Trips not taken are a guaranteed route to improving margins.

- A dive into the numbers reveals that unnecessary trips to the jobsite add thousands of dollars in cost to a typical home. Most of these costs are hidden.

- By using the author’s Trip Cost Calculator, builders can estimate these hidden costs for the specific homes they build.

- Switching from site framing to offsite-built components can help the builder eliminate up to 80% of these hidden costs.

What if I told you that the hidden cost of wasted trips to building sites in America is, very conservatively, $12.5 billion per year, and that at least 80% of that total – call it an even $10 billion – is laying there, waiting to be picked up, yet hardly anyone is going after it? I have incontestable proof, real data, that this number is real. How do we calculate it? I’ll save that to the end, but I hope even the greatest skeptic will read on.

The first three articles in this series (see links at the end of this article) focused on the evaluation and comparison of on-site versus offsite building methods. The premise is that if we learn to fully measure the true total costs and benefits of each approach, the decision to use more offsite-built components becomes not just easy, but obvious.

Unnecessary Trips

In this final installment, I address one of the most consistently overlooked and undervalued factors of all — the costs and consequences of unnecessary trips to the building site. If you don’t immediately recognize the problem and hear strains of “what’s Wasted Trips got to do with it?” (apologies to Tina Turner), let’s stop and think.

In Part 2, I used the example of a Southeast builder who was able to reduce critical path cycle time by nine full days on a 2300 square foot, two-story home. The builder achieved this result by switching from site-framed floors and walls to prefabricated floor trusses and wall panels, which cut the number of material deliveries needed, sped up the work of framers and mechanical trades, and reduced site waste.

Now let’s add to those savings the number of wasted trips that the use of advanced components eliminated for this build. First, it is important to differentiate between “planned trips” which are on the standard build schedule, and “extra trips” which result from issues that include take-off errors, damage, lumber that’s either stolen or “borrowed” from one site to build on another, etc.

For this house, the use of components saved the lumber company two planned delivery trips. Our use of the TrueNorth Trip Cost Calculator Excel Template (Trip Cost Calculator) with more than 500 lumber dealers has told us that trips cost an average of $450 each, and sometimes more. In addition, the lumber company predicted they would save at least one unplanned “hot shot” run to replace missing or damaged materials, at an average cost of $250 per trip. The total savings, therefore, adds up to $1150 per unit. That’s real money.

Now consider the framing crew. We typically see between four to 12 men on a crew, but let’s be conservative and call it six. It takes them an average of 10 days to frame a house with dimensional lumber. With the new process, however, they can frame the house in a single day. That’s at least 54 trips saved by crew members (six trips per day not taken over nine days).

Now you may say OK, maybe that counts if they are employees, but the framers are pieceworkers so that’s on them. Oh, really? One thing you learn when you completely understand Lean thinking and Lean process, is that “a dollar is a dollar is a dollar,” no matter who officially bears the burden — or who saves it. The builder always pays for those costs somehow.

So how do we value this? You need to factor in vehicle cost as well as time. As you’ll see on our Trip Cost Calculator, it varies by distance driven, with $100 as a good conservative value per worker per day driving to the site. That’s $5400 in buried cost for the crew.

While you cannot immediately deduct saved trip costs for individual crew members from your construction costs, over time it must help with bids compared to other builders. Where it really comes into play is as a key factor in becoming the “Builder of Choice,” — an absolute essential for any builder wanting to hire and keep the best trades and the best crews. In my work with more than 300 builders over the past 36 years, and this is something the best of them have in common.

Labor and Waste

As part of your evaluation of on-site versus offsite construction methods, don’t overlook the positive impact on other trades, especially mechanical contractors. For example, building with floor trusses eliminates most of the time and debris generated by drilling through TJIs or dimension joists to run mechanicals. It also prevents the errors and rework caused by drilling too close to the edges of those TJIs or joists. The value of this time is significant and cannot be ignored. In the case of this particular house, holes for electrical wiring in the stud walls were also pre-drilled at the component plant, saving the electrician even more time.

Another essential calculation to consider is waste reduction. We have found that the basic use of components will save half of a 30-yard dumpster, the most common size we find on jobsites. The more extensive, advanced component applications used on this building site will save an entire 30-yarder. The cost for a single dumpster pull varies by market from $400 to as much of $800. Again, let’s be conservative and call it $500 in direct cost saving.

There’s one more cost issue associated with this waste — the labor devoted to filling up the dumpster. Although the cost of this labor is buried and does not have a cost code, it’s real and is performed by your trades and employees. We estimate five hours of work averaging $50/hour, or $250 per home. You cannot afford to ignore it.

At the end of this article, you will see an invitation to receive the Saved Day, Trip Cost and Onsite vs. Offsite Excel Template Calculators. As you do your evaluation using these tools, you’ll find additional costs builders rarely include, such as supervision. The longer your cycle time the more difficult this becomes. In this case, shaving nine days off of every home frees up a tremendous amount of overhead. Ignore these costs at your own peril.

Trip Cost Calculator

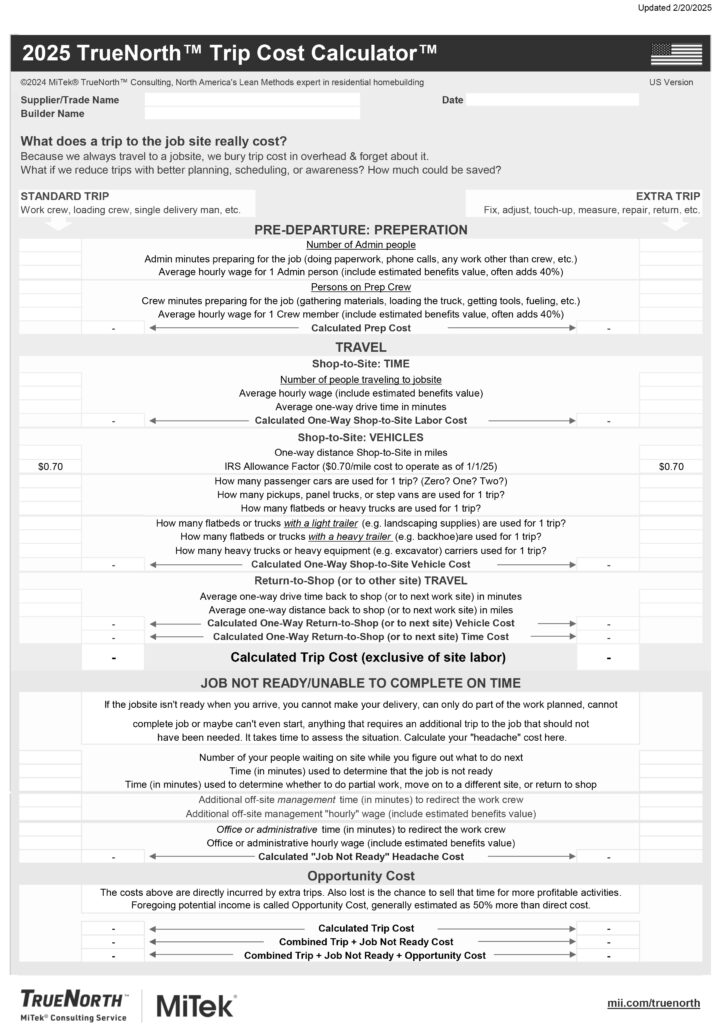

Take a look at the Trip Cost Calculator in the graphic provided. Don’t skim it, study it. The Calculator shown here is an example. The one that we will provide to you has the current IRS cost factors for vehicles in the formulas, but will let you insert your own numbers, following the instructions provided.

Do a couple of calculations yourself, imagining you are any trade or supplier. Then sit down with some trades and run through it. Note there are two columns, one for a standard mobilization for a crew or site delivery, the other for a single person to go on a “fix-it” trip such as an HVAC tech adjusting air flow after move in, or a lumber company making a hot-shot run to replace damaged material.

Notice that you get an initial trip cost when everything goes right, but that there are add-ons for when a supplier cannot deliver or when trades have to work beyond the scheduled time allotment. This approach fully loads the cost, removing the veil from our eyes when evaluating the true, total cost of worksite trips.

When you add it all up, the numbers are going to shock you. You will see trip costs that range from $75 for a quick fix of something to more than $1000 for the mobilization of a foundation crew with equipment. These costs rise significantly when schedule errors and site issues prevent deliveries, in which case crews can’t work because they’re waiting on material deliveries.

Having run this Trip Cost Calculator with nearly 5,000 suppliers and trades during our LeanBuilding workshops, we have compiled solid data. This is where the $12.5 billion loss number comes from.

We’ve calculated a conservative estimate of 50 wasted trips per house at an average of $250 each. (We also have seen builders averaging 100 wasted trips at more than $350 per trip.) That’s $12,500 of costs buried under each new home built in America; costs that can never be recovered. You can, however, prevent these costs in the future by working in collaboration with suppliers and trades. You will find that the more offsite components you use, the better the numbers get.

At something around one million single-family units built in the US per year (there is some confusion about how this number is calculated, such as whether or not it includes rental units, but it’s a fair estimate) we end up with $12.5 billion in waste.

Our experience shows at least 80% of that waste, or about $10,000 per home, can be recovered. That’s real money. Even if you were only able to recover $7500 per unit by reducing wasted trips, is that enough to inspire action? Add these costs to the more than $1100 in hard costs cited above and the other factors outlined in Parts 1, 2, and 3 in this series, such as the value of saved days, and the financial rationale for offsite components approaches “no-brainer” status.

The point of all this? Just comparing labor and material costs of on-site versus offsite construction is not only inadequate, but it also gives you bad data. Without fully comprehensive data, you cannot make the best decisions and that’s no way to run a business.

For a PDF of the entire four-part series including working versions of our Saved Day, Trip Cost and Onsite vs. Offsite Excel Template Calculators, email [email protected]. Please include your company name and preferred email so we can survey you in six months and discover what you have learned.

Links to the first three articles in this series can be found on this page: https://offsitebuilder.com/?s=scott+sedam

Scott Sedam is Principal of TrueNorth Consulting, a MiTek Service. Scott founded TrueNorth 27 years ago following nine years as an executive with a top national builder. The TrueNorth team has worked with more than 300 builders in five countries, and Scott is a well-known writer and speaker at conferences and company events. Please join Scott’s “LeanBuilding Group” on LinkedIn and learn more about TrueNorth services at www.mii.truen.com.