations for other categories, including framing and cladding. Those will be detailed in the full report.)

Analysis of the video clips included carefully identifying, categorizing, and logging the activities of each employee involved in each installation process. We categorized every second of activity according to Lean Six Sigma definitions. Activities were defined as:

- Value-Added (VA): activity the customer pays the factory to do, or

- Non-Value-Added (NVA): multiple sub-categories such as waiting, motion, transportation, rework, QA/QC, etc. These are direct costs that we seek to help factories reduce or eliminate.

We then calculated the Process Cycle Efficiency (PCE) for each product installation process by dividing VA time by total installation cycle time.

The Results Were Shocking

What we discovered was worse than expected. These results were strikingly consistent across all five of the very different factories, so we suspect they are typical of the industry as a whole.

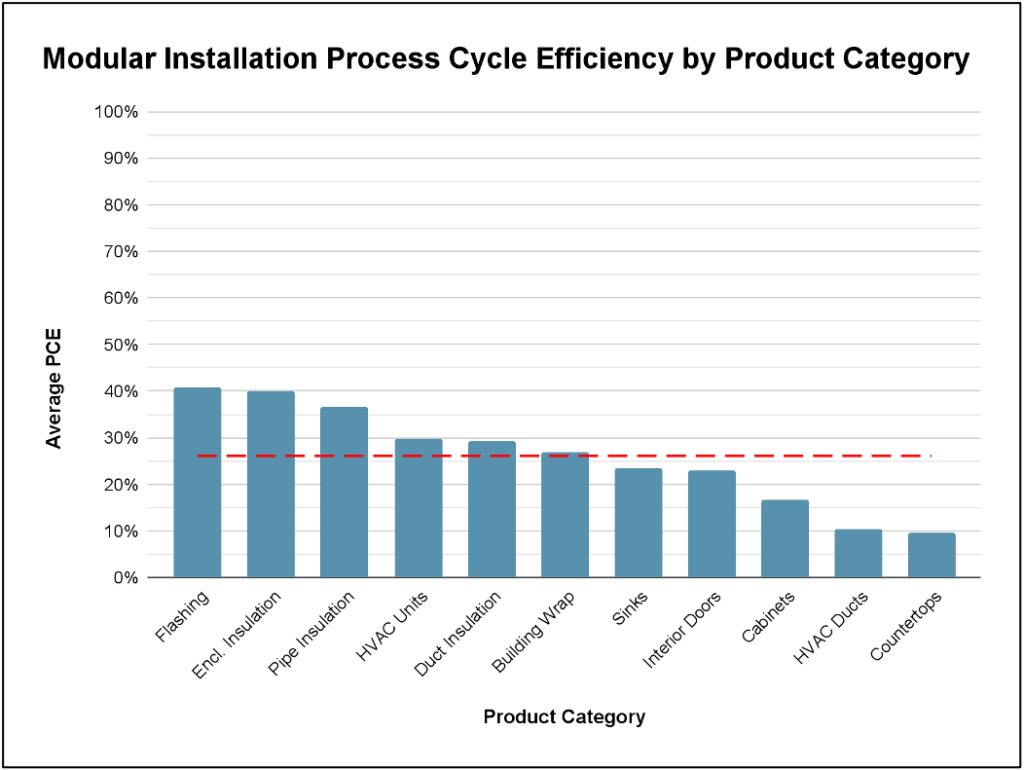

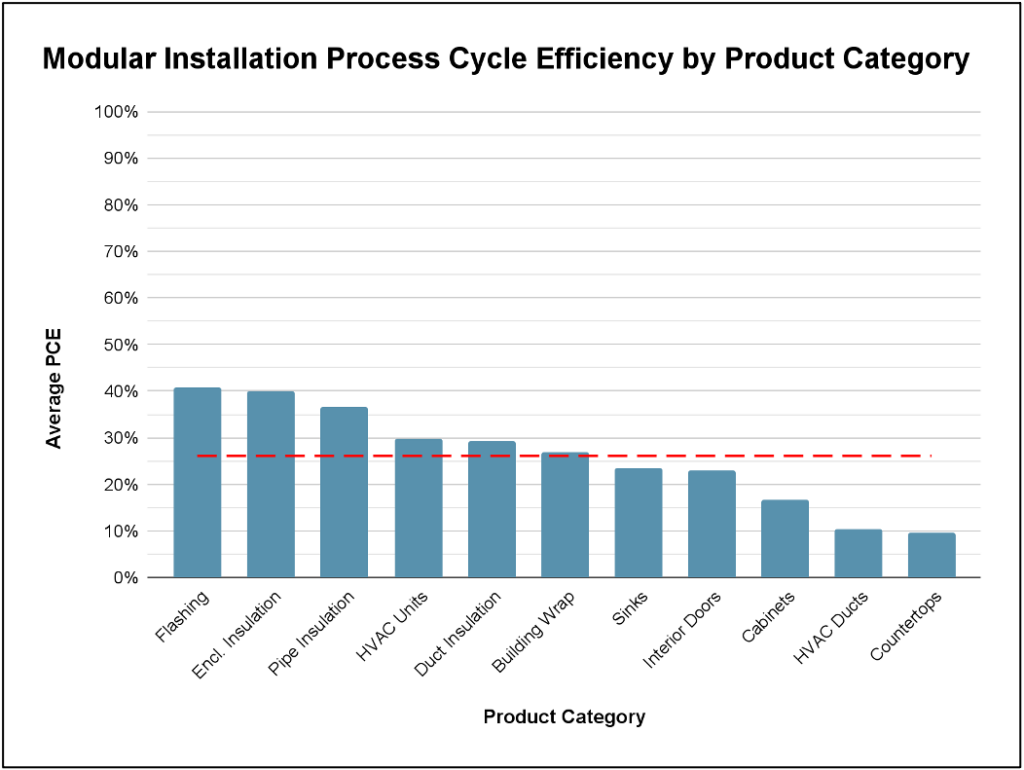

As Figure 1 shows, average PCEs for all product categories ranged from roughly 40% to 10%, with an average PCE of just 26%. That means the installations we measured included 74% NVA.

In other words, nearly three-quarters of the time spent on these processes was non-productive. The worst cases included about 90% wasted time. To call this wasteful is an understatement.

The obvious question is how to eliminate this waste.

How We Improve

I want to be clear that these results have only increased our optimism for the future of industrialized construction. Why? Because they expose big opportunities for improvement upon what is already a far superior method of construction.

In other words, modular has the potential to be far more productive, and therefore far more dominant, than it is now. We believe that the PCEs we observed could be increased by 100 to 500%, dramatically improving profitability, throughput, quality, and productivity. But getting there will take a lot of work.

Below are some practical steps every offsite construction factory can take to realize these gains:

- Better Processes – Utilize Lean Manufacturing and Six Sigma methodologies to reduce NVA time from friction, delays, and unneeded manual steps. These methodologies have proven their value for more than 70 years in nearly all industries — including most building product manufacturers. Modular factories can tap into an extensive network of trainers and existing users for help.

- Better Training – Use training to create a culture of continuous improvement. A simple start would be to teach workers the concepts of Lean Manufacturing and waste reduction. Most workers want to be productive, and when they understand how to spot waste, they will begin suggesting ways to reduce it. Listen to them.

- Optimized Materials – Partner with innovative suppliers to develop offsite-optimized materials to address manufacturers’ needs. For instance, unit sizes for everything from drywall to roofing are optimized for manual jobsite handling, but factories would be more efficient with larger units. Getting suppliers’ attention will require cooperation between modular manufacturers.

The bottom line is a full shift to modular, and other industrialized construction methods, will require new skills, new ideas, and cooperation among everyone in the industry.

Those who take the lead will be rewarded for their efforts. Although we have yet to work with a factory to implement these changes, my guess is that the labor hours needed to manufacture each modular project could be reduced by up to 40%, and overall costs cut in half. This will put the industry in a better position to meet rising demand.

Now, let’s take modular construction to the next level.

Daniel Small is a Denver-based management consultant to the building industry. He specializes in Lean Construction and Manufacturing and Six Sigma methodologies. Contact him at [email protected]

Where does rough framing, electric rough-in, drywall rough hang, and drywall finish fall on the PCE lineup..?

Daniel, great report, and it is a start at where some of the wasted time is in modular home construction. But before the house goes into production, they have to get the order. My 17 years of experience with seven different factories have taught me that modular home construction has a long way to become mainstream and more profitable.

For every order, I take, I have over 20 hours of back and forth. And that means the factory has at least that amount of time on every order they are working on. Every revision takes 10 to 14 business days. The invoicing/estimating software has not changed in over ten years and is very cumbersome. This is 2022, and we are working with last-century software and processes. I have suggested to three of the factories ways to increase the order times but they refuse to listen. They know what they are doing because this is how they have always done it. Then I learn from your report they are operating on slim margins. It’s hard to imagine having that kind of investment for so little return and not being willing to try something different.

At times I get very frustrated with the whole slow process. Consumers can build their cars and order them online. Consumer can buy an existing house online in a matter of days. Consumers can buy a used car and have it delivered to their homes. But I cannot get a single factory to spend 30 minutes with a customer on a zoom call to hammer out plans, going from nine revisions to two or three. Instead, I have to go back and forth for weeks, even months, before we get to a plan where the customer is comfortable with placing an order. If we could reduce the order time we could get in more orders.

Really good article, although I think this mindset/ approach should be considered in the earliest stages of design. Much easier to start with products and materials that already offer manufacturing and assembly efficiencies. This also drives closer and more dynamic supplier relationships which in turn drives supplier innovation for OSM which as you point out isn’t really happening in any significant level yet

[…] a more detailed explanation of Process Cycle Efficiency, see my article “Why is Modular Falling Short of Its Potential?” in the February 2022 […]