How do you keep the staging yard from turning into a budget graveyard?

- Factory-to-site delivery is ideal but not guaranteed. Scheduling and entitlement delays make staging yards necessary.

- A good transport company is a valuable partner when it comes to finding a suitable piece of land and negotiating terms.

- Site access, security and cribbing quality are essential to avoiding weather and theft-related damage.

In a perfect world, the challenges, costs, damages and time lapses that can arise from staging yards would not exist. “The goal for modular transportation is to reduce touches,” says Carson Holmquist, CEO and Co-Founder of Stream Modular, a modular transport company based in Scottsdale, Arizona.

What he means is that everyone’s ideal would be for modules to ship directly from the factory to the jobsite, where they’re then quickly moved from the truck to the foundation.

That rarely happens, especially if it’s a large project like a multifamily building. In the real world, factory production, government entitlements and sitework seldom align perfectly. Yes, work on the site can proceed while the modules are being manufactured, but it’s not uncommon for some things to be out of sync.

“Site work or foundation work must be performed before mods can be set, and all the entitlement and permitting must be done before the site work can begin,” Holmquist explains. “There’s a lot of latitude for critical dependencies to derail the timing and sequencing of the events.”

That’s why staging yards — empty lots close to the jobsite where modules can be stored until the set crew is ready to stack — are a necessary additional cost on most projects.

Staging yard expenses can get out of hand. Preventing that from happening requires good management.

Not Just Empty Space

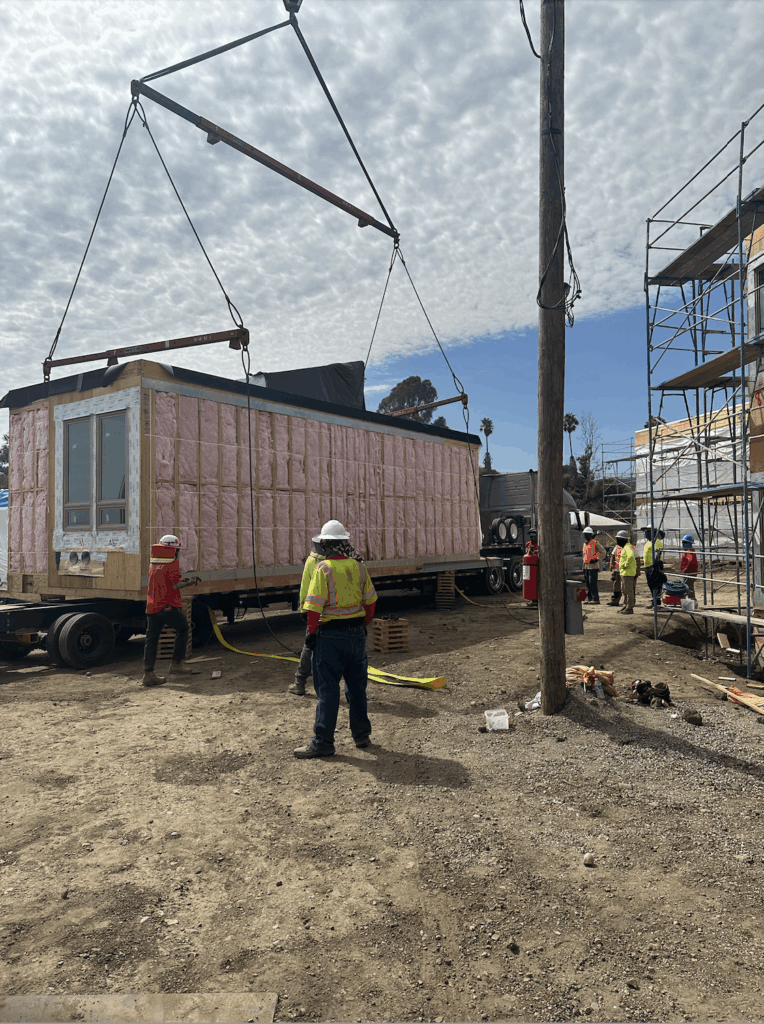

Photo courtesy of courtesy of Specialized Transportation

Finding a staging yard sounds simple enough. You just need an empty lot as close as possible to the jobsite, correct? Unfortunately, it’s not that simple.

First, the staging yard should be big enough to accommodate all the modules. Storing modules in multiple locations adds an unwelcome logistical wrinkle.

It’s also important to inspect the lot in person before committing to it. “On paper it might look like everything will fit, but the real-life experience can be different,” says Daryl Snader, Owner of Specialized Transportation in Victoria, Michigan. He says that one landowner his company worked with only allocated half of the parcel to store modules; the other half was a movie set.

The grounds should be flat and level, with a good substrate. Compacted gravel is ideal. Every modular transportation company has a story about staging yards that were great until they turned into a muddy mess after it rained.

Chad Crosby, Owner of Halo Halo LLC, a shipping and logistics company in Portland, Oregon, shares such an experience. “One time, our team deposited modules at a staging yard that consisted of a grass field [rather than gravel]. It rained, and the field got muddy. The conditions made moving the modules nearly impossible.”

Crosby points to state fairgrounds and parking lots as examples of good staging sites. They tend to have solid, even ground and are clear of debris.

Acquiring a Staging Yard

Finding a piece of land for a staging yard and acquiring it are two different tasks. Projects are occasionally delayed because of the time needed to locate and acquire the rights to the land.

“You have to determine who owns the land,” Holmquist says. If it’s publicly owned, that will complicate the process. “It’s time intensive to get to the right person who can lease land in a city.”

Holmquist and his team offer staging yard management as a service to their clients. After identifying a parcel of land and its owner, the next step is to strike up a conversation.

Inexperienced owners will have a lot of questions. “Many landowners perceive that renting the land will entail risks, so we need to go through their concerns,” Holmquist says.

One big concern is liability, but Holmquist says his company takes care of that. “Our liability insurance covers incidents on the property, and the modules themselves are usually covered under the builders’ risk policy for any damage sustained,” he says. “So, in our experience, the property owners are usually very comfortable with their limited liability exposure.”

Once the owner agrees to move forward, it’s time to negotiate.

Finding and negotiating for the parcel of land is time-consuming. Yet, the process often needs to be done in a tight timeframe. Holmquist and his team frequently manage the staging yard process, so they have been able to develop a list of locations that can be quickly acquired. “We’ve created a database of lots that work well, and which include interest from the owner as well as the leasing rate.”

Photo courtesy of courtesy of Specialized Transportation

It’s a Puzzle

Module storage is a bit like a real-life game of Tetris. If you don’tknow Tetris, it’s a video puzzle game in which players must arrange geometric shapes called “tetrominoes” that constantly fall down onto a playing field. The shapes fall onto the field at increasingly fast speeds. It’s a timed organizational challenge.

How organized does the staging yard need to be? A poorly organized yard leads to more touches and more time, which raises transportation costs. It also leads to other issues. “If modules are dropped off in the wrong order and extra movements are needed, there’s more potential for damage,” Crosby says. To improve the odds of a smooth process, Snader suggests owners discuss the staging yard with the transportation team.

“I like to see the staging yard in advance of when we’ll be dropping off modules,” Snader says. “I can inspect the area, confirm it works, and work out a plan with the set crew.” He makes this first visit well before the date it will be needed, then visits a second time closer to that date (usually four to six weeks ahead of time) to confirm that nothing has changed.

It takes an experienced person who knows what to look for to manage the staging process. One issue that newbies may miss is low telephone wires, which Snader says are common. “Getting everything perfectly lined up is difficult, and it’s especially challenging in cities.”

The easiest way to ensure that modules are properly placed would be for them to be delivered in the reverse order that they will be needed. That is, the last module placed in the staging yard would be the first one needed for the set sequence.

That doesn’t always work. “Lots of times, the manufacturing sequencing is different because of considerations related to efficiency, so they may come out of the factory in an order different from how you’d like to store them,” Holmquist says. The transport company needs to know ahead of time what the factory is shipping, and when, in order to create a storage plan that reduces handling.

A big benefit of good staging yard organization is that it can reduce crane costs, which can range from $5,000 to $10,000 per day depending on location and the type of building. The cranes must be fed as scheduled, and an idle crane will cause costs to escalate.

“You don’t want to have to figure out how you’re going to move the module from the staging yard to the site after the crane is already there,” Snader says.

Other Considerations

There’s also the question of what happens to the modules while they’re in the staging yard. Weatherproofing is crucial. Modules must be well wrapped so they are not subject to the elements. If water gets past the wrap, mold can form.

Cribbing is also essential. This is a temporary support system that elevates and stabilizes the modules. Poor cribbing, i.e., insufficient support, can lead to module damage. The cribbing also needs to be coordinated so that it can be placed and removed quickly and easily. “We prefer stackable and nestable cribbing as it’s easier to handle and transport,” Holmquist says.

The staging yard also needs security. A fence, security guards and/or cameras can be used to keep the yard free of intruders and vandalism. Holmquist has heard of homeless people breaking into staging yards and living in the modules.

A well-organized and secure staging yard near the site where the modules will be set minimizes the extra costs associated with the yard. Investing the time and money to find a good location can save owners from significant excess expense and headaches.