The perks and pitfalls of prefabricated kitchen and bath pods

- Although demand for kitchen and bath pods is being driven by large corporate customers such as hotel chains, they can also make economic sense for a modular manufacturer

- The key to making pods cost-effective is standardizing designs as much as possible and producing them in sufficient volume

- The use of pods requires that designs be finalized before construction begins and that the building layout ensures each pod can be easily dropped into place and connected to utilities

- Success with this approach requires some education for architects, engineers and general contractors

Patrick O’Callaghan has over 20 years of international construction experience, both as a manufacturer and as a contractor. Since 2010, he has been the CEO of Off-Site Engineering Solutions FZE, which is based in Dubai in the United Arab Emirates (UAE). The company designs and manufactures kitchen and bat pods, (as well as other modular components), in 14 prefabrication facilities across the Middle East.

They also offer consulting services. They help building owners gain maximum benefit from prefabrication, advise manufacturers on how to set up prefabrication plants, train staff on how to efficiently produce prefabricated components and educate designers on how to turn traditional 2D drawings into 3D BIM designs, from which production drawings can be extracted.

Based on his experience in the industry, we asked O’Callaghan about the advantages, pitfalls and opportunities in manufacturing bathroom and kitchen pods.

Demand for Pods

O’Callaghan says that architects and engineers often slow the adoption of prefabrication. “They feel exposed by their lack of knowledge of prefabrication and so tend to ridicule it.” He says they often consider it something the contractor can choose to use or not use and thus not something they need to worry about.

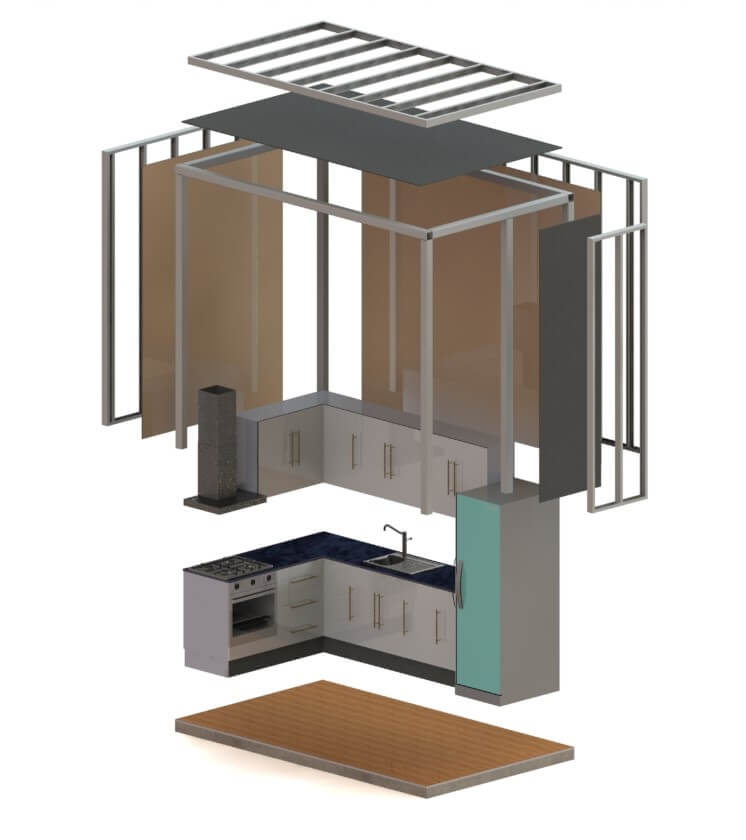

The problem with this attitude is that prefabrication must be considered during the design stage. “There are small, but vital, tweaks [to the building design] that are necessary to make efficient use of prefabrication. You should be able to drop a bathroom or kitchen pod into place and connect it to the plumbing and electrical systems, just like installing a washing machine or a dishwasher.”

Pods also must be ready for delivery as soon as the building is ready to have them installed. “Design details need to be approved and materials procured much earlier than in traditional construction. There is generally a higher design load upfront, but this results in time savings later.”

This places demands on the design team, so it’s no surprise that, according to O’Callaghan, owners — not architects, engineers, or contractors — are the ones driving demand. Whether the project is a student dorm or a luxury hotel, “they understand the benefit of speed. They get heads on beds sooner and a quicker return on investment.”

Owners also recognize that prefabricated bathrooms and kitchens “have fewer defects, are of higher quality and score points on various green building metrics — such as LEED and Estidama [a rating system developed in the UAE].”

One way prefabrication helps score ‘green’ points is that it results in less waste than traditional construction. O’Callaghan explains, “In manufacturing, 1% or 2% of raw materials end up as waste. For on-site construction, that figure is 7% to 15%.”

He says that in a factory it’s typical for the collection and appropriate disposal of harmful solvents, paint tins and glue containers to be comprehensively and transparently tracked. That’s in sharp contrast to conventional construction, where “no one really properly deals with this issue.” The result is that harmful products are disposed of along with the regular waste.

Thinking Ahead

Architects who haven’t used prefabrication before will need education on this way of building. Incentivizing them should be relatively easy for an entity such as a hotel chain that builds a lot of properties and uses the same handful of architects for all its new hotels.

It’s not only architects and engineers who need educating, though. Prefabrication also requires contractors to change their thought processes. As O’Callaghan puts it, “If you asked a contractor about the details of a bathroom early in a project — such as how the floor tiling will meet the doorway threshold, or where the soap dish should be placed — the guy’s head would explode.”

But with prefabrication, such details can’t be left to figure out later on the jobsite; you need to settle them early in the design. “We need to finalize the design so we can create a digital model and produce an actual ‘first article’ for the client to see. They might want to change aspects of it and we’ll make those changes [before we start manufacturing].”

Efficient Manufacturing

Architects also need to understand the importance of standard pod layouts. After receiving the architect’s drawings, much more detailed shop drawings are created by the fabrication team. “Minimizing the number of layouts greatly reduces the prefabricator’s design load and reduces costs as a result,” O’Callaghan says.

Of course, clients tend to want pods designed specifically for each project. But, like any manufactured product, cost-efficiency is greater when one client buys in high volume and with few design variations. “The minimum number of bathrooms for breaking even on a project is around 120 or 130 pods,” O’Callaghan says.

For this reason, Off-Site Engineering Solutions generally avoids working with small boutique hotels because, along with their low volume, “they tend to want different layouts. The amount of time that goes into design isn’t worth it for us or the client,” O’Callaghan says.

New clients are more difficult to work with because they don’t already understand how important it is to reduce the number of layouts. Recently, O’Callaghan’s company had a new client in the Middle East who was planning a 1200-room hotel. Initially, the bathrooms were all supposed to be different. “But we talked it through with them and eventually settled on four different designs.” Those four designs included right- and left-hand variations of the same bathroom “so that they can go next to each other and have a joint riser between them.”

He says that many hotel franchises are now standardizing how they order their bathroom pods. They have adopted bathroom layouts that are “pod-friendly, easily manufactured and easy to install.” They understand the benefits of prefabrication as well as know how to design for manufacturing.

Can Pods be Stockpiled?

The company doesn’t usually keep pods in stock because clients prefer specific designs for each project (keeping in mind the 120-130 pod volume for breakeven). However, there are exceptions.

For instance, if a particular client has enough guaranteed volume, it might make sense to stockpile pods for them. “Marriott and Ramada bought thousands of bathroom pods from us,” O’Callaghan says. His company knew the hotels’ brand standards and could anticipate what they would need for future projects.

“Also, a decade ago, when we were manufacturing in Ireland, we made what we called a vanilla pod,” O’Callaghan says. They were bathrooms for student accommodation and had a very simple layout, plain white tiles, readily available bath fixtures and so on. “We could build them to stock when there was a slowdown and sell them later.”

Ensuring Cash Flow

With a conventional building, materials and products like lumber and floor tiles are delivered to the jobsite. The client’s representative confirms they’ve been delivered and the GC is paid 65% or 70% of the cost of those materials, O’Callaghan explains. That cash flow is essential for the GC.

But with prefabricated components, raw materials are delivered to the plant, not the jobsite. So when the client’s representative visits the jobsite, they don’t see those materials, which makes them reluctant to pay an installment.

“But manufacturers need cashflow too,” O’Callaghan says. “They will starve if they don’t get paid until the modules or pods are delivered to the site.” He also points out that the materials needed for prefabrication — tiles, cabinets, bathtubs and so on — are not part of the manufacturer’s inventory; instead, they belong to each client’s specific project.

To overcome this problem, O’Callaghan’s company introduced an audit system. “The materials and finished pods needed for each client’s project are all stored in areas specific to that client. Everything is then valued, photographed and documented for the client’s representative to audit.” Once the client’s representative can confirm the materials have been delivered to the factory, the manufacturer is paid an installment.

Modular Builders Use Pods, Too

Bathroom and kitchen pods are used mostly as elements of prefabrication in otherwise conventional projects. Modular builders tend not to use pods and instead build bathrooms and kitchens in their own modules, just as a traditional subcontractor would in a site-built structure.

However, modular builders can make use of pods. They can either buy them from a third party who specializes in pod manufacturing or can manufacture pods themselves on a separate line and drop them into their modules.

O’Callaghan believes that “there’s no way a modular builder can accomplish huge volume without using pods — either pods they manufacture themselves and keep in stock or that they source from an external supplier.” This is because when bathrooms and kitchens are conventionally installed in modules, it holds up the line and reduces throughput. In contrast, a pod can be placed quickly and the module continues its finishing process.

In addition to the speed of production, O’Callaghan mentions other reasons modular builders might want to use pods.

Quality. A modular builder may not have access to the skilled labor necessary to produce the highest-quality bathrooms and kitchens. Pods let them outsource this part of this work to specialists.

Cost. If pods are manufactured where labor is cheaper than the modular builder’s location, it might be cheaper to buy and install them than to build bathrooms and kitchens in-house from scratch. For example, pods manufactured in China could be installed in California.

Production volume. Modular builders can’t just lay people off when a project ends. They have permanent staff, not temporary subcontractors. They also have building and machinery overheads. These costs require constant throughput to support. The addition of a pod manufacturing line can open up another source of revenue. “When things are slow on the modular side of the business, you can still sell pods as a separate product and keep things ticking,” O’Callaghan says.