Innovation is important, but according MHBA Hall-of-Fame inductee Vic DePhillips, it must be built on a firm grasp of the basics.

There are not many jobs that modular housing veteran Vic DePhillips has not held in his 50-year career. His titles have spanned a variety of positions — assembler, service man, sales representative, draftsman, plant engineer, sales manager, vice president of sales, vice president of operations, president and CEO. He’s also served as a plant layout and production lines designer for many manufacturers.

At Signature Building Systems of Pennsylvania, DePhillips ran a multi-plant operation that built 1,300 homes per year with more than $55 million in annual sales revenue. He is currently serving as interim president of BiltWise Structures, a modular manufacturer in Greenwood, S.C.

DePhillips has been deeply involved with industry associations, including serving as a member of the executive committee and as Chairman of the Board for NAHB’s Modular Building Systems Council. He is a recent inductee into the Modular Home Builders Associations’ Hall of Fame (2024).

Courtesy of Vic De Phillips

Given his wealth of experience, we decided to ask DePhillips for his thoughts and advice for modular manufacturing startups.

Q: What are some primary lessons your experience has taught you about modular manufacturing?

A: Simply put, this business is not as easy as it looks. I have seen it happen time after time — newcomers to the industry think they have a unique or better way of doing things, but end up floundering. Often, the problem is they don’t understand the basics of costs, procedures and people.

The number one basic is cost: you need to know your costs better than you know yourself. The first thing I look for in a company I’ve been asked to help is how well they control, know and manage their materials and material costs.

Materials are the highest monthly cost in a modular operation, so you must track every bit of material you buy and use. The goal should be to buy smart, not cheap — that is, the lowest price is not always the best choice. Your vendor relationships are important. So are delivery times, product quality, and technical and product support

Carefully monitor the bills of materials for everything you build. Do inventories to monitor the accuracy of your estimating process. Find any discrepancies and fix them.

The number two basic is procedures. You should establish standard operating procedures for every process and action that occurs in your facility. Set up goals and keep logs for engineering, estimating, prospecting and order intake. Constantly monitoring these logs will keep you informed, and will tell you when you need to step up your game.

Monitor your daily production rate versus your production goals. This gives you the ability to recognize obstacles to meeting those goals, and to develop solutions to those obstacles.

Building assemblies should also be standardized. That way, when a problem arises with an assembly, it will be easier to track it back to the source and to take corrective action.

Finally, basic number three, it’s important to remember that people are your greatest asset. You must effectively communicate with them. Workers left in the dark about anything are prone to being ineffective. Cross train your people on your floor the best you can. The more every assembler knows about other parts of the operation, the stronger your operation, as a whole, becomes.

Spend time on the floor and be visible. Engage and get to know the people who make your operation work.

Provide a safe working environment for your people. An injured employee out on worker’s compensation or in rehab means that your workforce is a little less competent than it was before that employee was injured. With a person out, your crew becomes unbalanced, and the team has pick up the slack for that person while they’re out. Recognize and appreciate that.

Q: In the past I’ve heard you say several times “If it’s not broken, break it.” What does that mean?

A: In short, it means you should never stop innovating and improving your process and product. Do not get complacent with your achievements or just think about making money. Don’t assume that because you are making money you are successful. Look for new ideas, processes and procedures to make your company more innovative, because if you don’t, someone else will do it, and they will take your market share.

Q: What don’t they teach the MBA types coming out of business school about creating and running a modular manufacturing startup, but should?

A: While I don’t have an MBA, I assume that school can’t teach you the real-life ways of dealing with the people, problems and diverse situations that occur in the factory every day. I am not certain how a professor who has never been in the position of a president or CEO of a company can possibly teach anything other than the theories of business. They don’t teach common sense, instinct, compassion and dedication.

Q: What fundamentals do you stress in your role as president of any company?

A: You must know how to communicate. You must know your product and your people, and you must make your goals known to them.

You must encourage and nurture a culture of communication among all of your departments. Do this, and you will find yourself pleasantly surprised that your team members want to help other departments with good and constructive ideas that will advance your product and processes.

You also need to know your competition in your space. This helps you specify your product and pricing, while maximizing your profitability.

View your company as a sports team and yourself as the coach. Your aim is to have the best players in every position to assure you a win in the game. Granted, you may not have every person with the skill level you want and need, but if that’s the case, you have to step in and find a way to make them better.

In practical terms, let’s say you have an employee on the floor working in the wall department. He or she comes to work every day on time, takes instruction from the department supervisor and works safely. But for some reason, this person is not keeping pace in the department. Some managers would choose to let that person go, but a right-thinking manager would try to determine the reason this person is not working out and develop a solution or find an alternate position that’s a better fit.

Finally, make your goals known. The supervisors and workers in all of your departments need to understand what is expected of them. You should make your goals for the company known to all, including specifics on how many modules you want to build during the year, what the expected sales amount is, and how you envision the company reaching those goals. You need to help your team understand what it takes to win, and you need to update them on the progress they are making toward that win on a monthly basis.

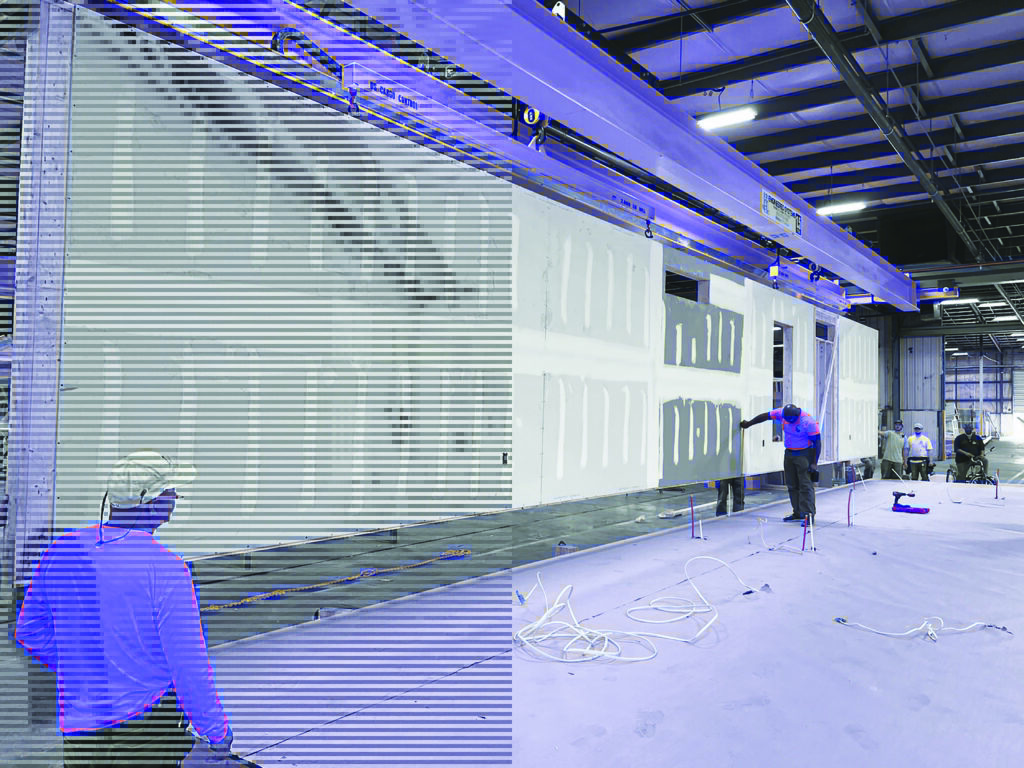

Courtesy of BiltWise Structures

Q: How have the fundamentals, or rules of the road, changed throughout the years?

A: When I first started in this business, it was much simpler than it is today. The changes in codes and regulations, as well as workforce and supply chain challenges have all made this business more complex than it once was.

Years ago, it was easier to get plans approved. We would prepare a plan set, and place it on a table in our engineering department. Then, the third-party inspector (the guy doing the line inspections) would come in to review the plan set and approve it. We could start building it the next day if we wanted to.

Today, there are a hundred pages of calculations. You may need anywhere from 12 to 50 pages of professionally engineered and stamped drawings. The review process can take up to a month, not counting calculation time and stamping. This could extend it even longer depending on the backlog of your third-party inspector.

Also, finding people with any carpentry, electrical and plumbing skills has always been difficult, but COVID only made things worse [because a lot of people left the industry]. Qualified employees are just nowhere to be found.

Q: If you were to pick one rule that people launching a startup should adhere to, what would that be?

A: I would like to believe that every startup has the best intentions for their success. Otherwise, they would not be trying to get into this space. The primary issues I would focus on are know your market, your customers and the cost of doing business. It’s straightforward due diligence.

Q: What should a startup know about the actual building where they will be setting up their operation?

A: Unless you build a new building, which is costly, most startups will be retrofitting an existing building. Its floor area, configuration and ceiling height will have an impact on the layout and flow of your production line. The building will dictate where to stage and place assembly and subassembly stations, cranes and jigs for efficient and safe assembly.

Areas need to be identified where potential slowdowns might happen. For instance, ceiling and roof systems are heavier and are complicated to assemble. Solutions must be designed into your assembly station to keep pace with your desired production rate. This could mean an additional jig, a holding jig and a joist system.

Q: How can a startup ensure that they always deliver a consistent quality product?

A: Do a sample, inline inspection at every station of your line and have standard operating procedures for all installations. Establish who takes responsibility for the work performed and who signs off on the quality control document that stays with the home throughout the production. Typically, the person who performs the work [at each station] initials the document, then the supervisor and the quality control person give the final sign offs. I cannot emphasize this enough: your quality control must be consistent, and you must stay on it at all times. Your production rate is secondary to your quality.

Courtesy of BiltWise Structures

Q: Any other bits of advice you would like to give those who are in the midst of starting up a modular manufacturing facility?

A: Yes. After reading this article, take away at least one idea that you can use in your startup that will help it to succeed. Our industry needs you to be successful. That might sound strange, but it is true. Your potential failure hurts the rest of the companies that are on a positive track. Bad news travels at the speed of light.

Reed Dillon is a content brand specialist, marketing consultant and freelance writer that focusses on offsite and new construction. He is the owner of Creative Brand Content in Moneta, Virginia. Contact: [email protected]