The Lean Startup model can support constant improvement in a modular factory while lowering risk. Here’s how to use it.

- Startups test early, learn fast and adapt — an approach that suits modular builders who need to avoid costly errors.

- Lean Startup principles like MVPs reduce risk by validating ideas with real-world feedback before scaling.

- Manufacturers and builders can save time and money by experimenting with small prototypes rather than launching flawed full-scale rollouts.

What could a Silicon Valley startup possibly have in common with a modular construction firm? Quite a lot, it turns out — especially when it comes to building smarter, faster and with less waste.

Startups are known for moving fast, testing ideas early and adapting quickly when things don’t go according to plan. In his book, The Lean Startup, Eric Ries laid out a framework for how entrepreneurs can innovate with fewer resources by learning quickly and failing small. And while his ideas were written for software companies, they’ve got serious power for the world of modular construction.

After all, modular builders are trying to solve some of the same challenges: how to create repeatable products that meet user needs, how to avoid costly mistakes and how to scale effectively. The key is adopting an iterative mindset — building just enough to learn something valuable, then improving based on real-world feedback.

Let’s explore how Lean Startup principles can help modular firms innovate with confidence, cut risk and grow smarter over time.

What’s a Lean Startup Anyway?

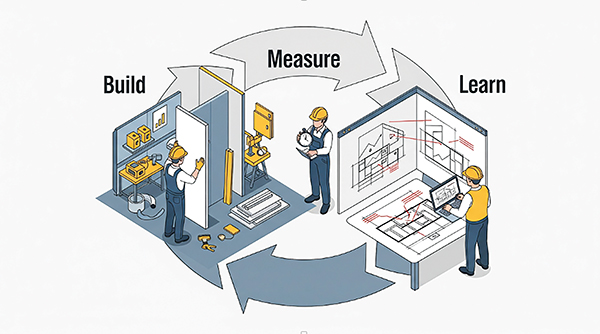

At its core, the Lean Startup approach is about speeding up the learning process. Instead of spending months or years building a product in isolation, startups use a loop called Build → Measure → Learn. They build a basic version (called a Minimum Viable Product, or MVP), test it with real users and use the results to make it better — or pivot to something else.

The MVP isn’t supposed to be perfect. It’s just good enough to learn what’s working and what’s not. The faster you complete that loop, the less time and money you waste on bad assumptions.

Sound familiar? It should. Modular construction is all about minimizing waste, standardizing where possible and improving with every project. But too often, builders wait until it’s too late in the process to test new ideas. That’s where Lean Startup thinking can make a real difference.

MVPs for Modular Builders

In tech, an MVP might be a bare-bones app. In modular, it could be a single prototype module for a new product line, a full-size mockup of a tricky bathroom pod, a scaled test install for a new stair design, or a one-off wall panel built using a new fastener or framing layout.

These MVPs aren’t full-blown product rollouts; they’re small, fast experiments designed to answer specific questions. Does the new module fit cleanly on the foundation? Can the install team hit their takt time? Is there a code issue you didn’t see in the drawings?

One modular firm spent a week prototyping a new panelized wall system. That one prototype revealed three install snags that would’ve caused massive rework down the road. For the cost of a few sheets of OSB and a couple crew-hours, they saved weeks of frustration and tens of thousands of dollars.

Key idea: Minimum Viable Products don’t delay production — they de-risk it.

Build → Measure → Learn (With Buildings)

Here’s what the Lean Startup loop looks like in the offsite world:

Build: Construct a prototype. Run a virtual walkthrough. Set up a test cell.

Measure: Time the process. Record the failure points. Gather crew feedback.

Learn: Adjust the design. Revise your SOP. Update your production line.

Let’s say your team is trying a new type of steel stud framing. Rather than rolling it out across an entire line, you build one framed section, test your assumptions and revise. Maybe you find the new material is too springy and slows down drywall install. Better to learn that now than halfway through a school project with 40 modules.

The faster you run that loop, the faster your systems improve. In modular, where mistakes are multiplied at scale, learning early is everything.

Iteration Across the Lifecycle

Lean Startup thinking doesn’t just apply to product development. It applies across the modular lifecycle.

For instance, the design team tests client preferences with a 3-day design sprint (a quick, focused workshop where a team explores a new product idea, sketches solutions, builds a simple prototype and tests it — all in just three days). They can run early 3D coordination to catch MEP clashes. The design team can make use of a Virtual Reality software program to validate spatial flow.

The factory can test new layouts of workstations or jigs with a single station before scaling them across the factory. They can rapidly test the validity of process changes with a Kaizen event — a short-term workshop aimed at improving a specific process or solving a particular problem. [LD1] (To learn more, see my “Kaizen Event Case Study” in the February 2024 issue.) They can monitor cycle times and defect rates on a per-unit basis.

Field crews can pilot a new module install process on one unit before rolling it out to the entire project. They share punch-list items with the factory and design teams so that factory managers and designers can make improvements that reduce the punch list.

One builder learned over time that stair modules were causing field rework, so they used Lean Startup principles to iterate across three projects: redesigning the module, reworking the install sequence and retraining the field team. By the third install, rework had dropped by 80%.

It’s Disciplined Innovation

Iteration isn’t indecision. Rather, it’s disciplined innovation without the gamble.

Modular builders face a real tension: they want to innovate, but mistakes are expensive. Once something hits the manufacturing line, it’s supposed to be final. And that makes teams hesitant to try new ideas.

Lean Startup principles offer a way out. You don’t have to gamble everything on a new method or material. Instead, you can isolate the risk, test it quickly and measure the results.

Want to try prefab bathroom pods? Do one pod, not a whole project. Thinking about switching adhesives? Run a peel test on one panel. New electrical raceway system? Prototype it on a mock wall and get feedback from your master electrician.

The goal isn’t to get everything right the first time. It’s to make small, fast mistakes that lead to big, smart improvements.

Getting Started

Want to try a Lean Startup approach in your next project? Here are a few low-risk ways to start:

1. Run a 3-day design sprint for your next product line.

2. Build one test wall or module, or try a new install sequence on a small scale before making it standard across the factory. As part of these experiments, measure time, rework and install issues. Get crew feedback.

3. Designate a “Learning Lead.” This is someone on your team who has the responsibility to track experiments and to record what did and didn’t work.

4. After each install, debrief your crews. Ask them what worked and what didn’t work.

Most importantly, create a culture where small failures are celebrated as learning wins. That’s where innovation grows.

Build to Learn

In offsite construction, success isn’t just about getting the job done. It’s about getting smarter every time you build. Lean Startup thinking gives you the tools to do just that.

So the next time you’re rolling out a new product or process, don’t ask, “How do we get this perfect?” Ask, “How can we learn the fastest?”

Because the builders who learn fastest will win the future.

Daniel Small helps offsite manufacturers increase factory throughput and eliminate waste using Lean strategies. As a specialist in Lean for offsite construction, he optimizes offsite production for scalability and efficiency. Contact him at 719-321-1953 or [email protected], or visit www.DaVinciConsulting.co.