The five-step DMAIC cycle is a proven way to remove the friction from any factory process

Chances are, your modular company’s processes could use some improvement. Perhaps your throughput isn’t what it should be. Maybe you’re getting eaten alive by callbacks and warranty work. Your labor costs may be unacceptably high. Or, maybe you just can’t get the information you need, when you need it.

If so, you’re not alone—a lot of other companies have the same challenges. And the obvious questions managers ask once they realize they have a problem are: “How do I go about making it better?” And, “where do I start?”

As an engineer, one of the things I love about Lean Six Sigma—and the reason I launched a business helping companies implement it—is that it offers a methodical, scientific procedure by which any process can be optimized. It’s “a process improvement process,” if you will.

Just like all the processes you follow in your business, from BD, project management, and accounting to manufacturing, delivery, and set & stitch, improving those processes also has a process.

It’s known as the DMAIC (“duh-MAY-ick”) cycle, and it lays out the steps, or phases, for making improvements to any process. They are Define, Measure, Analyze, Improve and Control. Let’s look at each of them, using definitions provided by The Council for Six Sigma Certification’s Black Belt Training Manual (aka “The Manual”).

Phase 1: Define

The Manual defines Define as follows:

During a DMAIC project, the Define phase is concerned with identifying the problem, defining requirements for the project and setting goals for success.

In other words, this first step is where we decide what problem we’re trying to solve. Of course, that’s obvious, but it’s not as easy as you might think. Problems can be tricky to accurately define, and if you get them wrong, then everything you do from there will be compromised.

For example, perhaps you’ve noticed that your callback costs seem inordinately high. Once you’ve determined that you want to tackle this problem, you would identify a goal (say, reducing callback costs by 10%) and determine project requirements such as team members, quality metrics, project sponsor(s) and project duration.

Accurately defining a problem also includes deciding what success looks like, so we’ll know it when we see it.

Phase 2: Measure

To be meaningful, definitions need to be fleshed out with data. According to The Manual:

The Measure phase is when teams use data to validate their assumptions about the process and the problem.

Once we’ve defined the problem and set goals to solve it, we begin gathering data on the current state of the process. In modular factories, this often entails developing and putting in place a data collection system, as the required data usually does not yet exist.

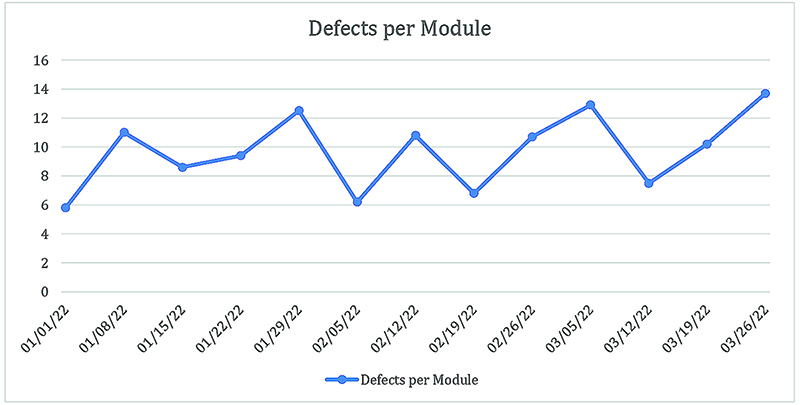

In our callback costs example, the Measure phase might include establishing measurement systems to track defects (per module, as well as by trade/sub-process), failure modes and effects, process variability, and more.

The Measure phase is typically quite detailed and lengthy, as the entire process improvement process relies on quality data inputs.

Once we have gathered enough reliable data, we can validate or revise our assumptions, problem statement, goals and definitions from Phase 1.

Phase 3: Analyze

The Manual defines the Analyze step as follows:

During the Analyze phase, teams develop hypotheses about causal relationships between inputs and outputs, they narrow causation down to the vital few, and use statistical analysis and data to validate the hypotheses and assumptions they’ve made so far.

In this phase, we use statistical analysis to crunch the numbers we’ve collected to figure out the likely causes of the problem or problems. Analysis can be quite involved and is usually performed/led by Lean Six Sigma Black Belts.

Returning to our callback costs example, this phase might include a root cause analysis using tools like a Fishbone cause-and-effect diagram to determine exactly what is causing the defects.

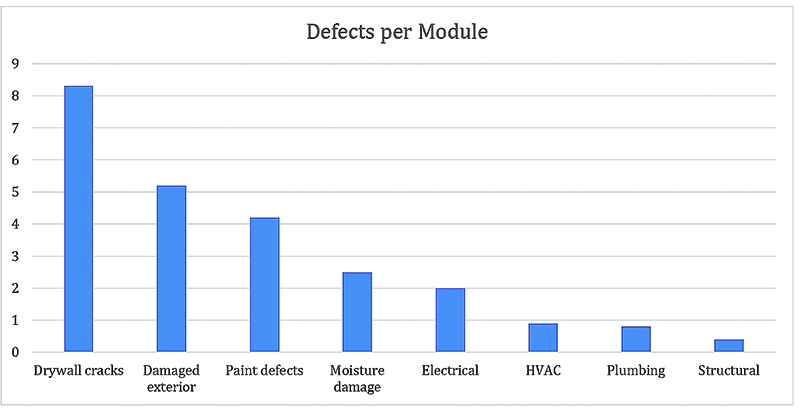

Another useful tool for identifying and prioritizing root causes is a Pareto chart. This tool shows which root causes are responsible for the most failures, enabling efficient use of resources in addressing them.

Phase 4: Improve

In this phase…

Teams start developing the ideas that began in the Analyze phase. They use statistics and real-world observation to test hypotheses and solutions. Teams also work to standardize solutions … and … start measuring results.

Once we know the likely causes of process sub-optimization, we can develop and implement solutions, observe the results and iterate until the problem is solved. Once we’ve confirmed a successful solution, we standardize it and begin measuring it.

For example, we might implement group ideation sessions with the process stakeholders (process owner, workers, customers, etc.) to formulate potential solutions to the most common root causes of module defects and the resulting callbacks. Once a likely solution (e.g. additional structural reinforcement to reduce strain at wall openings) has been selected for implementation based on cost/benefit and attractiveness analysis, a pilot would then be designed and implemented to test the theory.

NOTE: Sometimes, in the process of defining, measuring and analyzing the problem, we may discover that simply improving the existing process will not be sufficient and that instead, a whole new process needs to be developed. Or perhaps the company would like to launch a new solution (product, service, etc.). In those cases, this Improve step becomes a Design step, where the team develops the new solution or process to address the unmet needs identified.

Phase 5: Control

According to the manual…

The control phase is where the project is transitioned to a daily work environment. Controls and standards are established so that improvements can be maintained, … and … the responsibility for those improvements is transitioned to the process owner.

This final step is all about making sure the improvements we’ve worked so hard to identify, develop and implement in steps 1-4 stay implemented and continue to provide their intended benefits, permanently.

For example, once a solution or set of solutions is shown to be effective in improving process results, a control plan should be created to establish parameters, standard operating procedures (SOPs) and metrics to control the new, improved process going forward. The control plan often includes visual management techniques and statistical process control (SPC) charts.

In the case of a new solution or process development rather than improvement, this last step is known as Verify. In this case, it’s used to confirm that the solution or process developed does indeed address the needs of the customer (whether internal or external).

An important part of finishing a DMAIC/DMADV project is team celebration and reflection. This provides immediate feedback and reinforces the practice, enabling continuous improvement to the continuous improvement program.

More to Come

I’ve only scratched the surface here on the DMAIC/DMADV cycle. I’ll delve into each of these steps in further detail in future articles. For now, however, congratulations — you know enough to be dangerous about the process for improving your processes.

You don’t have to put up with sub-optimized processes and the issues they create. DMAIC provides a methodical framework for improving your factory and winning at modular.

For assistance with modular process optimization or DMAIC/DMADV projects, contact Daniel at 719-321-1953 or [email protected].

Daniel Small is a Denver-based management consultant to the building industry. He specializes in Lean Construction and Manufacturing and Six Sigma methodologies. Contact him at [email protected]