Builders who use them say they offer real advantages, but you need make sure you’re choosing the right product for your needs.

- Closed panels offer speed, quality and cost predictability — but only if builders understand what’s included.

- Good questions, site visits and clear contracts help GCs avoid surprises in scope, installation and scheduling.

- Lenders may resist funding offsite work, so builders must plan financing carefully with their panel partner.

How can builders considering closed-panel construction ensure that they reap the benefits of this construction method rather than running into problems? After briefly summarizing the main reasons to use closed panels, we’ll cover 10 questions to ask before taking the plunge and using them for the first time.

This article is Part 1 of 2. This part will dive into the first three of these questions, while Part 2 will detail the rest. We hope that, together, they can serve as a blueprint to help builders choose the right product for their needs.

We’ll be looking at the closed panel products manufactured by Bensonwood in Walpole, New Hampshire and CertainTeed Offsite Solutions in Malvern, Pennsylvania.

Closed Panel Advantages

Before getting into the questions, let’s look at the reasons why a builder might consider closed panels in the first place. The main three are speed, quality and predictability.

Speed. Closed panels enable builders to quickly get to a water-protected, lockable shell so that MEP work can start in a heated or air-conditioned environment. It takes a lot longer to get to this point with stick-building or open cavity panels.

Ryan Lawler is the Founder and Co-Owner of Fourlite Design-Build, which is headquartered in Weathersfield, Vermont. He has been building with panels from Bensonwood. As of June 2025, his company had completed four panelized homes, has two in mid-construction and has another five scheduled for later in the year. He has been very happy with the speed advantages. “[On an average house], stick framing could take two months to get to the point a panelized house can get to in two weeks,” Lawler says. For a large house, the comparison might be three months versus three weeks.

Quality. Manufacturing in a controlled indoor environment means that weather isn’t an issue. That control helps maintain quality and speed. For instance, Hans Porschitz, Bensonwood’s Operations Officer, says that the ability to pre-install windows is a great advantage during the state’s cold winters. “Adhesives and tapes cure more properly inside the facility. Plus, windows can’t be installed outside on very cold days because the sealant won’t work,” he says.

Dennis Michaud, Managing Director of CertainTeed Offsite Solutions, which manufactures the One Precision Assemblies closed panel system, agrees. He says it’s incredibly difficult to achieve the same level of air and moisture sealing on a jobsite.

In addition, he adds that builders also benefit from the company’s buying power. “In particular, for the windows — which are a very large cost in a home — a builder using our panels is typically getting better quality at a much lower cost.”

Len Carson is building his family’s holiday home on Canadarago Lake in upstate New York using the CertainTeed product. Up to this point, his main experience has been with stick building. “The fact that the panels aren’t exposed to the weather, plus the quality of the craftsmanship, were big factors in my decision” to use closed panels for this legacy home.

Predictability. Porschitz and Lawler both say that with fewer subcontractors involved, there’s less organizational effort and less risk of unforeseen delays. “Having fewer vendors reduces the number of variables, such as getting accurate and on-time deliveries of lumber,” says Lawler. “Those kinds of things add up to make stick-building unpredictable.”

Costs are also more predictable. Lawler says that he typically gets a fixed price on closed panels, while dimensional lumber prices fluctuate with market conditions.

Panels also reduce the number of change orders. “Even if panelized construction looks a tad more expensive out of the gate, for the end product, you’re paying for exactly what you signed up for. There aren’t a lot of surprises,” says Lawler.

Of course, panels from different companies can vary. Here are some questions that will help you make useful comparisons.

1. What’s included?

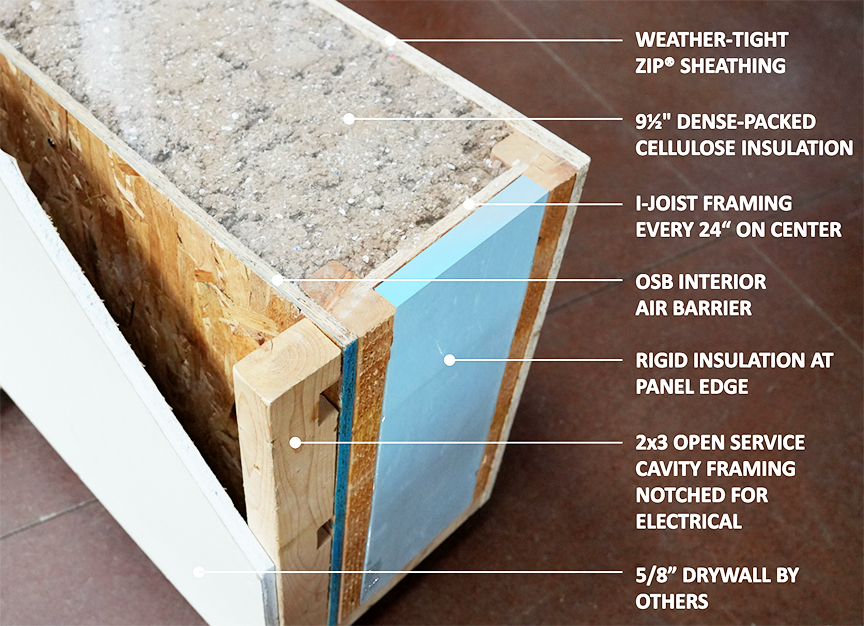

Bensonwood’s panels consist of “a nine and a half inch I-joist framed structure that has framing 24 inches on center and is insulated with cellulose insulation,” explains Porschitz.

Photo courtesy of: Bensonwood

The company also provides open cavity wall panels for garages and other non-conditioned spaces, as well as uninsulated structural panels for inside the building. “These are sometimes just the open panel with no sheathing, and sometimes they’re framing and sheathing,” Porschitz says.

CertainTeed’s closed panels are similar, and include exterior sheathing, 2×6 wall framing, blown insulation, and an air & vapor barrier. Michaud says they’re shipped as part of a total structural package that also includes dimensional lumber, I-joists, or LVLs for other parts of the structure.

Windows and doors. CertainTeed and Bensonwood both pre-install windows and flashing. As for doors, Michaud says that “the jamb is pre-installed, but in some cases the door itself is installed on the jobsite. Some of these are very high value doors, so it’s better to keep them packaged,” and to install them later.

Bensonwood also doesn’t always pre-install exterior doors, although they’re still part of the kit. “There might be a temporary door for use during construction, then the final door is put in later,” Porschitz says. “But we also have solutions where we install the doors in the factory.”

Roofs. Carson notes that one of the competitors he looked at did not include the roof in their kits. “Only their walls were panelized,” he says.Both Bensonwood and CertainTeed make panelized roofs.

According to Porschitz, “Our panelized roofs can be any style [flat, gable, shed, hip, etc.], so the building is insulated and weathertight as soon as they’re installed.” Roof panels are also insulated and sheathed on both sides.

However, Lawler notes that “Bensonwood is very clear that it’s the general contractor’s responsibility to put roofing paper and ice and water shield on the building as kind of a secondary layer of defense which is pretty common even in stick framing.” CertainTeed’s system also requires this layer to be put on as soon as possible after the roof is installed.

Drywall. Neither system comes with drywall installed. Porschitz says that Bensonwood “did experiment with putting gypsum board on the interior of our exterior insulated walls. We thought that would be an added value.” However, they discovered that this wasn’t a benefit for the GC. “Because the interior partitions were still just open framing, the drywaller had to come in to do them anyway.” It turned out to be easier for their customers to have all drywall work done on-site.

CertainTeed takes a similar approach. “One of our principles is that any trade work done in the factory will be entirely completed by CertainTeed,” says Michaud. “That’s why all the windows, and all the insulation are included.” They don’t want to leave part of the work to site trades.

Leaving the interior finishes such as cabinetry, kitchens and bathrooms for the builder to complete is also better for CertainTeed’s customers, Michaud says. “Builders aren’t making their profit on the framing or the insulation of the building. They’re making their profit on beautiful kitchens and bathrooms. So, we leave that to them to execute and benefit from.”

Photo courtesy of: CertainTeed

Siding. Siding isn’t included in Bensonwood’s kits. Porschitz says the reason is largely because of aesthetics. “Suppose the front wall of a house is 50 feet and we manufacture two 25-foot sections. If horizontal siding was factory-installed, you’d have a vertical line down the middle of the wall were the two panels come together, which would require some kind of on-site detailing.” It makes more sense to leave all the siding to do on-site.

MEP Readiness. Neither company includes any MEP in their panels, but they do both include an uninsulated, framed service layer on the inside of the exterior wall panels through which electrical wires and small plumbing lines can be run without disturbing the insulation. Raceways are pre-drilled to reduce on-site work. “When subcontractors come on-site, all they have to do is run the lines. They don’t need to drill holes or notch out framing.”

2. What’s the GC’s scope?

Related to what is and isn’t included in the kit of components is the issue of scope. GCs need to be crystal clear on what work is done in the factory and what will have to be completed on-site.

Lawler grants that there is a “bit of a learning curve for a general contractor working with a panelized company for the first time” and that good communication is key to the success of a project. He says that Bensonwood provides “a very well-documented contract explaining what scopes they’re responsible for, and what scopes either the client or the general contractor is responsible for.”

He recommends that GCs visit jobsites that use any panels they’re considering. Ask about scopes. Also find out if “there’s a punch list of items or tune up work that the general contractor is responsible for.”

Photo courtesy of: Len Carson

3. Will lenders get onboard?

Most panel manufacturers require funds in advance of installation, to pay for the materials and labor needed to make the panels. They don’t want to wait for payment until after the panels are installed.

This can make banks balk. Lawler says, “Some banks won’t release funds for products that are stored offsite. This is because if the project went belly up, the bank’s investment isn’t in a tangible asset.”

When stick-building, a half-finished house is an asset with value that the bank has invested in. In contrast, “The bank may not release funds until the manufactured product is installed on-site, at which point they’re happy because the materials are part of the property that secures their loan,” explains Lawler. “They feel they have control over it. If, say, the GC disappears the next day, someone else could come in and take over the project.”

Porschitz says that Bensonwood has been successful in establishing relationships with some lenders. They’re working to find a middle-of-the-road position where the lender understands the value that the company manufactures offsite and is willing to fund it. However, he admits that it can be tricky. “There needs to be a change in the lending industry to better accommodate offsite fabrication. A small manufacturer like us can’t float millions of dollars. And then, if the project is delayed, we don’t get paid. We’re not a lending institution. We’re a manufacturer.”

This article will continue in Part 2, which will be published in our September issue.

Photo courtesy of: Ryan Lawler

Zena Ryder writes about construction and robotics for businesses, magazines, and websites. Find her at zenafreelancewriter.com.