Before hiring a modular transport company, you need to understand the different types of equipment they use.

- The hauling of heavier, wider modules requires precision gear and people who know how to use it.

- Missteps — whether in trailer choice, driver skill, or site conditions — can damage modules in transit or at delivery.

- Owners and GCs who stay involved and choose the right partners reduce risk and rework.

In modular construction, the choice of who will haul units to the site can make or break a project — both literally and financially. Today’s modules tend to be bigger and heavier than in the past, making transport more complex. If you want them to arrive without tears, cracks or other damage, then you need to choose a company with the right combination of trailer, truck and driver for the jobsite and the roads they will be navigating.

Isn’t transport the factory’s job? Not always. Generally, modular factories on the West Coast will make the builder arrange for transport. East Coast factories often provide that service, but they might also depend on the builder to plan out the route and tell them what specialized equipment will be needed to get the module from the road to the building site.

All Trailers Aren’t the Same

Over the past half-decade, many transporters have transitioned to hauling modules on custom-use trailers. These may have as few as three axles, rather than the eight or nine on traditional modular trailers, but because those axles are stronger and have bigger tires, the trailer can handle more weight.

“[With a custom trailer] you can haul the same unit on fewer axles,” says Daryl Snader, Owner of Specialized Transportation in Victoria, Minnesota. Snader’s trailers have three axles and will support a 22,000-pound load.

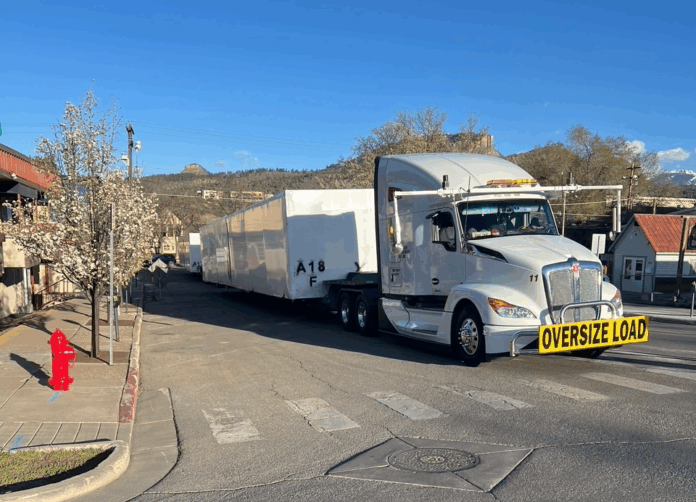

Photo courtesy of Specialized Transportation

High-load capacity sounds great, but the fact is that a custom trailer may or may not be the best choice.

On the pro side, it will be easier to maneuver around tight corners, making it a great choice for delivering to the city or to a subdivision with narrow streets. However, it may not be ideal for some rural sites. Say, for instance, that you need to haul a module up a narrow and windy country road or driveway with culvert ditches along the edge. If a tight turn will put an axle in the air over the ditch, a trailer with eight axles will still provide support.

To avoid trouble, some modular builders hire an escort driver (someone who drives the modular escort car that you see on the highway) to drive the route and make recommendations. In addition to road condition, the driver can identify issues such as sagging power lines that will have to be raised, or overhanging branches that could damage the module and need to be trimmed.

The trailer’s braking system also matters. Some trailers use air brakes, in which compressed air activates the brake chambers at each wheel. Others use electric brakes, which use electricity from the tow vehicle to activate electromagnets in the brake assembly.

To achieve the same stopping power as an air brake system, a trailer with electric brakes will need more axles which, again, will impact the turning radius. However, air brakes will lock up when the truck is detached from the trailer, while electric brakes won’t. If you plan on using tugs or other equipment to move the trailer around the site (more on that below), electric brakes might be a better choice.

Another difference between trailers is how much of the weight is supported instead of hanging off the trailer. “I design my trailers to deliver modules in better condition than the industry standard has been,” says Chad Crosby, Owner of Halo Halo LLC, a Portland, Oregon-based logistics company that specializes in transporting oversized, prefab, modular and mass-timber homes.

Crosby says that his trailers are wider than average. They also have outriggers that allow for even distribution of weight along the module’s rim joist and minimize module flexing. “The modules’ weight is supported from side-to-side, end-to-end and firmly secured to the trailer.”

His trailers also have air ride suspension, which uses airbags (air springs) and a compressor system to cushion the trailer, rather than conventional leaf springs. This greatly reduces road vibration, bouncing and stress on the module.

Truck and Driver

Photo courtesy of Specialized Transportation

Module haulers use different equipment than most other trucking companies. The terms you need to know are Toter, Tug, Translift and Jade. Each machine plays a different role, but together they keep the show running smoothly, on time and on target.

Toter. This is the truck that pulls the modular trailer down the road, but it does so differently than the standard truck. The typical tractor trailer combo uses a coupling system similar to that used for fifth wheels: a kingpin on the trailer drops into a coupler on the truck. A toter pulls the module behind it, like a pickup hauling a travel trailer.

For highway hauling, toter trucks with tandem axles and large bodies make for a smoother ride. On side streets and rural roads, small, single-axle toters have specialized hitches that can move in multiple directions, which makes getting modules to a home site much easier.

Tug. Also called a House Cat, this remote-controlled mini bulldozer can make very sharp turns in very tight areas. It’s also good at moving modules up steep hills.

Translift. Think of a steel I-beam on tracks. The translift can be maneuvered under a modular carrier, then used to lift and move it from side to side. It can help a trailer get around a tight turn and can also be used to adjust the module on-site.

Jade. The Jade, which is also remote-controlled, has wheels and does a job similar to that of the translift, but over a more extreme range of motion. It can really earn its keep with long modules in tight areas.

When it comes to this equipment, drivers have different skill levels. Crosby says that his company sets high standards for drivers. “They must be able to maneuver long loads, keep a clean worksite at the shipper and consignee, and properly support the modules on cribbing amongst other things.”

Hauling modules is also a more physically demanding and technical job than moving standard oversized freight. “Drivers must self-load, back under and lift the modules with the trailers to remove them from the cribbing. They need to secure the modules properly to the trailer, drive safely and carefully drop the mods off on the cribbing.” He says the job requires people who like challenges and who like to stretch themselves.

Photo courtesy of Specialized Transportation

In other words, the job isn’t just about moving the module from Point A to Point B. Someone will ultimately pay if drivers don’t have all the necessary skills. “I look for people who care about the ultimate goal of delivering a module in the best condition possible,” Crosby says.

He adds that drivers also must be willing to say no to the customer when the customer asks for something unreasonable. Such requests could range from dropping the module on a muddy driveway (where the truck could get stuck), to backing down a narrow gravel driveway.

Of course, as our Editor’s Note in this issue details, it’s becoming harder to find qualified drivers. “Hauling oversize is a niche and the people in the industry are aging,” says Snader.

On a more encouraging note, he points out that the general freight market is slow, so some drivers are looking for new opportunities. Some have gotten into transporting modules.

Do You Need a Broker?

Modular deliveries are sometimes coordinated by an entity called a “broker.” This is an intermediary whose job it is to manage the regulatory, logistical and scheduling complexities of delivering modules. Brokers bid the job out to independent truckers, who may or may not have the needed experience to move modular homes.

Snader advises that owners check a broker’s references to ensure that it specializes in modular transport. He says that some brokers claim to know more than they do, and that it’s better to hire the transport company directly. “Going right to us will eliminate the middleman,” he says. “We are the ones doing the transport anyway.”

Photo courtesy of Specialized Transportation

Crosby knows of a brokered modular job where modules were transported over the road and then barged. They arrived at the jobsite with $2 million worth of damage.

He says the industry needs to reset expectations to ensure modules arrive on-site in the best condition possible. For instance, the contractor should assume it’s their responsibility to survey the route, as noted above, to identify potholes, trees, ditches and other obstructions that could cause problems.

“Currently, the manufacturers who hire us are focused only on the cost and not the condition the module is in once off the trailer, as it’s not their responsibility,” says Crosby. “If general contractors and owners were more engaged in the process, the repair and punch list costs would go down.”