These promising young companies are bringing new ways of thinking to the offsite industry.

- Their range of innovations reflect a healthy industry that’s actively testing new ideas.

- Materials represented include CLT, steel, concrete and wood.

- The products they make include modules, panels and even bath pods.

What new ideas are today’s entrepreneurs developing in the offsite construction industry? To find out where they’re seeing opportunities, we talked with representatives of four new prefab firms, each of which is using a different material: CLT, concrete, steel framing and wood framing. Their products include panels and volumetric modules.

Despite their different approaches, there’s a common thread with these companies: each is optimistic about the future of prefabrication. Here’s what they had to say:

Modular CLT

Manta North is a European modular manufacturer that’s relatively new to the North American market, expanding here in 2023. Founded in 2018 in Stockholm, Sweden, presently, their primary assembly centers are in Salt Lake City, Utah and Riga, Latvia.

Modules are made with cross-laminated timber (CLT) and the base price of a small, ADU-size finished house (269 to 516 sq. ft.) starts at $149,000 USD. The base price includes a finished interior and exterior, fully equipped with a functional bathroom, kitchen, designer lighting and an efficient HVAC system.

Once delivered to the client’s location, each unit is designed for swift connection to utilities. Manta North takes care of delivery, but local contractors manage additional services such as permitting and installation.

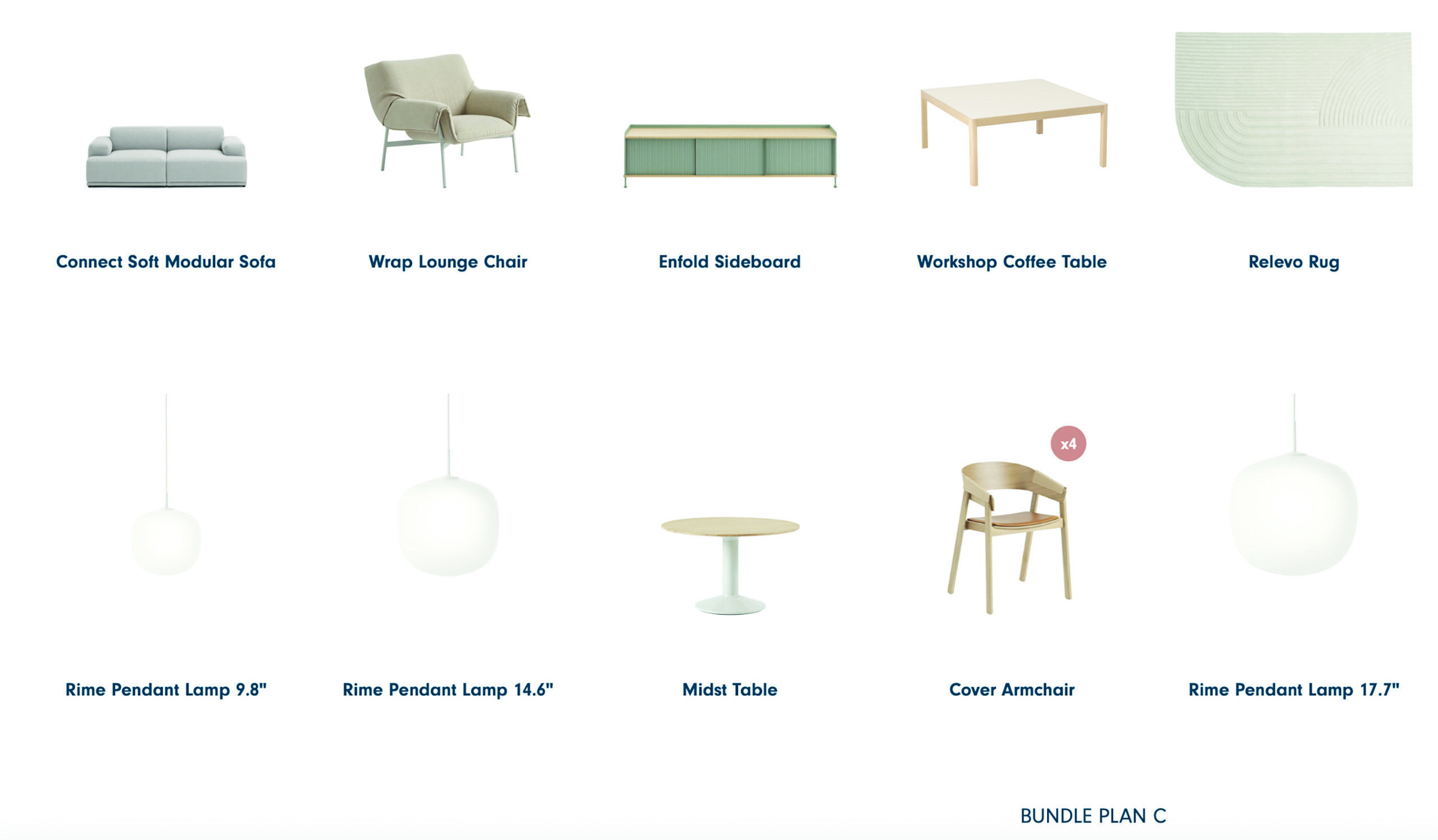

Furniture is also an option. “Our company’s core focus is design, and we’ve partnered with Danish furniture brand, Muuto, which means that US clients can order homes fully furnished with carefully curated pieces,” says Linda Klētniece,Managing Partner at Manta North. “Each furniture set is designed to complement our architectural aesthetic, removing the need for an interior designer. The furniture is delivered at no extra cost.” Along with sofas, chairs and tables, some of the furniture bundles also include rugs, lamps, vases and drinking glasses — all with a distinct Scandinavian vibe.

Last year, Manta North delivered their first North American houses to Big Sky, Montana. They plan to deliver homes across the country. Klētniece says, “Our production model allows for flexibility in manufacturing locations, ensuring efficient delivery and scalability. We’re open to collaborating with prefab housebuilders throughout the US.”

Photo courtesy of Manta North and Muuto

Concrete Panels and Pods

Founded in 2021, Onx Homes is headquartered in Georgetown, Texas but also has US offices in Pompano Beach and Homestead, Florida. A new factory is planned for 2026 in Orlando, Florida. The company has additional locations in Dubai, UAE and Bengaluru, India.

As of spring 2025, the Pompano Beach factory can produce 1,500 homes per year and the Georgetown factory 400.

The company makes a variety of components, including foundations, walls, bathroom pods, slabs and staircases, which Ravi Bhat, Chief Operating Officer, describes as “monolithic 2D and 3D steel reinforced concrete structures.” These components are assembled on-site using the company’s proprietary connectors.

Their steel-reinforced concrete walls are sandwiched with “high-performance, lightweight plant fiber-based insulation,” Bhat says. Onx’s website claims that the walls can withstand hurricane-force winds of 175 mph.

Onx sells their homes directly to consumers. And they’re busy. So far, they have built 700 homes in Florida (in Orlando, Fort Myers and South Florida) and 25 in Georgetown, Texas. Another 2,500 are under development in South and Central Florida, and 1,500 are being built in San Marcos, Austin, and San Antonio, Texas. These communities include both single-family homes and townhouses (each with three to five bedrooms).

In addition to prefabricating wall panels, Onx also manufactures bathroom pods for its homes. The pods “combine high-performance MEP systems with beautifully designed fixtures,” says Bhat.

In February 2025, Onx announced a joint venture with LoanDepot to offer mortgages to its homebuyers. In a press release, Bhat says the goal of this partnership is “to offer homebuyers value and convenience with speed and efficiency… By leveraging LoanDepot’s expertise in mortgage lending, we are creating an exceptional home loan process for our customers.”

Affordable Steel Homes

Based in Gardena, California, ReMo was founded in 2022. In 2023, the company was awarded $3 million by the California Energy Commission. These funds were to develop, test and demonstrate cost-effective, zero-carbon, steel-framed homes that can be deployed promptly.

Affordability is a big part of the company’s strategy. “A typical zero-carbon resilient home costs 20% to 30% more than a traditional home,” says Alex Ferrarese, the company’s Chief of Staff. However, ReMo is aiming for building costs of less than that of a conventional home, as well as operational costs that are 40% lower. She says that the goal is less reliance on government incentives.

To reduce costs, their manufacturing prioritizes efficiency. “A big focus is using Lean design principles — minimal variety of materials, minimal number of parts, low variability and minimal weight — and then eliminating bottlenecks such as wet applications, nailing and welding.” Removing ‘wet applications’ like gluing, painting, drywall, caulking and grouting cuts out drying time. (Interior walls are finished with a fire-proof alternative to drywall, which doesn’t need painting.) The time saved, “when combined with precision manufacturing, enables us to complete installations up to 50 times faster than traditional methods,” Ferrarese says.

They have also opted to standardize their designs. “We produce a three-bedroom, two-bathroom model. We offer some customization for appliances, fixtures and finishes (both interior and exterior), but we don’t offer customization of floor plans or elevations,” Ferrarese says.

Ferrarese explains that standardizing in a large state like California isn’t easy. The company has chosen to focus on regions where 90% of the population lives, which excludes Alpine regions that have high snow loads and areas that fall directly on seismic faults. Nevertheless, that still leaves a lot of variation and ReMo’s website says their homes are built to meet California’s requirements for “16 climate zones, 6 fire zones, and 4 seismic zones.”

For the 2023 Innovative Housing Showcase on the National Mall, they built a prototype unit in 10 days. Since then, they’ve been “refining the design, establishing a component supply chain, further streamlining their manufacturing processes and working with code agencies to get our product approved.” Their standard SupReMo model is three bedrooms, two bathrooms, and 1,200 sq. ft. and is priced at $299,000 (not including delivery and installation).

Quick-Lock Panels

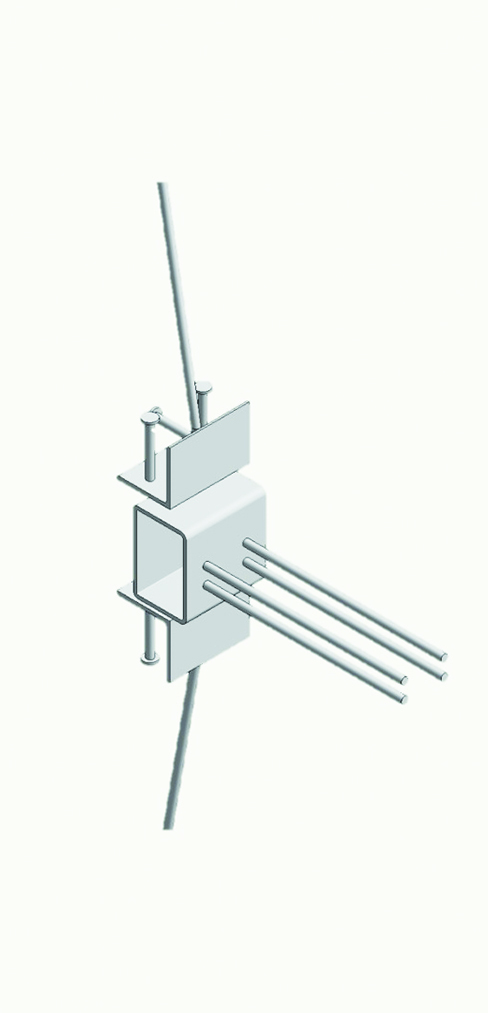

Founded in 2020, MBS is headquartered in St. Louis, Missouri. The company has developed a panelized system that uses a “patented post-tension connection technology,” according to CEO, Mark Turnbull. The system doesn’t use nails, screws, or glue to attach panels; instead, it features what he claims is “a precision locking mechanism that enhances stability and reduces on-site labor.”

Although the company declined to share images, citing IP concerns, they say that the locking system is integrated into the panels and consists of high-strength threaded rods that are tightened on-site. The connection system makes it possible to disassemble the panels, so they can be used for both permanent and temporary applications.

At the time of this writing (spring 2025), MBS is getting ready to build its first manufacturing facility in St. Louis. The company has also partnered with Ranken Technical College in St. Louis. The goal is to create a workforce training pipeline to help students in the trades learn about offsite building technology.

They hope to begin their first pilot projects later this year, “including affordable housing initiatives and disaster relief structures in partnership with municipalities and developers,” Turnbull says.

Zena Ryder writes about construction and robotics for businesses, magazines, and websites. Find her at zenafreelancewriter.com.

Photos were supplied by the manufacturers except where noted.