This entrepreneur started a prefab factory in Detroit, Michigan and he says it was a good choice.

- The new 70,000 sq. ft. Light Street factory will ship prefabricated, steel-framed kits to projects in Ohio and Michigan. They want to provide affordable housing at scale.

- To remain profitable, the company has a narrow product focus and a commitment to Lean manufacturing principles.

- CEO John Delia chose Detroit for the new facility in part because of a major reduction in crime, along with a municipal government that wants to attract industry back to the area.

Who will build housing on the vacant lots of the Midwest to meet that region’s growing demand? John Delia, CEO and self-titled “Construction Cowboy” at Light Street Industries, wants to help serve this market by manufacturing prefabricated homes and small apartment buildings, then assembling them on site.

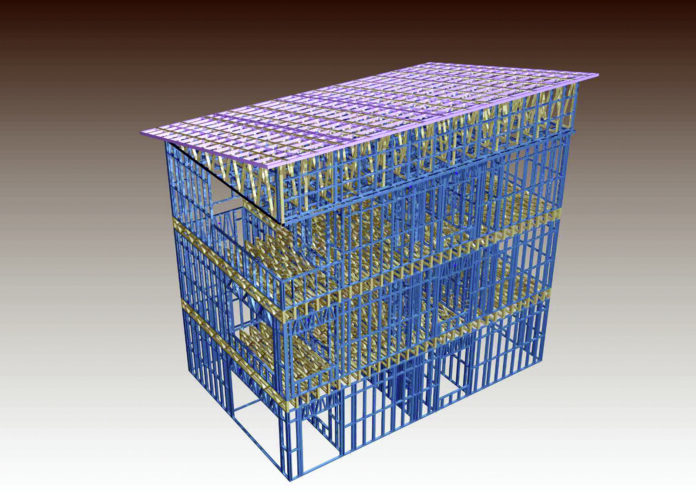

He is currently setting up a new factory in Detroit to manufacture construction kits composed of what he describes as steel-framed “non-volumetric modular elements” — beams, columns, wall panels, interior partitions, floor cassettes and roof trusses.

Light Street Industries also operates a factory in Springfield, Ohio. Delia is a second-generation builder who formerly renovated old homes.

The factory in Detroit is on a 70,000 sq. ft. former industrial site, which was previously vacant and off the grid. It will contain showroom space, as well as the design and engineering operation. It is larger than the Springfield factory.

“The goal of the business is to provide affordable housing at scale, particularly in the Midwest — specifically Ohio and Michigan,” Delia says. “We’re experiencing extreme population growth, with manufacturing jobs coming back to the area.”

As a result, these states are currently also experiencing a housing crisis, Delia says. He wants to build affordable prefab housing to address it. This housing will be sited on infill lots. It will include both single-family homes and apartment buildings of up to four units.

Initially, the construction kits Light Street Industries manufactures will only be the framing package, which will be made from cold-formed steel. Delia’s long-term goal is to be able to ship a kit for almost an entire building in a container, including doors and windows. Light Street Industries does design as well as manufacturing work. The buildings will be designed for specific lot specifications using Building Information Modeling.

Delia has encountered some challenges in marketing his kits. This is partly because it’s unusual to use cold-formed steel in residential construction. Because steel framing only accounts for around 1% of the industry, some local building departments aren’t familiar with this option, even though the code has been established.

Making It Profitable

When it comes to finding land, Delia’s team uses MLS listings (and other search platforms) to identify available lots and properties. They also look for off-market land and reach out to the owners; in fact, most of the properties Light Street Industries buys are off-market.

“We like to be in the path of progress where there is a lack of inventory, but a growing demand,” Delia says.

To obtain approvals, the company talks with municipal government staff and third-party engineers, Delia says. “Before we build, we’re analyzing the zoning codes. Most municipalities have their complete zoning code and regulations online, so we start with the regulations. Once I understand the lot zoning, then I like to go and talk to building officials.”

What is the company doing to make its work profitable? According to Delia, it is keeping its focus and inventory very narrow. “We over-engineer everything to a specific gauge of steel and a specific slit width so we’re not carrying multiple gauges and multiple coils and multiple sizes. I like to call it the Model T approach, but similar to Sears and Roebuck. We’re building out a catalog [of buildings]. We’re not focused on any custom work. We’re focused on repeatable models, and are otherwise staying fairly lean.”

This approach aligns with the well-known Toyota Production System (TPS) as described in the 2004 book The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer, by Jeffrey Liker. The TPS method, on which Lean Manufacturing is based, involves streamlining the manufacturing process, eliminating waste, saving time and reducing inventory.

The steel coils come from MRI Steel Framing, a partner company. John Govis, the Regional Sales Manager there, says Delia has “a lot of big plans.” However, these plans have not yet led to substantial output. “I think the first load of steel he purchased from me was almost a year ago and I think he’s yet to roll it. He thinks that he’s going to be up and running here in the next weeks [as of July 2024]. John’s a very smart individual,” Govis says. He believes that Delia is in a good position to take advantage of potential market growth.

Detroit’s Rebound

Is Detroit a wise location for the new facility? The city had a previous stigma due to blight, abandonment and bankruptcy, but Delia considers it a promising environment for factory investment because of its success at reducing crime. According to a January 3, 2024, press release from the Detroit Police Department, the city “finished 2023 with 252 homicides, the fewest recorded since 1966. The city also saw a 16% reduction in nonfatal shootings and a 34% reduction in carjackings.”

In addition, the Detroit Regional Partnership — an economic development nonprofit, has designated the city as a Smart Manufacturing Hub, and Delia says it’s more business friendly than people might assume. “Right now, we’re talking to multiple [Detroit] agencies in terms of whether we seek a tax abatement or whether we seek specific assistance to finance the factory,” Delia says. “People have been very receptive, helpful and supportive.”

Building community is part of the mission of Light Street Industries. “We started a new professional organization called Home Building Mastery. Homebuilding is a fairly fragmented industry and an insider’s club,” Delia says.

“We’re in the middle of rolling out a full course, but in the near term we host weekly meetups every week where builders, investors and developers can share ideas or ask questions.”

“We want to serve as a peer-to-peer network [that] can create referrals and help people establish in their market,” Delia says. “We can only do so much in our geographical boundary. What I’ve been lucky enough to experience in the industry so far is a very supportive community of peers who will help share information.”

For example, Delia refers larger multifamily projects to his benign competitors.

When asked what advice he would give to entrepreneurs in offsite construction, Delia says he recommends studying the market landscape and understanding the industry, the players and how the industry operates.

Kat Friedrich writes about energy, engineering, physics and technology. She is a graduate of the University of Wisconsin-Madison College of Engineering and is the editor in chief of Solar Today. All images courtesy of John Delia.