A3s force problem-solving discipline by defining root causes, identifying causes and driving lasting solutions

- In complex offsite factories, the A3 bridges silos, sharpens accountability and prevents recurring mistakes.

- From crane delays to wiring errors, this process cuts waste and can save serious money.

- Root cause analysis helps teams find solutions quickly.

If your offsite factory is like most, you’ve seen binders thicker than cinder blocks and slide decks with enough pages to qualify as bedtime reading. You’ve also seen meetings drag on, decisions stall and problems linger.

Now imagine relief in the form of a crisp, one-page document that forces clarity, sparks action and actually helps solve a problem. Enter the A3 form.

The A3 (named after the Japanese paper size roughly equivalent to 11” x 17”) was born inside Toyota. Developed as part of the Toyota Production System (TPS) —the management approach that became the foundation of Lean — the A3 is the gold standard for structured problem-solving. And in offsite manufacturing, where complexity multiplies between design, production, logistics and field, A3s are a powerful addition to the management toolbox.

What Is an A3 Form, Really?

At its core, an A3 is the structured, one-page story of a problem and its solution. It balances brevity and clarity with visuals and logic. Rather than drowning teams in paragraphs and spreadsheets, it condenses the problem down to its essentials: What’s happening? Why is it happening? What will we do about it? How will we know the solution worked? (More on those steps below.)

The structure of an A3 is closely aligned with the DMAIC framework from Lean Six Sigma: Define, Measure, Analyze, Improve and Control. (For more on DMAIC see my “Modular Process Optimization” series of articles at OffsiteBuilder.com.) But while DMAIC tends to be used to systematically improve a process or product, the A3’s focus is on solving a specific problem, whether it’s excessive crane time or modules that need rework.

The A3’s one-page format keeps the team anchored in facts, analysis and disciplined improvement — without overwhelming readers with technical jargon.

Diagrams and sketches are encouraged on an A3; jargon and fluff are not. It’s less “a report for the record” and more “a story for the team,” with an emphasis on helping them actually solve a problem.

The Secret Sauce

The genius of the A3 lies in the fact that its brevity forces discipline. One page means there’s no hiding behind buzzwords or data dumps. The person or team creating the document must distill the problem down to its essentials. Like a movie trailer, the goal is to communicate the essence of the story without the three-hour runtime.

A3’s can make effective use of visuals. Simple sketches, charts and photos communicate faster and more effectively than walls of text. However, the one-page format means there’s no room for extra slides or tangential discussions — just the facts.

The document also becomes a shared language: from the shop floor to the C-suite, everyone gets the same sheet. And there’s clear ownership: The author of the A3 owns the problem, which sharpens accountability.

In short: PowerPoint decks explain. A3s persuade.

The Value in Offsite

Few industries juggle as many moving parts as offsite construction. A factory must orchestrate design, procurement, trades, logistics and installation — all while under deadline pressure. Design-factory and factory-field disconnects are common.

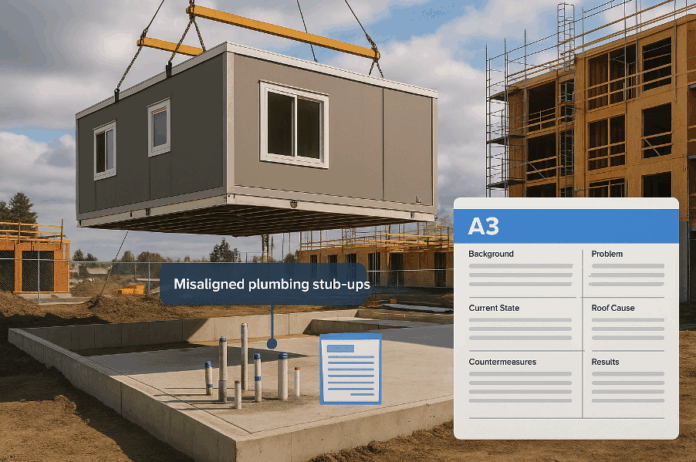

The A3 shines by addressing those disconnects and making the problem visible. When plumbing misaligns in the field, an A3 can document the problem in a structured way, with pictures and facts. It offers cross-functional clarity.

For example:

- If wiring harnesses is taking twice as long as planned, an A3 might reveal the real culprit as missing cable cut lists.

- If cranes are waiting half a day on-site, the A3 might trace that back to shipping sequencing errors.

- If a supplier is sending warped studs to the factory, the A3 will document the problem and drive corrective action.

The point is that A3s bridge silos — design sees what the factory sees, the factory sees what the field sees. A3s create a record of problems and solutions that prevent the same problems from arising again and again.

Anatomy of a Good A3

A solid A3 typically includes five key elements:

The background and current state. What’s happening? The description can include data, photos and context. If plumbing is being mis-installed in modules, document that with photos.

A problem statement. The problem needs to be clearly, yet succinctly defined. For instance, “12% of modules require plumbing rework on-site.”

A root cause analysis. Use tools like the 5 Whys or Fishbone diagram. (For more on how to use these tools, see “Modular Process Optimization, Step 3” in my series referenced above.)

Countermeasures and implementation plan. The document should define who is responsible for fixing the problem, what tools or processes they will use and when solution needs to be completed.

Results and follow-up. You obviously need to know if the solution was effective. The A3 should set a time for follow up and for presenting a plan for how to sustain the solution.

Pro tip: The A3 isn’t about filling out boxes on a form. It’s a working document that’s designed to tell the truth about a problem so that the team can get to work solving it.

An A3 in Action

Picture this: Your factory sends out 100 modules. When they reach the site, 12 of them have plumbing that’s misaligned with the pad stub-ups. Cue panic and cost overruns.

Here’s an example of what might be on an A3 that’s meant to tackle the problem:

- Background: 12% of modules need costly rework.

- Problem: Inconsistent alignment of plumbing with site drawings.

- Current State: Crews need to spend six to eight extra hours per module correcting the problem.

- Root Causes: There has been a variation in the jig fixtures used in the factory. Also, there’s no inspection step before shipment.

- Countermeasures: Standardize the jig fixtures and train operators on proper installation. Add a go/no-go inspection.

- Results: Rework drops to 1%. Installation flow improves. Crane time is reduced (because the crane isn’t sitting on-site waiting for the modules to be fixed). Roughly $75,000 is saved in avoided rework and crane delays. (The results section would be filled in after the results are observed. The A3 then becomes a record of the problem-solving process.)

One page has turned an expensive headache into a factory-wide improvement effort.

Keys to Success

How do you make sure your A3s will have this level of effectiveness? First, start small — do a pilot with one team rather than trying to roll out the process across the factory right away. Spend enough time to complete an effective root cause analysis. Post A3s where crews can see them and contribute solutions. Incorporate them into daily huddles and continuous improvement operations. Review them weekly or monthly to stay engaged without micromanaging. Tie results to the appropriate metrics on quality, cost and delivery.

The goal here isn’t just to get employees filling out paperwork. Ultimately, you want them to embrace A3 thinking. Even if the process isn’t perfect, when used consistently it will build their problem-solving muscles.

Remember to keep it short: One glance should tell everyone the state of a problem and the progress toward fixing it. If your A3 looks like a doctoral thesis, you’ve missed the point.

I can’t emphasize enough that the A3 is way more than a sheet of paper — it’s an investment in sharper thinking and stronger results. Use it correctly and you will be rewarded with less rework, fewer delays, smoother field installs and significant cost savings. Your teams can stop fighting fires and start thinking about permanent solutions. Finally, A3s help grow future leaders by teaching them structured problem-solving.

In offsite manufacturing, stakes are high, schedules are tight and margins are razor thin. Problems arise daily. But sometimes, the answer to a problem is small and focused — a single sheet of paper that forces clarity, tells the story and drives accountability.

So, before your next two-hour problem-solving meeting, try this challenge: fit the issue and the solution on to one A3. If you can’t, you don’t yet understand the problem. If you can, you’ve already won half the battle — and spared everyone another 80-slide presentation.

Daniel Small helps offsite manufacturers increase factory throughput and eliminate waste using Lean strategies. As a specialist in Lean for offsite construction, he optimizes offsite production for scalability and efficiency. Contact him at 719-321-1953 or [email protected], or visit www.DaVinciConsulting.co.