Promise Robotics slashes the cost of automation, demonstrating that offsite can be profitable without mega factories.

- The company’s AI-enabled, multi-tasking robots cut costs, save time and simplify offsite building.

- Their system is designed to help builders launch quickly, scale easily and work flexibly with panelized construction.

- By blending automation, design tools and clear pricing, they hope to make advanced offsite building accessible to everyone.

Ramtin Attar is the CEO and Co-Founder of Promise Robotics, headquartered in Edmonton, Alberta, Canada. Six years ago, he and his co-founder set out to address what they saw as the core reasons offsite construction hasn’t scaled: high costs and steep learning curves.

“When my co-founder and I started the company, he was already running one of the largest offsite manufacturers in Canada, with a semi-automated facility that required heavy capital investment,” Attar says. “Our thesis centered on two issues holding back growth in offsite construction: one, automation hasn’t been economically viable, and two, even when money wasn’t the barrier, the learning curve and operational complexity stopped adoption.”

Promise Robotics (Promise), he explains, is “fundamentally a technology company. Our priority doesn’t start with the factory — it starts with lowering the cost of automation and industrialization to make it accessible to the whole industry.”

The Business Model

The company has built artificial intelligence (AI) models that can analyze a home design — whether single-floor, single-family, or multistory, multifamily — and translate that design into robotic instructions. The system uses off-the-shelf robots with Promise-developed tooling to perform complex sequences of tasks that would otherwise require heavy investment in custom machinery and labor.

“This shifts the value away from highly capital-intensive factories to a software-driven system,” Attar says. “Our technology becomes the factory operating system, enabling rapid setup without requiring massive volume to reach profitability.”

Promise Robotics operates its own factories in Edmonton and Calgary, Alberta. The company also partners with builders who want to use its full-stack solution without piecing together machinery, software and IT systems on their own. Attar calls this approach “factory-as-a-service.”

“It’s not exactly a franchise, but the mindset is similar,” he says. “We provide expertise down to job descriptions, performance expectations and what a successful factory balance sheet looks like.”

Builders can bring their orders to one of the two factories that Promise owns, or they can raise capital for a Promise-enabled facility. Either way, the company’s offering is designed to eliminate technical hurdles and reduce risk. “Companies typically risk spending millions on machinery without knowing what software or skills they’ll need, which often leads to failure,” Attar says.

Building Adaptability

“AI has become the new greenwash,” explains Attar. “The term gets thrown around a lot in this space, but just because somebody uses robots doesn’t mean they’re using AI.” He adds that Promise Robotics actually builds AI models, rather than simply using them. “That’s a big difference,” he adds

Traditional automation, Attar explains, often relies on robots pre-programmed to repeat the same task. Automotive factories are an example. Many prefab plants are similar, with gantry systems or bridge machines programmed to nail, cut, or staple along fixed paths. “They’re effective, but they aren’t using AI,” he says.

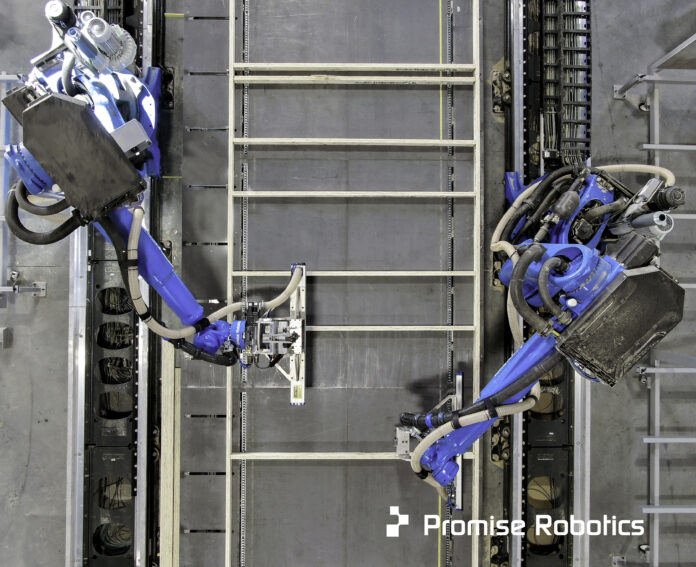

Promise Robotics’ system works differently. Its AI-powered robots have the ability to adapt task by task. “For example, two of our robots can build a simple wall by performing more than 240 tasks. Those tasks vary from wall to wall,” Attar says. “The robots have to know which tools to use, how to collaborate, how to avoid clashing with each other and how to hold pieces in place. These are skills a human carpenter has, but they’re extremely difficult to program.”

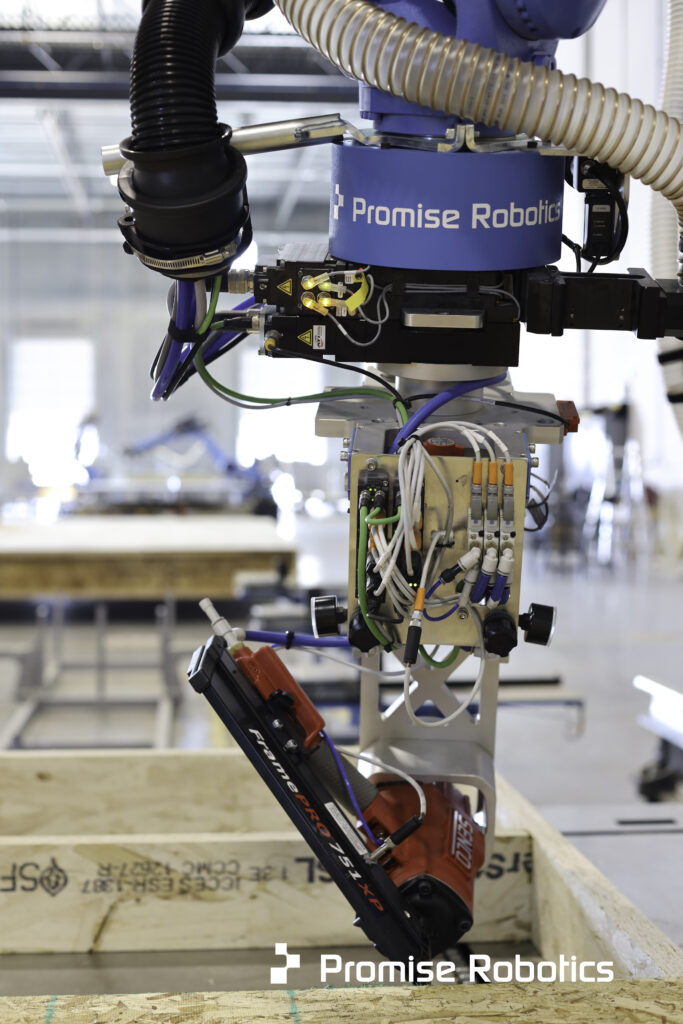

To handle that complexity, the company has developed AI that functions like a “brain” for the robots, supported by 230 sensors in each robotic cell. This allows the machines to recognize missing materials, apply the right amount of force and adjust on the fly.

“Using AI eliminates pre-programming and brings robotic work closer to human problem-solving,” Attar says.

The flexibility means that a wide range of tasks can be performed with just two robots. These tasks include gypsum installation, stapling, notching, cutting, stud placement and framing around windows. Attar calls these machines “the first true industrial carpenters.”

Why They Chose Panels

Promise Robotics focuses on panelization, not full volumetric modular. Attar says the decision came down to market realities.

“Panelization offers maximum flexibility — you don’t need to change your designs to fit a modular system,” he explains. “With modular, you eliminate 80% to 90% of the market because most builders can’t, or won’t, redesign their homes to fit it. With panels, we can work with almost any builder who uses wood.”

Panelization also reduces shipping costs, since factories aren’t “shipping air” in the form of partially finished rooms. “It wasn’t AI that led us to that decision,” Attar says. “It was the market.”

Currently, the company can produce all the components for a typical 1,800 to 2,000 sq. ft. House with a basement in about eight hours, plus another six hours for on-site assembly.

How They Use AI

While other factories may use AI for things like optimizing wood cuts, Attar explains that Promise Robotics’ use of it is far more comprehensive. The company applies AI across multiple aspects of the construction process as follows:

Multi-use robots: Instead of programming separate machines for each task, Promise’s AI enables general-purpose robots to perform hundreds of different operations.

Design: The AI analyzes architectural drawings and translates them into detailed manufacturing instructions, including labor hours and material requirements “down to the nail.”

Workflow sequencing: The system determines how tasks should be divided between robots and manual labor, then sequences operations for maximum efficiency.

Cost transparency: Builders receive precise cost breakdowns, rather than traditional per-squarefoot estimates.

Logistics optimization: While the AI doesn’t yet handle the logistics of site delivery, it does determine the order in which pieces are built, based on the order they’ll be assembled.

Factory management: An enterprise- level platform integrates data from robots, labor and operations, potentially across multiple factories.

Benefits for Factories

Attar maintains that the result of their approach is a set of benefits that make industrialized construction more accessible. “You don’t need to hire engineers or AI experts to run our system. You just need operators, and we provide the training,” Attar says. Additionally, using robots means there’s less need for skilled carpenters and other trades. Robots allow one skilled carpenter to oversee several less-skilled workers.

It’s no surprise that robots enable manufacturers to reduce their reliance on skilled tradespeople, but Promise’s system also requires fewer robots than are usually considered necessary for a fully automated offsite construction facility. Instead of dozens of specialized machines, a small number of multi-purpose robots can handle the work, requiring less space.

Because fewer robots, less labor and less space — including space for offices — is needed, a Promise-enabled facility can be set up for as little as 20% of the cost of a traditional automated factory, often in a rented warehouse.

Of course, the difference in cost varies, depending on what’s compared to the Promise-enabled facility. “To be honest,” Attar says, “the capital expenditure is less important than how many people you need in back offices.” At large production volumes, “operations become very difficult — handling design, pre-production, managing a factory floor, logistics and so on,” Attar says. This complexity typically requires many people working in offices. Along with reducing the factory floor workforce, Promise’s AI reduces the number of office workers needed, too.

Promise’s AI also means that homes can be built with its system even if they weren’t originally designed for factory production. “Standardization helps in manufacturing, but it isn’t required for us to build effectively,” Attar explains.

Factories can also be up and running more quickly. For example, after getting the occupancy permit for their Calgary facility, Promise was producing homes within two weeks. Factories can also scale incrementally, by gradually adding pairs of robots, rather than being built for maximum output upfront.

When it comes to adopting Promise’s system, companies that haven’t yet automated are in a better position than those that have already invested in extensive robotics. “Our experience with existing automated factories is that they treat this just like buying more machinery,” explains Attar, “We try to educate them: the savings are about the entire operation — from pre-production to logistics.”

Replacing one automated machine with a couple of AI-powered robots isn’t the best opportunity, Attar says. “You get the biggest benefits with a larger strategy. Remember, it’s not just about machinery. It’s about software, IT infrastructure, and the operating system that feeds the machines and collects data. You won’t see all the benefits if you just make one small change.”

It’s possible for an automated factory to sell most of the equipment they already have (there’s a market for used robots) and switch to a Promise system that requires far fewer robots. But, of course, that involves disruption to operations. Attar says, “It’s like wanting to change all the plumbing in your house while still living in it. You still want to shower and cook every day, so you’d have to carefully plan and manage that huge disruption.”

Current Clients

At the time of writing, Attar says Promise is working with about half a dozen builders, “some of them among the largest in the market.” As a business, it makes sense for the company to focus on working with large-volume builders, at least initially.

However, he hopes to broaden that market in the future. “When we started Promise, the whole premise was to unlock value for smaller builders,” Attar says. “At the end of the day, many homes are built by smaller builders, so we designed our technology with accessibility in mind to remove those barriers, even for small builders.”

Potential clients are sometimes surprised by what they see when they visit a Promise facility. “A very large builder visited two weeks ago, and said that the technology is much further ahead than they thought possible. They said, ‘I never thought robots could actually build these walls.’”A very large builder visited two weeks ago, and said that the technology is much further ahead than they thought possible.

The Future

For Attar, Promise Robotics represents a new model for industrialized construction — one that shifts value from capital-intensive machinery to adaptable AI-powered systems. By combining flexible multi-use robots, software-driven workflows and a “factory-as-a-service” model, he believes the company can help address the challenges of housing supply while modernizing workforce skills.

“This is a unique moment where crisis meets opportunity,” he says. “We started this company before housing became a headline issue, but we knew the moment would come when AI could position Canada as a global leader in advancing offsite construction.”

Zena Ryder writes about construction and robotics for businesses, magazines, and websites. Find her at zenafreelancewriter.com.