Some interesting new offsite products.

Earlier this year, I attended the International Builders’ Show (IBS) in Las Vegas for Offsite Builder, in search of products that could be useful in offsite construction methods. From products that improve speed, to products that support disaster mitigation, here are five worth exploring.

Fire Resistant Panels

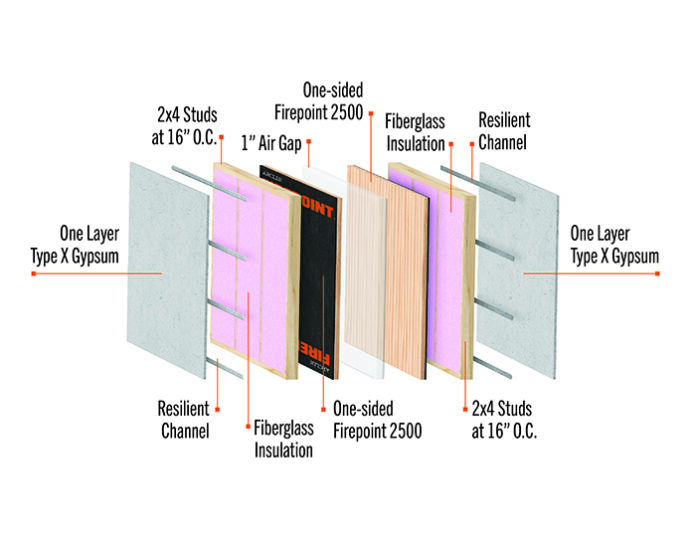

With the increase of wildfire incidents and insurance costs across the US, fire resistant products can only become more popular. Arclin, a materials science company based in Alpharetta, Ga., introduced their Firepoint wall panels during IBS. The panels are fire-resistant and can be used in both single-family applications and multifamily construction, eliminating the shaft liner in partition walls as well as gypsum in exterior walls.

Interior and exterior wall assemblies (Type III and V) using Firepoint’s wall panel solution are certified by the ICC for 1-hour and 2-hour wall assembly burn tests for both residential and non-residential applications. The panels are lightweight, resistant to cracking, chipping and flaking, and are shipped like any other panel product — bundled, wrapped and delivered on a skid.

Arclin makes the panels by applying intumescent technology over standard plywood. The coating slows the spread of fire by expanding and charring when exposed to high heat and flames, providing 53% more fire resistance than standard code requirements (per ASTM E-119 in a third-party accredited lab). The product also offers a 20-year performance warranty (per ASTM E-119 in a third-party accredited lab after a 6-month weather exposure). For more information visit www.firepoint.arclin.com.

Aerogel Insulated Panels

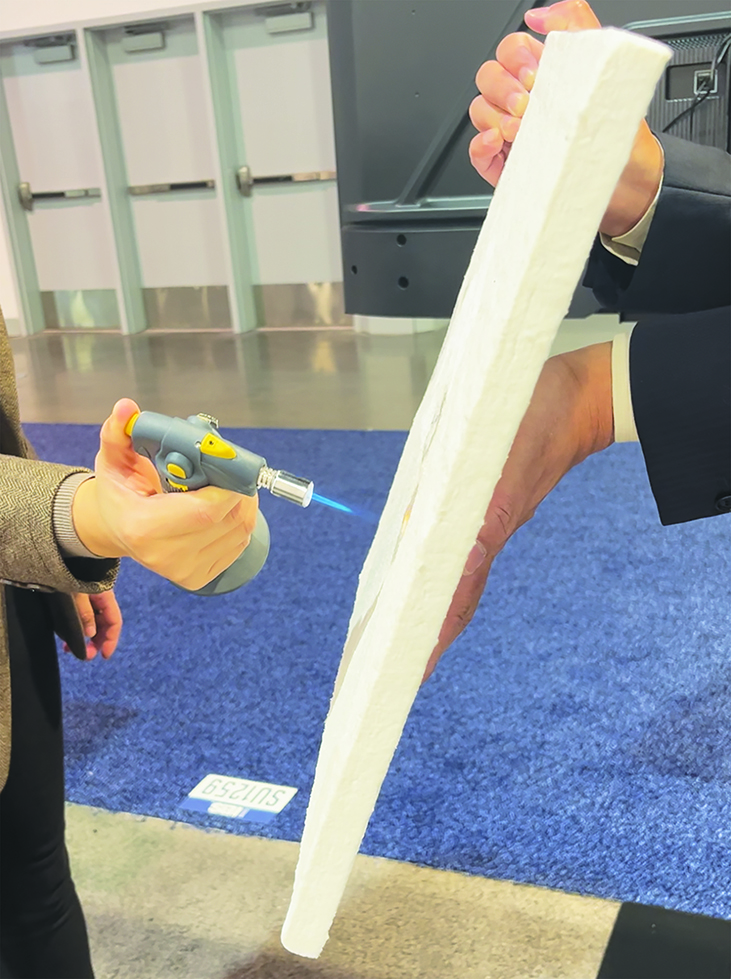

Aerogels are a very effective thermal insulator; in fact, NASA used aerogels in early space exploration to insulate equipment from extreme temperatures and worked with industry in the 1990s to create the world’s first flexible aerogel blankets. The material is used today in building construction, industrial insulation, cryogenic applications and apparel.

Now, Eureka Modular, a modular manufacturer in La Mirada, California, is on track to bring non-structural panels made with aerogel composite inorganic fiber to the US.

When used in a wall assembly, these insulating panels (with an R-value of 8 per in. and a density of 15 lbs. per cu. ft.) could potentially replace the use of both fireproof panels and rock wool, while also providing sound insulation and attenuation, with a sound absorption coefficient of 0.406.

They can also be used in fire-rated assemblies to replace gypsum and could possibly reduce the number of fire protection layers normally required for a given hourly rating. ASTM E-119 testing will be completed later this year on a structural wall design using the panels that Eureka expects will receive a two-hour fire rating.

Aerogel panels will be offered in ½ in. and 1 in. thickness. Standard sizes from 4 x 8 to 5 x 12 ft. will be available, with a reported starting price of $3 per sq. ft. For more information visit eurekamodular.com/pages/fire-resistant.

Photo courtesy of: Heather Wallace

Better Sheathing

The Innovation MgO Series of products from US MgO in Wilmington, N.C., consists of building materials made from a proprietary magnesium oxychloride (MOC) cement formula and other inorganic materials. Thanks to rigorous product manufacturing, testing and quality control standards the company says that its panels can outperform wood-based, gypsum-based and Portland cement-based panels in structural strength and durability. All Innovation MgO Series products are also naturally fire-resistant.

The company’s ½ in. wall panels are approved for both exterior and interior use in building types I, II, III, IV & V and can be attached to metal and wood studs. Wall panels can replace interior and exterior gypsum and offer better fastener pull-out strength, making them an ideal attachment base for many types of claddings. Innovation MgO Subfloor Panels offer a water resistant, smooth and fire-resistant flooring underlayment solution. For more information visit https://usmgo.co/.

Wood-Cement Composite Walls

The Walls of Troy offers ½ in. thick structural housing panels made from wood-wool blended with Portland cement. Constructed in their Brunswick, Georgia factory, panels are cut to size and shipped to site and can be used for both single-family and multifamily projects. A 2,000 sq. ft. structure would require approximately 30 panels and the factory can currently produce about 90 panels in an eight-hour shift.

With a standard size of 9.5 ft. high x 6 ft. wide, the panels have been tested by Underwriters Laboratories and were shown to be fireproof with zero flame-spread and a Smoke Developed Index (SDI) of 0 (zero) — meaning the product produces no smoke when burned. They are also waterproof and anti-microbial. They can be directly plastered on the interior, and allow for direct adhesion of exterior finishes.

While these types of panels have been used in European residential and commercial construction for decades, this is the first time they have been available in North America. The first home in the US to use these panels should be completed in late 2025 near the Tribal Nations in Oklahoma with an end goal of building attainable veteran and elderly housing projects. The company is also exploring building additional factories in collaboration with other Native American tribes around the country. Learn more at https://wallsoftroy.us/.

Prefab Tile For Modular Homes

Six3Tile, based in Lancaster, S.C., is helping manufacturers streamline production with a pre-finished, easy-to-install, professional-grade tile panel product that offers a high-end aesthetic while decreasing installation time and labor costs.

Designed for both residential and multifamily applications, the product can be used for kitchen backsplashes, bathroom showers, tub surrounds and more. It’s made from a high-durability polymer composite, and installs easily with a few tools and some construction adhesive. Non-sanded grout can be used to give it a “real tile” look and feel. Factory workers can complete installation in a modular home and, unlike ceramic tile which can crack during transport, the panels are designed to withstand the rigors of shipping.

A Home Innovation Research Labs’ time study showed that Six3Tile could be installed 55% faster than ceramic tile in backsplash applications, and 64% faster in shower applications. It also withstood durability testing.

Clayton Homes Appalachia, a manufactured homebuilder in Andersonville, Tenn., saw immediate cost savings, improved production output and reduced post-installation service using Six3Tile. Their goal with the product is to increase production from about two ceramic tile showers a week to more than 20.

From classic subway to hexagon and herringbone styles, Six3Tile is available in gloss or matte finish and a variety of Sherwin-Williams whites, neutrals and grays, as well as custom colors. It also comes with a 5-year limited warranty. For more information, or to request a sample, visit www.six3tile.com.

Heather Wallace is a freelance writer and industry engagement specialist with over two decades of experience in various areas of the building industry. She has covered topics on construction, technology, workforce development, green building, and sustainable living.

Photos provided by the manufacturers except where noted.