New products are helping manufacturers and builders produce homes that can better withstand nature’s wrath.

As extreme weather events become increasingly common, insurers and homeowners are prioritizing resilient design and construction to help mitigate the impact of natural disasters. This overview highlights a few product solutions that enhance resilience, reduce structural vulnerability in at-risk areas and may increase opportunities for insurance discounts.

Products and strategies like these are being integrated into modular and prefabricated homes in disaster-prone areas. Together, they demonstrate the evolving landscape of resilient building practices aimed at protecting homes and communities from increasingly severe natural hazards.

Resisting Wildfires

In areas at risk for wildfires, mitigation measures and alternative materials can help ensure that homes will be more protected from fire damage.

What products should a builder or manufacturer choose when serving these areas? Some guidance is provided by the State of California, where the Department of Forestry and Fire Protection Office of the State Fire Marshal Building Materials has a list of approved building materials. Inclusion on the list is based on technical data submitted by applicants. The material categories include decking, exterior windows, exterior wall siding and sheathing, exterior doors, under-eave protection, vents, ignition-resistant materials, non-wood roof covering/assemblies and treated lumber.

One company that’s working on getting its products listed (as of July 2025) is Knotwood USA. The company, a subsidiary of Knotwood Australia, manufactures sublimated woodgrain aluminum building products made in the US, and offers non-combustible, fire resilient materials that can potentially help decrease the spread of wildfires.

Knotwood uses a state-of-the-art sublimation technique to infuse woodgrain patterns into VOC- and lead-free powder-coated aluminum. The finished product mimics the appearance and texture of real wood, but resists peeling, cracking and chipping. Snap-together components and concealed fasteners offer the benefits of faster installation.

With over 30 woodgrain finishes and more than 50 solid colors available, Knotwood can be used in various applications including decking, fencing, cladding, battens, soffits and pergolas. Fire-resistant materials make sense for these structures because, if they’re built from combustible materials, they can act as bridges that make it easier for flames to reach the main structure.

Knotwood’s fire-resistant product is Class A Fire Rated and manufactured to meet relevant international fire standards. Additionally, these products are lightweight, insect-proof, 100% recyclable and offer a 15-year finish warranty along with a limited lifetime warranty. (www.Knotwood.com)

Another option for eliminating ignition sources near homes is concrete deck tile. Products such as DekTek Tile offer non-combustible decking options that can help protect homes in wildfire-prone areas by reducing the risk of ember spread.

DekTek Tile is Wildland Urban Interface (WUI)-Compliant, meaning it is designed to withstand extreme fire conditions and is an approved product that complies with Chapter 7A of the California Building Code and Chapter R337 of the California Residential Code.

Photos courtesy of: Knotwood USA

High Wind and Hail

In high wind zones, the type of roof cladding the builder or manufacturer uses makes a big difference. Hurricanes can rip claddings off a roof, and can also cause leaks and other interior damage. One key to preventing roof damage is the use of products that are engineered to withstand heavy rains and high winds.

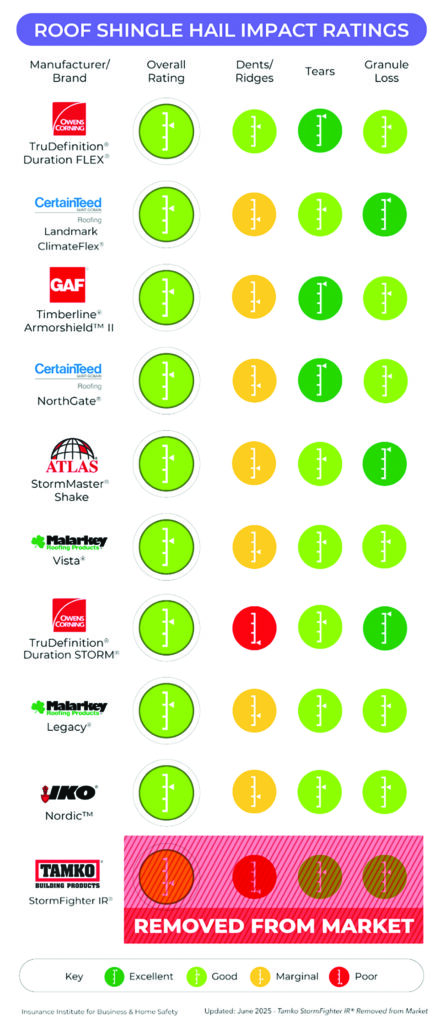

When it comes to hail, the most common types of damage to a roof are dents, cracks or granule loss from shingles. If left unfixed, these problems can result in structural issues and insurance challenges. Again, this raises the question of how to identify the appropriate products. A good source of information is the Insurance Institute for Business & Home Safety (IBHS), which has conducted testing on popular impact-resistant shingles.

High-rated products include Owens Corning’s TrueDefinition Duration FLEX®, which provides the best possible impact rating of UL 2218 Class 4, and may help a homeowner qualify for an insurance discount. These shingles are made with a proprietary blend of SBS polymer modified asphalt that creates a rubber effect and gives the shingles more flexibility and durability under storm conditions. Roof claddings from CertainTeed, Atlas, Malarkey and IKO were also tested and rated.

Of course, another popular roof covering in storm-prone areas like Florida is tile. For those projects, Westlake DaVinci Roofscapes offers a Class 4 impact rated slate roofing tile that’s certified to up to 110 mph with a lifetime limited material warranty. It also carries a Class A fire rating through ASTM E108 testing.

Photo courtesy of: IBHS

Photo courtesy of: Chris Johnson

Flood Mitigation

Homes in flood zones are subject to FEMA’s Substantial Damage Rule, also known as the 50% rule. According to this regulation of the National Flood Insurance Program, if a structure is in a Special Flood Hazard Area (SFHA), and if repairs will exceed 50% of its market value, the entire structure will need to be brought into full compliance with current flood regulations. This often incudes using flood-resistant materials, and installing flood openings.

New homes will likely need to be elevated above the flood line. This usually involves the use of concrete piers, which can be quite expensive, but a new Florida-based product called Durarise claims to cost 20% less while offering protection against Category 8 hurricanes. It’s already being used for new factory-built homes in the state. The Durarise foundation system is engineered to elevate structures to over 14 feet above grade. Currently, the company is working on two notable projects in South Florida. One involves partnering with a large developer based out of Palm Beach who is building 72 elevated fish houses averaging 3,800 sq. ft. each in Cape Coral. The other is an 86-unit upscale manufactured home community in Fort Myers that has broken ground and in which homes will be raised 14 feet to create RV parking below.

The Durarise foundation is rated for 250,000 lbs. and is classified as a permanent foundation. It can support structures of up to 4,000 sq. ft. (including one- or two-story modular units), offers clear span flexibility up to 50 feet and is constructed using high-recycled steel content.

The base model kit starts at $35,000 and has received an engineering stamp for use in the Miami-Dade area. Currently, each foundation package must be engineered to match individual home models, but the company is pursuing broader approvals to streamline the process. In-house engineers can produce custom foundation designs in as little as two days.

The company is also working with insurance providers and mitigation agencies to offer insurance discounts for homeowners who elevate their structures using the Durarise system.

Durarise currently partners with a manufacturing facility that can produce up to 15 kits per week. In addition, the company is breaking ground this year on a state-of-the-art, fully robotic manufacturing facility just outside of Tampa. This new facility will feature precision welding robots and will be capable of producing five kits per day, dramatically increasing production capacity and enabling Durarise to better meet the growing demand for resilient, elevated housing solutions. (www.durarisesystems.com)

Heather Wallace is a freelance writer and industry engagement specialist with over two decades of experience in various areas of the building industry. She has covered topics on construction, technology, workforce development, green building, and sustainable living.