An interview on industrialization with Autodesk’s Amy Marks

by Zena Ryder

- The secret to growing offsite won’t be in incremental improvements of old processes.

- Industrialization is a whole new way of building that makes sense on different levels

- This way of building need not preclude interesting architecture.

- Good software is essential, but it needs to be customized for each manufacturer

What, exactly, is industrialized construction? How can the offsite industry move in that direction and what’s currently holding it back? We put these questions – and more – to Amy Marks (aka the Queen of Prefab), VP of Industrialized Construction at Autodesk.

Industrialization is the difference between handcrafting a unique piece of furniture and mass-producing identical pieces of furniture in a factory with lots of automation. In the latter scenario, there might be a handful of options, but variations are kept to a minimum for efficiency’s sake. Similarly, in construction, industrialization is the mass production of mostly identical buildings, with minimal variations.

This can happen in degrees. As a process becomes more industrialized, it becomes more precise, more automated, less labor-intensive, and faster. It also becomes more repeatable in that it yields identical products.

A good analogy is the fashion industry. “Custom, bespoke couture is expensive, and for people like J. Lo to buy and wear at the Grammys. The rest of us get our clothes off the rack. That’s what we need in housing,” says Marks. “There will always be a market for custom, bespoke houses, but we also need the housing equivalent of products from The Gap.”

While fashion and other industries are known for mass-produced products, construction lags far behind.

Why Does This Matter?

A more industrialized construction business would bring environmental benefits and efficiency.

Less waste. When a building design can’t be manufactured efficiently, material is wasted. Let’s say, for example, that someone designs a wall system with 7 ft. 11 in. studs. If the standard length of a stud is 8 feet, then an inch will have to be cut from each one— a waste of both materials and labor. Designing the wall system for 8-foot studs will eliminate that waste.

More housing. There’s a shortage of housing in many countries around the world, and the only way to fill the gap is to quickly mass-produce homes in factories. Some people assume that factory-built homes are of inferior quality to site-built ones, but that’s a misconception. In fact, the ability to manufacture housing units in a controlled factory environment should result in higher-quality products. Just consider the high-quality, mass-produced cars, furniture, and clothing we all use.

Business scalability. According to Marks, when a manufacturing business — including a panel or module manufacturer — becomes more industrialized, it can scale more easily. It’s hard to grow a business if it makes only custom products.

Marks emphasizes that the first step of industrialization is productization.

How to Productize

To productize you need to think of what’s being made in terms of repeatable specifics. This includes the materials and components the item is made from, the dimensions of the components, the processes used to make it, the order in which those processes have to happen, how long each process takes, and so on. Crucially, this manufacturing data must inform the product’s design. In fact, productization is the process of creating repeatable product designs that are informed by manufacturing data.

“There will always be a market for custom, bespoke houses, but we also need the housing equivalent of products from The Gap.”

This manufacturing data should be put into software like Inventor, Fusion, or Solidworks so it can be conveyed to manufacturing tools. “If manufacturers don’t know the details of what they make, they can’t buy tooling or automation equipment that will enable them to scale up,” Marks says. The data needs to be reusable — not just applicable to one building or project.

Of course, a lot of products that go into buildings are already productized—from roof shingles to refrigerators to heat pumps and so on. Marks believes it’s time that the buildings they go into becoming productized.

“I’m working with a modular customer right now who is doing product development,” Marks says. “A volumetric module is an aggregation of products. This company is productizing the chassis, the MEP system, the interior finish, and the exterior finish — because they want to be able to mix and match those different products.”

Won’t This Lead to Boring Buildings?

Productization is a gradual process that will first manifest itself above the ceiling, behind the walls, and under the ground with the heavy MEP components, Marks says. The invisible elements of a building.

In her view, architects are happy when these components exist as products, with digitally defined parameters. An architect can plug that product data into the digital model and design around it. “Instead of spending time drawing mechanical equipment, they can spend more time on the aesthetic elements that are why they became architects in the first place,” Marks says.

Sophisticated, mature architects understand that there are lots of products that could inform their designs that have nothing to do with the aesthetics of the building, Marks says. “Productization doesn’t shackle architects. It frees them to focus on the parts of design where they enjoy being creative.”

The Role of Software

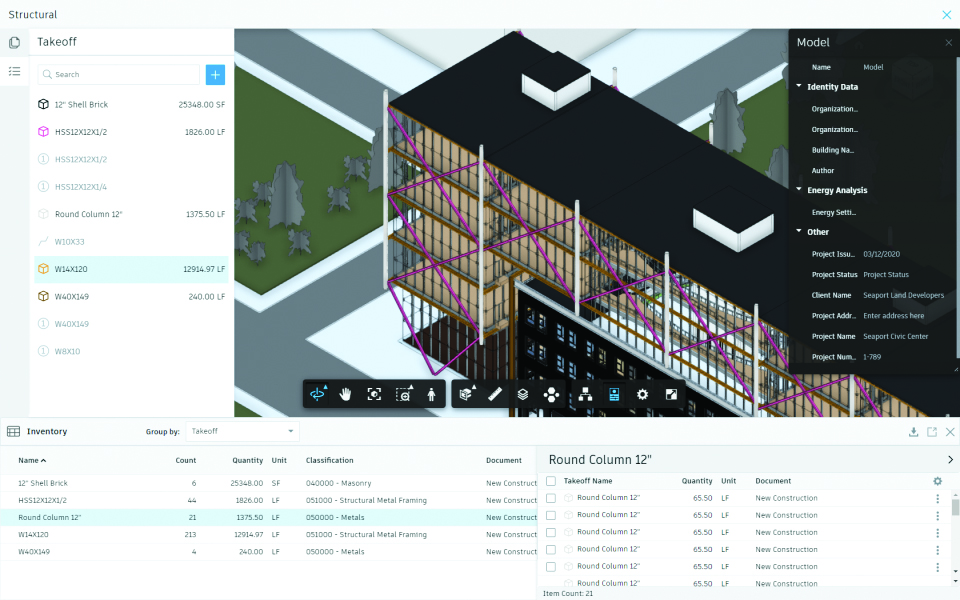

Using BIM [Building Information Modeling] software is necessary because building designs need to be informed by manufacturing data. But if the software isn’t informed by the manufacturing data, then a 3D design could still be unbuildable in practice.

Software makes it possible to associate data with specific physical products like the MEP components mentioned earlier. “A physical product has a data package associated with it. The data package travels anywhere across a software platform with all the data inside it,” Marks explains.

But not everyone needs all the data. For instance, an architect will need the physical dimensions of a heat pump to include in the model of the building, but they needn’t pay attention to, say, the sustainability-related data that’s also in the heat pump’s digital package.

What are the roadblocks?

Marks points out that each of us has different apps on our phones, to best serve our lives. One person has apps for dating and for reading the newspaper, another has apps for ordering takeout and for voice recording.

Similarly, an offsite manufacturer will need software products tailored to their needs and goals. “People wish it was simpler than it is to get the software and other technology that’s right for them,” Marks says.

Two manufacturers with different needs may need to use completely different software to make their companies function best. “In the future, we’ll have enough data to be able to make suggestions for software combinations that a manufacturer is likely to need, based on personas we’ve developed over time. But we’re not there yet.”

Software evolution

Marks says that convergence has been the biggest development in software over the past few years.

Convergence is when various software tools can ‘talk’ with each other because they can be used on the same software platform. (The idea is similar to the iPhone iOS, which is a platform that can have many different apps on it.) A result of this convergence is that data from component manufacturers can ‘meet’ an architect’s design software on the platform.

Autodesk is an example of a platform, with multiple different products — software tools like Revit and Fusion — that can be used on it.

She says that industrialization will require each manufacturing company to have the right platform, the right software tools, and the right data. The combination they need is going to vary depending on what they make and how they make it.

Zena Ryder is a freelance writer who writes about construction for businesses, magazines, and websites. Find her at zenafreelancewriter.com.