Offsite companies that want to thrive in the ADU market need to prioritize thoughtful, user-centric architecture.

- Good design helps compensate for the lack of space and raises the perceived value of your product. It also makes customers more likely to trust in the quality of your builds.

- Customers need design options. ADU manufacturers that ignore that need risk falling behind more agile, customer-focused competitors.

- Winning companies treat design as core strategy, not just as decoration or final polish.

Accessory dwelling units (ADUs) offer some promise of increasing the supply of affordable housing, but “affordable” need not mean low quality or ugly. ADUs are typically sold directly to homeowners — and homeowners will care about the build quality and aesthetics of a permanent structure they’re adding to their property. Any company wanting to succeed in this market needs to take design seriously.

We asked people from two different companies — Irontown in Spanish Fork, Utah (a modular manufacturer) and StudioHome (a panel manufacturer formerly known as Studio Shed) in Louisville, Colorado — about the importance of design when selling ADUs directly to homeowners, and which design factors carry most weight for this market.

Photo courtesy of: StudioHome

Visual Creativity

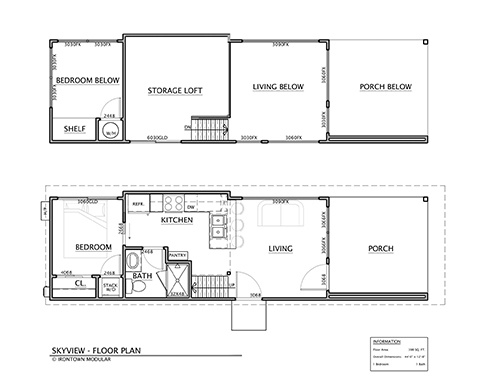

Kam Valgardson is the General Manager at Irontown. He says that while simple boxes “are fine for temporary clinics or jobsites, homeowners typically want more style.” On a large project, it’s possible to “arrange the boxes to get a more interesting appearance. But with a single box, you have to get creative.” He says that customers are willing to forgo a little square footage for a more interesting design. “If you’re not willing to sacrifice any space, then you get a very efficient, very spacious, rectangular box,” Valgardson says.

The company’s designers also create visual interest by “adding some articulation to the walls of the modules, with recessed and protruding areas. This gives some variety to an otherwise straight, flat, boring wall,” says Valgardson. For a single-module ADU, almost all the finishes are done in the factory.

Transport and Setting

Whereas StudioHome makes panelized kits, Irontown manufacturers modular ADUs, which means it has transportation limits. Irontown can ship boxes west to California and Oregon, south into Arizona, north to Idaho and Montana, and east into Colorado and New Mexico.

The company uses its own crew to set smaller projects but outsources larger projects or ones that are too far away. If Irontown isn’t setting the project, they’ll help the homeowner find a contractor to take care of the arrangements for the crane, attaching the module to the foundation and hooking up the utilities.

Because StudioHome manufactures panels, they can ship a lot farther. Their ADUs have been installed coast to coast across the US, as well as in Alaska and Hawaii. They can build to the maximum allowable square footage without having to build a plain box shape. With more than 5000 ADUs installed nationwide, the company has also built a network of contractors and will introduce homeowners to the local contractor they’ve worked with before. Alternatively, homeowners can make arrangements with another contractor or even DIY a project.

Photo courtesy of: Irontown

Floor Plans and Exteriors

StudioHome’s ADUs vary in size from an 80 sq. ft. hobby studio to a 1000 sq. ft. two-bed, two-bath home. Customers can buy just the panels (in which case they get an unfinished shell), or they can purchase a kit that includes HVAC, flooring, cabinetry and fixtures.

Even when all the fixtures and finishes are included, however, drywall and MEP are done in the field. “Wall panels are shipped open stud to provide easy access for traditional field finish. All the interior finishing is done on-site,” says Jeremy Nova, StudioHome’s Co-Founder and Creative Director.

The company has found it important to offer a variety of sizes, according to Nova. “Regulations vary widely across the country for the maximum size ADU you’re allowed to build, and people often have setbacks and other site constraints.” He adds that most people “want to maximize the amount of square footage that they’re allowed to build.”

Customers start with one of StudioHome’s base models and customize it. The customization isn’t merely cosmetic. It includes choices like window type (operable versus floor-to-ceiling fixed glass), roof design, kitchen placement, whether to have one or two bedrooms and bathrooms, the amount of storage versus living space and the type of entry door.

Both Nova and Valgardson say that it’s important to let customers choose from different exterior looks. For example, Irontown offers A-frame, shed and gable roofs. Valgardson also mentions the importance of offering decks. “People want style — either to match their house or contrast with it,” he adds.

A covered deck is a nice way to add living space over the maximum allowable square footage. Nova says that, although it varies by municipality, a covered deck is typically not included in the square footage as long as it has permeable flooring — deck boards instead of a concrete slab, for instance.

Irontown also offers different types of siding, such as lap siding or cedar plank, as well a variety of entry options — the door can go on the side or the front — and flexibility in window placement. This helps homeowners ensure that the ADU will work where they need to place it on their lot.

Photo courtesy of: Irontown

Optimizing Space

ADUs are by nature small spaces. “They’re typically either a studio or a one-bedroom, and there’s not a lot of square footage for a kitchenette, a bathroom, living space, a bedroom and storage,” Nova says. That makes well-designed interiors a must. “We put a lot of time into designing our floor plans,” he adds.

Nova says that StudioHome recently did a substantial redesign of their main product lines, the Summit series and the Aspect model. “We designed them from the inside out, starting with the floorplans and working to the outside. We asked ourselves, what is the most logical layout? For instance, you can’t afford to waste 20 square feet on an entry way. How can we maximize closet space within the constraints of a small bedroom?”

Valgardson notes that the durability of finishes and how much maintenance is required are important to customers. “Irontown tries to put value into our designs, so we use products that are low maintenance and are durable — and which also look nice.” Examples are high-end vinyl flooring that looks like wood but is easier to care for, and fiber cement siding that resists fading and needs painting less often than wood.

Manufacturing ADUs is not for the faint of heart. Valgardson notes that the complexity of these units tends to be underestimated. “An ADU is a small house. That means you have to go through all the steps of building a house and need to include all the elements necessary for a house — but you have to do it all in a smaller space.” Whether a home is an ADU or a full-size house, it still needs a solid structure, a weather-proof exterior, plumbing, HVAC, appliances, and so on. Valgardson adds, “You have to do more ADUs than you would with full-size homes in order to make the same amount of money.”

Photo courtesy of: Irontown

Reaching Customers

Nova sees a trend of more and more customers choosing prefabricated rather than stick-built ADUs, because they’ve learned that manufacturing in a plant “is a more efficient form of construction that generates less waste and is more sustainable in a variety of ways.”

However, sustainability isn’t the differentiating factor that it used to be, according to Valgardson. “Sustainability doesn’t have the same marketing appeal as it did 10 or 15 years ago,” he says. “This is because we’ve already reached such a high standard of sustainability across the whole industry.”

Valgardson says that, to reach customers, “We go to trade shows, and we have a small dealer network we work with.” Of course, Irontown has a website, and they also do email campaigns. He admits that “our social media isn’t yet where I’d like it to be.”

Nova says that most people who are interested in StudioHome’s products come to them online. “We do a lot of digital campaigns that optimize for search intent,” he says. Search intent on the internet refers to the reason behind someone’s search. People may be looking for general information, may be comparing products or services, may be trying to find a specific website, or may be ready to buy. Companies try to make sure their websites are among the ones the search engine deems most relevant to each search. (This is part of what is often called SEO: search engine optimization.)

StudioHome also places ads on Google and is active on social media. “Instagram is our most popular social media channel,” Nova says, because it’s very visual and makes sense for showcasing thoughtful design.

The bottom line is that an ADU is a big investment for most homeowners, and they care greatly about its design. The experts we interviewed emphasize that it’s important for ADU manufacturers to cater to the design needs of their customers. In particular, manufacturers need to give customers enough flexibility — in size, layout and style — so their ADU can suit their budget, their site and their local regulations.

Zena Ryder writes about construction and robotics for businesses, magazines, and websites. Find her at zenafreelancewriter.com.