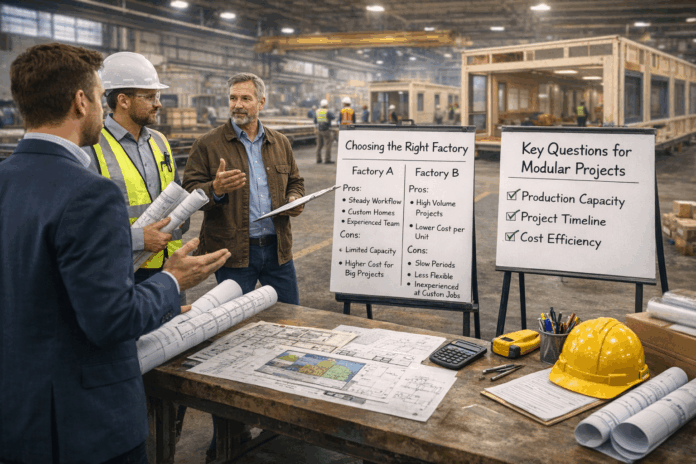

More developers and builders are considering modular construction for their next project. Whether or not they have a good first experience will depend in part on whether they pick the right factory for their project.

One issue builders and developers need to consider is how the factory keeps the production line fed when its core business slows down.

Factories have “sweet spots”— projects at which they excel in efficiency, pricing and quality. In the Northeast, most factories serve an established base of custom builders to whom they offer a range of design options. This business model comes with high fixed overhead — including the cost of supporting a deep bench in the engineering department, as well as other staffing needs.

“You need to understand how the factory keeps its production capacity filled, to ensure that it can build your project in the required timeframe. ”

But what if a developer comes to a custom factory with a 150-unit apartment building? The project must pencil out for the developer, and the factory also has to generate a profit, which it can only realize after covering its overhead. That overhead isn’t going to change just because the factory accepts one cookie-cutter apartment project.

Also, factories that depend on custom builders for regular orders must continue to supply them. Otherwise, those builders will take their business to another factory.

So, the dilemma is this: Does the factory take on a lower-margin project to keep the lines humming, or not? They may have no choice during slow periods, but they can’t afford to clog the line for months and alienate long-term customers. That’s why some factories only accept “small” big projects — making commercial boxes one week and custom residential the next. Even if those commercial projects aren’t profitable, they at least cover overhead and keep everyone working.

By contrast, many factories in the Midwest and the Northwest build hotels or apartments — 150 to 300 modules per project. They have a different problem.

Each project has a projected time to go “online,” but if financing and permitting don’t happen as planned (which is often), the factory must juggle. When a 225 module project gets delayed 45 days, what can it build in the meantime?

A good analogy for the production factory is what I call “marbles in the mason jar.” Imagine that factory as a mason jar. It has lots of large projects to fill it — the marbles. When you put the marbles in the mason jar, is the jar 100% filled? No, there are spaces around them.

To fill the jar to 100%, you need to add sand and shake. If you add enough sand, you will have filled the jar — you will have made sure the factory line has the right mix of work to keep it producing at 100% capacity.

But what types of projects does the sand represent? That’s the trick: Do you know a developer with quadplex or duplex projects that can fill holes in the line? Do you have an investor who has empty lots to place homes on, someone you can build for between big projects?

If you’re a builder/developer, you need to understand how any factory you’re considering handles this issue, to ensure that it can build your specific project within the required timeframe and within your budget. Otherwise, you will be frustrated with the offsite modular construction process because even though you chose a good factory, it wasn’t the right fit for your needs.

To succeed with offsite construction, there are many details that are unknown to the first-time user of the method. It’s not like traditional construction. And first-time success largely depends on selecting the right factory for your project.

If you liked this article, you can follow Ken Semler on LinkedIn, where he offers daily insights and commentary about offsite construction.