A recent poll offers a glimpse into offsite manufacturers’ embrace of digital technology.

Technology is in the process of transforming offsite manufacturing, and a recent poll I conducted sheds light on where we are in that process.

My poll asked a simple, yet profound question: “Which of the following five technologies have you implemented in your factory?” The list consisted of Building Information Modeling (BIM), Robotics, Automated Tables, Design for Manufacture and Assembly (DfMA), and Artificial Intelligence (AI). Here’s my analysis of the results:

Photo courtesy of Homag

Automated Tables: Leading the Change – 30.8%

Automated Tables streamline manufacturing by automating movements and tasks that traditionally require manual labor. Their 30.8% adoption rate suggests a desire for technologies that directly enhance production line efficiency. They offer a blend of simplicity, efficiency and cost-effectiveness, and are often a first step towards more sophisticated automation.

BIM: The Foundation of Digital Construction – 23.1%

BIM technology enhances efficiency and reduces cost by making it possible to visualize projects in a simulated environment before they’re built. Its relatively high 23.1% adoption rate reflects an industry moving towards digital integration, with BIM acting as the cornerstone.

DfMA: Innovating Construction – 19.2%

With a 19.2% adoption rate, DfMA is catching on as companies seek to minimize waste and optimize production. It’s a foundational element of Industrialized Construction, and also supports sustainable manufacturing goals in an industry seeking to become smarter and greener.

AI: The Future is Now – 15.4%

Artificial Intelligence (AI) offers capabilities in predictive maintenance, quality control and supply chain optimization. Its 15.4% adoption rate may reflect its nascent stage, with a lot of manufacturers taking a wait-and-see approach. However, AI’s impact on the industry promises to grow exponentially as it matures and becomes more integrated into manufacturing ecosystems.

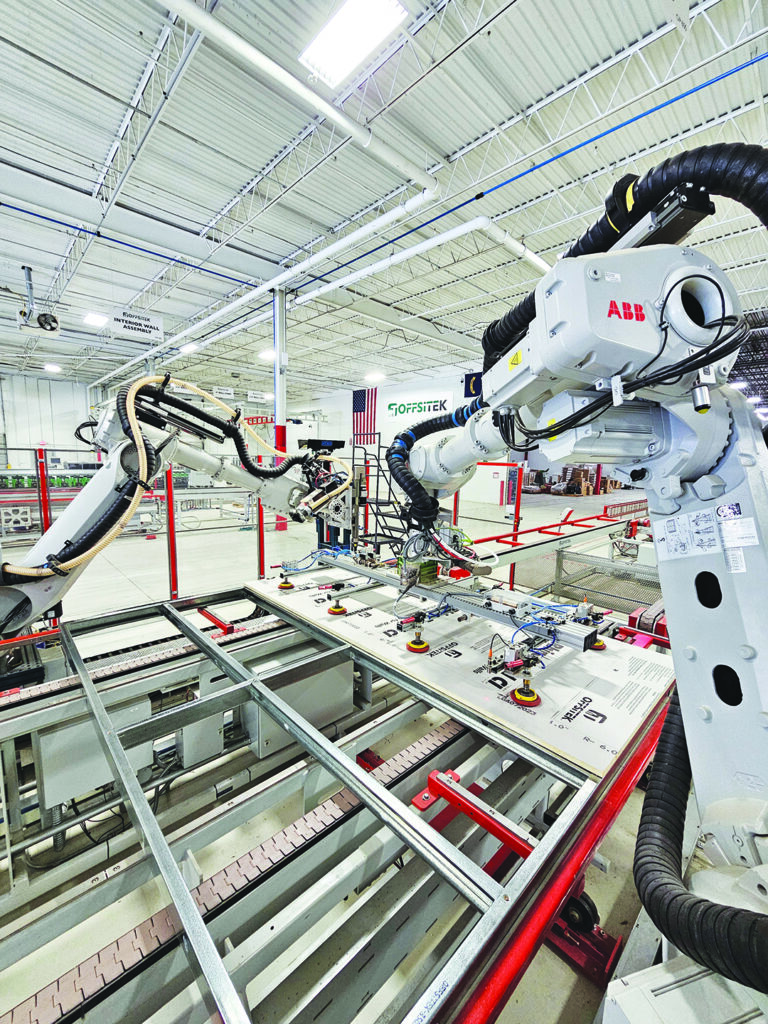

Robotics: Streamlining Operations – 11.5%

Although robotics has long been a staple in other industries, offsite manufacturers’ 11.5% adoption rate indicates caution. Robots offer unparalleled precision, productivity and efficiency, but require a high-cost investment as well as workers with specialized skills. As this technology becomes more adaptable and affordable, however, its percentage should grow, indicating further automation of tasks that are dangerous, dull, or dirty.

My Conclusion

These results indicate a cautious, yet steady, embrace of innovation. Each technology, from BIM to AI, is playing a unique role in the transformation of our industry, offering solutions to age-old challenges, and opening new avenues for growth and efficiency. The diverse adoption rates highlight the varied approaches factories are taking based on their specific needs, capabilities and strategic visions.

I predict that all of these technologies will become essential to a competitive manufacturing strategy. Their continued evolution and integration will redefine what it means to be a leader in offsite manufacturing. The journey towards a fully digitized, automated and efficient manufacturing landscape is underway.

Gary Fleischer is Editor-in-Chief of Offsite Builder magazine. This column was originally published on his blog: ModularHomes.com.