A preview of offerings available to attendees at this year’s BCMC Show

The Building Component Manufacturers Conference and Framer Summit (BCMCShow.com) is celebrating its 40th year. It’s the place where component manufacturers and framers of all types can learn about the latest ideas, trends and products.

This year’s event will be held September 18-22nd at the Indiana Convention Center in Indianapolis, Indiana. It will include a dynamic show floor with machinery demonstrations and educational opportunities.

BCMC will feature 122 exhibitors offering products and services of all types, ranging from factory equipment, to software, to business consultancies. The following is a small sampling of what will be available to attendees, but should provide a taste of what this event has to offer.

Growing a Better Business

4Ward Solutions Group is an industry consultancy that helps offsite manufacturers at all stages — from startups to established companies —with a wide range of business issues. Their expertise includes Lean management, robotics and automation, component design and software development. They help clients become more efficient and profitable with less waste, while focusing on modernization and innovation.

The firm’s in-house team has a combined 250+ years of industry experience, with extensive knowledge in all areas of the building industry, including hands-on experience as owners and operators. 4wardconsult.com

Automated Component Saw

Automation Service Innovation presents the Masik, an automated, computer-controlled, 5-blade component saw. It sets up fast enough for truss-by-truss production, while delivering great performance for batch cuts. It can process dimensional lumber in sizes from 2×3 to 2×12, and in lengths of up to 20 ft.

The saw features 22 state-of-the-art servomotors, four 20 in. blades mounted on 7.5 HP motors and one 32 in. blade mounted on a 10 HP motor. It can read cut files from all major truss design software programs and can run in either automatic or manual mode.

Popular options include a printing system, a catcher display monitor, outfeed track rollers and an inclined scrap conveyor. asinnovation.ca

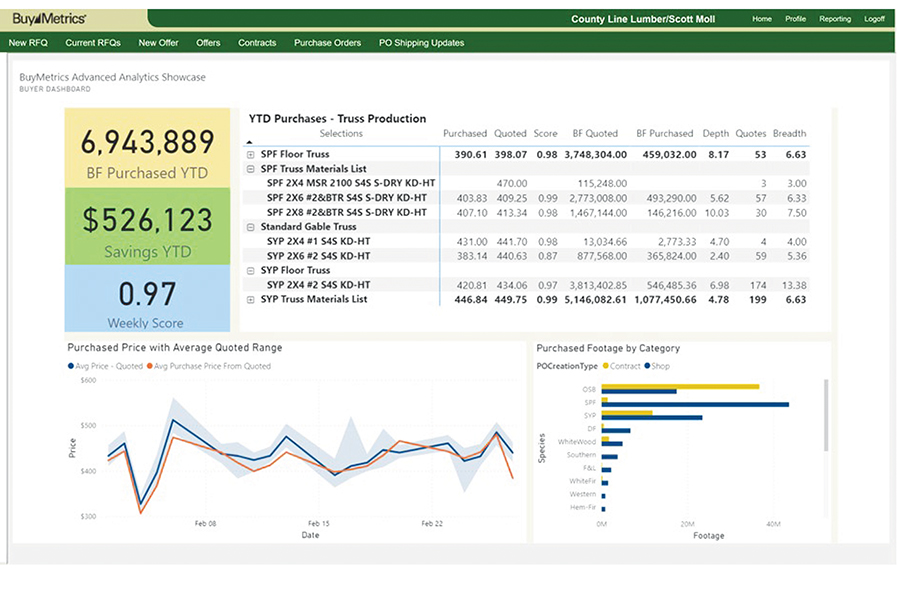

Digital Platform for Lumber Purchasing and Market Analytics

BuyMetrics is not a hub or an exchange. Rather, it’s a private purchasing platform for lumber buyers, with zero transaction fees.

The platform’s technology automates the creation of decision-shaping information, providing buyers with the on-the-fly knowledge they need to make good purchase decisions. This is a crucial benefit; according to the Structural Building Components Association (2019 proforma data), every 1% decrease in lumber cost returns a 10% increase in pretax profit.

BuyMetrics scrutinizes purchase and market data, developing reliable, fact-based insights. It brings transparency to lumber procurement and gives offsite builders the information and insights they need to optimize lumber purchases, plug profit leaks and drive ROI. www.buymetrics.com

3D CAD/CAM Software for Wood Construction

Dietrich’s considers wood to be both the tradition and the future of building. It combines outstanding material properties, durability and ease of processing. And when it’s sustainably harvested from local forests, it also offers the ecological advantages of a renewable resource.

The company was the first to make design software specifically for wood construction. It was founded in 1982, when master carpenter Josef Dietrich developed programs for German carpenters to calculate roof shapes, compound angles and cuts. Today, Dietrich’s is the largest provider of wood construction software in Europe and has grown steadily since entering the North American market in 2002.

Buildings are increasingly required to meet high standards for energy efficiency. The software is used by designers to create energy efficient, net-zero buildings. dietrichs.com/en/

CLT and Wall Panel Fabrication System

The Techno Multiwall XS for Panel Processing from Essetre is a compact, fast and flexible CNC working center for drilling, milling/routing and sawing of wall and/or CLT and Glulam panels.

This machining center will process very big panels: up to 44 ft. long and 10 ft. wide. Traditional wall panels can be 12 in. thick and CLT or Glulam panels up to 5 in. thick.

An optional clamping system stabilizes panels during processing. Other standard features include an 8-position linear tool magazine and CAM software to communicate with end user’s CAD design software. The unit can also be outfitted with a bar code label or inkjet printing heads. www.essetre.com

Truss/Wall CNC Component Processor

Essetre’s Techno Linear Saw is a compact, fast and flexible CNC working center for the drilling, milling/routing and sawing of truss components, wall panel systems, I-Joists and timbers.

The machine’s feeding clamp system stabilizes workpieces during processing. An optional unloading clamp system can be installed to assist processing short workpieces as well as exiting longer EWP I-Joists.

User-friendly CAM software is included to communicate with end user’s CAD design software. Options include an 8-position rotary tool magazine and bar code label or inkjet printing heads for workpiece identification after processing. www.essetre.com

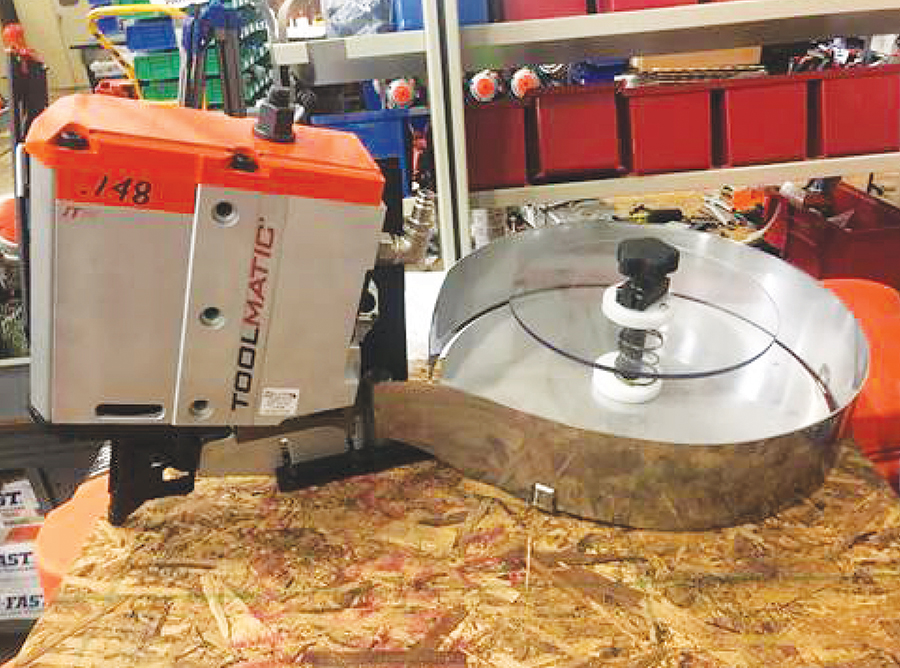

Automated Sheathing Fastener

The purpose of the CW650 Toolmatic Wire Weld Coil Nailer from ITW is the attachment of sheathing to a wall panel. It mounts on the tool bridge of an automated wall assembly table, and its operations are controlled by the table’s software.

The nailer will drive fasteners from 1-3/4 in. to 3-1/2 in. long, and from .099 to .148 diameter. It can handle 700 to 2,500 count coils depending upon the equipment and can drive up to six nails per second, depending upon the length and diameter of the nail.

Although this tool is specifically designed for high automation equipment, the company offers fastening systems for any level of automation. ITW is focused on the offsite construction segment and provides the resources and systems to maximize customer production needs. For more information contact [email protected].

OTR Strapping Solutions

he type of strapping needed to secure an over-the-road load will depend on several factors, including the size of the load, how evenly it’s distributed on the truck, how prone it is to damage and others.

Southern Carlson has a variety of strapping types for every need. At BCMC, it will be showcasing its Challenger line, which includes steel, plastic, polyester, composite and polypropylene strapping.

The company is also a leading distributor of the most recognized, high-quality brands of construction fasteners, tools, packaging, facility supplies and tool repair services. It serves a broad array of markets from more than 150 branches across North America.

southerncarlson.com

Lean Process Improvement

According to Todd Drummond Consulting, a small investment in process improvement has a typical payback time of less than three months.

This consultant helps companies with Lean manufacturing practices, marketing, quality control, production and administration. His industrial, engineering-based process improvements will raise productivity in all departments, not just manufacturing.

Other offerings include the creation of productivity-based inventive programs, equipment and building design recommendations and time standards development for a variety of tasks. todd-drummond.com/