Asking the right questions, of the right people, in the right way will generate great returns for your company and your customers.

Voice of the Customer, or VOC, can be your best friend, or your worst enemy. If done correctly, it can serve as a strong foundation for high-quality, consistent customer satisfaction and commercial success in your offsite construction business. If done poorly (which is how it’s usually done), it can lead you down a delusional primrose path of guesswork, high costs, delays and risk.

Understanding All of Your Customers’ Needs

In any business, including your factory, understanding the needs of your customers is critical to success. Most offsite construction leaders know who their external customers are (and there are many). But, from my experience, relatively few (if any) make much of an effort to gather VOC information from those customers.

In addition, almost none realize that they also have many internalcustomers whose needs are just as important to the success of the business. And those few who do recognize the existence of internal customers rarely attempt to understand their needs.

Every step in every process is a customer of the steps that precede it. Understanding this helps you to identify your internal customers, and meeting each of their needs contributes to an efficient, high-quality process. For example, the drywall station is a customer of the wall framing station and the drywallers need framing that has been squared, leveled and plumbed.

Likewise, understanding the needs of your external customers — the people who purchase your homes or buildings — makes it possible for you to offer solutions they will happily buy again and again.

The Wrong Questions

How does our industry usually handle VOC? Not very well.

The few offsite manufacturers who make an effort to understand their customers almost always do it wrong. They never ask their internal customers about anything. And they ask their external customers about solutions, something the customers are not at all qualified to comment on. As a result, they predictably get muddy, confusing and ambiguous answers.

Henry Ford is famous for saying “If I had asked people what they wanted, they would have said faster horses.”

Some think the lesson in Ford’s quote is “Don’t ask customers what they want.” Wrong. The point of this truism is that if you really want to use VOC to create breakthrough solutions, what and how you ask matters.

Yes, dumb questions do exist, just like dumb ideas.

If you simply ask customers what they want in a building, they’ll almost always respond like the buggy riders in Ford’s day: with ambiguous, subjective and unhelpful commentary.

“Make it cheaper / higher quality / faster to build / smaller / bigger / more stylish / less boxy / more durable / greener / easier to maintain / smarter / healthier / more comfortable / more desirable…”

Sound familiar? Trying to innovate on this kind of VOC data usually results in either weird, ‘What were they thinking?’ designs or incremental, uninspiring solutions that won’t keep you in business for long, much less help you transform the building industry.

Unfortunately, this is how even the most “customer-driven” companies approach VOC today. They ask, “What do you want?” questions, and predictably get “faster horses” answers. Then they set their architects, engineers and designers to work developing the fastest horse on the market.

After tons of time and cost sunk into engineering and design, they end up frustrated and baffled when customers reject their game-changing, award-winning designed building. Wasn’t that what customers had asked for?

“Garbage In, Garbage Out (GIGO)” is a saying from the software industry and what many agree is a universal law of process quality. It applies to computing, accounting, cooking and every other process, including offsite design and manufacturing.

VOC inputs, in the form of customer needs and opportunities, come from asking questions. But if you ask the wrong questions, of the wrong people, or in the wrong way, you’re going to get garbage VOC inputs and garbage solution outputs — which is bad for your customers, your bottom line and your career.

The Right Questions

The answer to this challenge is in what’s called Jobs-To-Be-Done innovation theory, or JTBD.

The gist of it is that you need to stop asking unstructured, solutions-based questions (e.g., “What would you like in your offsite-manufactured building?”) that elicit subjective, unqualified answers. Instead, you need to emulate great innovators like Ford, Steve Jobs and others who focus on objective innovation inputs.

Yes, you need to talk to customers. A lot. But when you do, ask these two questions first and foremost:

1. What “job” is the customer trying to get done by “hiring” the solution (your offsite manufactured component)?

Except for hoarders, people don’t generally buy stuff purely to have stuff. According to JTBD, people buy products and services, including buildings or components, to help them get something done.

In Ford’s case, this “job” was getting from point A to point B, and the solution could have been horse-drawn buggies, automobiles, airplanes or roller skates. Your customers want homes or buildings that they can sell to buyers, rent to tenants, live in, or use for their businesses.

Focusing on the job, rather than the solution, is what freed Ford’s mind to disrupt the horse and buggy industry with his automobile. It can free your mind to change the world with offsite manufacturing.

2. What metrics will the customer use to evaluate how well a solution will help them get the job done?

Every time your customers experience a solution (offsite manufacturing, in your case), they’re evaluating, consciously or unconsciously, how effectively that solution will help them get their job, or jobs, done.

For example, if I’m a developer trying to accomplish the job of creating an income-producing, multifamily building, it’s important to me to minimize the maintenance cost of the building. This need, and others like it, are how I decide how well a modular factory will help me get this job done — and, therefore, which factory I will hire.

Your customers (usually) aren’t engineers, designers, or architects. They’re not experts in designing or manufacturing building components off-site. You are. What your customers are experts in are the jobs they’re trying to get done and their needs when trying to do those jobs. So, ask them about those things. You’ll get more meaningful, actionable answers.

You’ll know before you spend a dime on design or engineering which needs are unmet and, as a bonus, the answers you get won’t change by the time you launch your new solution, because JTBDs do not change over time. Your odds of market success will skyrocket and your risk of creating irrelevant solutions that don’t resonate with customers will plummet.

The Engineerovation™ Solution

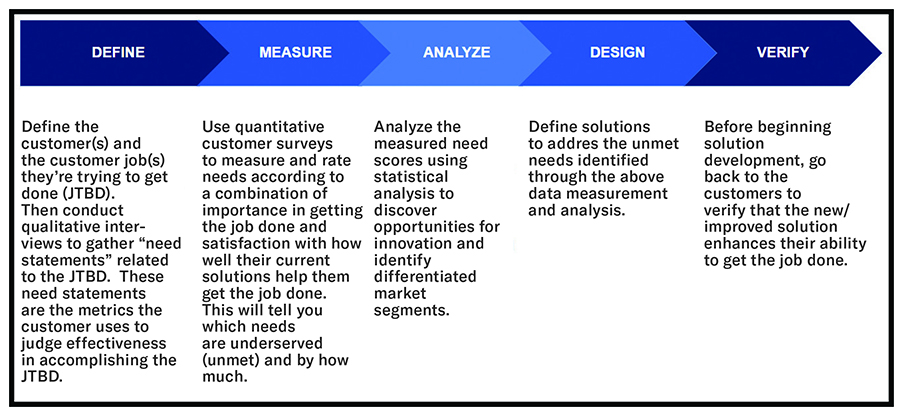

If you’ve read any of my other articles, you’re familiar with the Lean Six Sigma framework for optimizing a process, known as DMAIC. Combining DMAIC with JTBD innovation theory results in what I call Engineerovation™, a powerful VOC framework for a new product, service, or business model development.

Here’s a graphical representation of how it works.

Correctly and consistently gathering VOC data from both your external and internal customers will enable you to improve the solutions you sell and the process by which you create those solutions.

External customer VOC allows you to hone in on what new or improved solutions would make you more indispensable to your external customers. Internal customer VOC gives you the insights you need to refine and optimize your manufacturing process, drive out waste, reduce cost, increase throughput and boost profitability.

Both forms of customer insights are crucial to winning in the offsite construction industry today and tomorrow, particularly as offsite matures and becomes more competitive.

Great VOC research isn’t easy, but the concept is simple: Get the inputs right by asking the right questions, of the right people, in the right way. Making innovation into a science leads to consistently successful solutions.

Daniel Small is a Denver-based management consultant to the building industry. He specializes in Lean Construction and Manufacturing and Six Sigma methodologies. Contact him at [email protected]

[…] As we stand on the brink of what could be the golden era for offsite construction, the path forward is clear. It’s paved with collaboration, open doors and continuous feedback. It’s about embracing Jobs-To-Be-Done to zero in on what really matters, employing a data-driven approach to decision-making and applying Lean principles to streamline our processes. But most importantly, it’s about recognizing that our greatest strength lies in our collective expertise and creativity. (For more on Jobs-to-Be-Done, see my January 2023 article: What Do Your Customers Really Want?) […]