The AI Production Brief is the simplest upgrade a modular factory can make. And it doesn’t cost a dime.

Every year, the offsite construction world gets hit with new promises of automation, robotics, “smart factories” and AI-driven everything. And every year, most modular factories give the same look: Sounds great, but who’s paying for all of that? The gap between the dream of innovation and the reality of factory operations has never felt wider.

That’s why this low-cost, zeroinfrastructure AI improvement is catching on so quickly. It’s not robots. It’s not software. It’s not consultants.

It’s simply using AI to create a daily Production Brief so that everyone enters tomorrow with the same playbook.

The Sleeper Hit of Factory Workflow

Can you guess what one of the biggest drains on productivity in modular manufacturing is? It’s not incompetence. It’s not laziness.

It’s confusion.

• A missed email from a GC.

• A plan revision nobody forwarded.

• A product or material that arrived late.

• A station waiting for instructions.

• A Quality Control issue discovered yesterday, but forgotten this morning.

When a factory starts the day with missing or conflicting information, the next eight hours turn into a scavenger hunt. The morning huddle becomes a debate about which version of reality is correct. Supervisors walk the floor trying to piece together updates from four different departments. And every time someone needs to ask, “Did anyone hear about this?” the clock keeps ticking and production keeps slowing.

AI doesn’t have to be complicated to make this better. You simply feed it the chaos from the previous day and let it produce a clean, organized, easy-to-understand Brief. Everyone walks in the next morning already aligned, already focused, already clear on what matters. And suddenly, productivity rises without anyone even noticing why.

The AI Production Brief

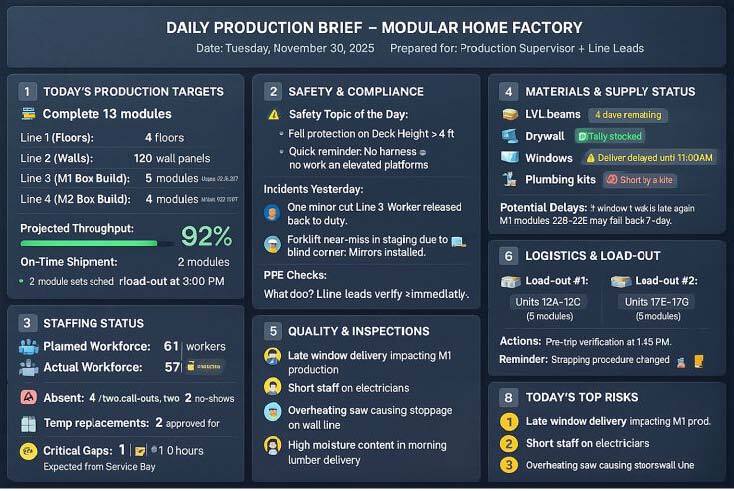

The idea is to gather everything that normally gets lost in the shuffle — emails from project managers, QC notes, updated drawings, materials that didn’t arrive, internal messages, inspection reports and even snapshots of scribbled notes — and drop it all into the AI tool, which then synthesizes the information and lays out exactly what the factory needs to know for the next day

The Brief explains the critical tasks, the priorities for each station,the items QC is watching, the material delays that affect sequencing, the staffing or safety concerns, the conversations that engineering or drafting need to complete and the risks that could derail production if ignored.

It’s the factory equivalent of walking into your day with a freshly cleaned desk. Everyone breathes a little easier because the clutter is gone and the path forward is obvious.

Benefits for Younger and Older Workers

Younger workers will obviously like this. Millennials grew up bouncing between emails, texts, apps, notifications and shifting priorities. They’ve always been forced to filter enormous amounts of information quickly

When they see a tool that does the filtering for them, they instantly understand its value.

They understand that this isn’t technology for technology’s sake. It’s clarity. It’s relief. It’s eliminating the tedious work of reminding, repeating, double-checking and correcting. For younger managers who already think in terms of digital organization, this feels natural.

But it’s not just younger people who respond. For everyone, it feels like someone finally turned on the factory lights a little brighter.

Implementing in Three Easy Steps

Start by choosing whichever AI tool your factory already has access to — ChatGPT, Copilot, Claude, or any system your office staff already uses. There’s nothing extra to buy, nothing to install and nothing to train.

Next, use the same consistent prompt every day so the AI learns the rhythm of your production line. The prompt frames the AI as your “Production Brief Assistant,” instructing it to analyze everything you upload and produce a clear one-page summary of tomorrow’s priorities, risks, changes and communication needs.

How do you write a good prompt? By asking your AI program. The details will vary by factory, but I’ve included a sample prompt here, written by ChatGPT. In fact, it offered to produce different prompts for different parts of the factory.

Finally, distribute the finished brief. Print it, email it, text it, hand it to line leads, read it at the morning huddle — whatever fits your operation. The important thing is that every department sees the same information before the first tool is picked up.

Immediate Benefits

The daily Brief will start shrinking morning meetings almost instantly, because there’s no need to re-explain what the AI already clarified. Supervisors begin their day with a head start instead of running around gathering scraps of information. Problems show up in the Brief before they show up on the floor, giving the team time to fix them.

Communication between the floor and the office finally feels synchronized. People aren’t waiting for answers that were buried in someone’s email. Engineering knows what drafting owes them. QC knows which modules require attention. Transport knows what day they need to be ready and what might delay them. And perhaps the biggest change is the sense of calm that settles over the building. When everyone starts the morning with the same map, the day stops turning into a surprise party.

A New Way of Management

If yesterday was confusing, tomorrow should not be.

AI-powered daily Production Briefs don’t overhaul your factory — they simply organize it. In an industry where delays cost thousands and rework can destroy a week’s profit, clarity becomes a competitive advantage. This is the rare form of innovation that requires no capital request, no downtime, no consultant and no technical training.

It’s just a habit.

A daily rhythm.

A small change that strengthens the entire factory.

And it all starts with one prompt.

Gary Fleischer is Editor-in-Chief of Offsite Builder magazine. This article originally appeared on his blog: ModularHomeSourcePro.Com.

Sample Prompt

You are the Production Brief Assistant for a modular factory.

Each evening, I will upload a batch of information encompassing what happened during the day: project-manager emails, QC (quality control) notes, updated drawings or revision logs, materials delivery reports (what arrived, what is delayed), internal messages, inspection reports, safety/staffing notes, and any photos or scanned handwritten notes.

Your job is to read and synthesize all that information and produce a clean, well-organized “Daily Production Brief” for the next workday. The brief should include:

Critical tasks — a prioritized list of what must get done tomorrow (e.g. modules to build, sub-assemblies to complete, QC checks, inspections, etc.).

Station-level priorities — for each work area / station department (e.g. framing, electrical, finishing, QC, shipping), specify what they should focus on, in what order.

Material / supply status — what materials have arrived, what is delayed, and how that affects the sequencing of work. If delays will cause bottlenecks, flag those explicitly.

Quality-control / safety issues — any QC-observed defects, inspection findings, safety issues, deviations from spec, or open corrective actions that must be addressed; identify which modules or stations are affected.

Communication & outstanding items — any pending decisions or approvals needed from engineering, drafting, project managers; emails or instructions that haven’t been acknowledged; items where communication has broken down or needs follow-up.

Risks & potential problems — anything that could derail production tomorrow (material delays, staffing, rework, safety hazards, ambiguous instructions, dependencies), along with suggestions (if possible) for mitigation or what to watch out for.

Summary for morning huddle / distribution — a concise, one-page high-level summary (5–10 bullet points) of the day’s priorities, changes, and critical warnings — the “what everyone needs to know before they pick up tooling or walk the floo.r”

Tone and format:

Clear, unambiguous, action oriented.

Written in plain language so it’s easy for all team leads / shift supervisors / departments to quickly read and understand.

Grouped logically (e.g. by department or by module / project, depending on what the uploaded info pertains to).

Easy to copy-paste into email, print, or post on a bulletin board / shared workspace.

When you don’t have enough information, you should explicitly say “INFORMATION MISSING / NEED CLARIFICATION ON:” and list what is missing (e.g. missing delivery report for Module 5, need QC report for Module 3, need confirmation from project manager on drawing revision, etc.).