How to launch a DMAIC effort

In my last article, I laid out an overall framework for optimizing any process. Known in Lean Six Sigma circles as DMAIC (Define, Measure, Analyze, Improve, Control), this 5-step method can be used to get more out of any business process.

In my next few articles, I’ll explore each of these five steps in detail. My goal is to help you apply each step and, in turn, improve your modular factory processes. But that’s not all: This same framework can be used to improve any process, including business development, design, preconstruction, accounting, HR, training and more.

Now, let’s look at Step 1 of the DMAIC framework: Define.

The essence of this first step is captured by the most oft-quoted habit from Steven R. Covey’s 7 Habits of Highly Effective People: “Begin with the end in mind.” As with anything, success in improving a process begins with a clear definition of what we’re trying to accomplish, what our objectives are and how we plan to go about doing the work.

The Project Charter

The Define phase is characterized by the development of a Project Charter. This document lays out the road map and ground rules for the process optimization work ahead. It provides the structure and boundaries required for success.

For example, let’s say you discover that your modules are suffering from an unacceptably high rate of drywall cracks and related callbacks and repair costs. You decide to correct the issue. Your first task would be to write a Project Charter that defines the process improvement work.

The five key elements of a Project Charter are:

- Problem Statement & Scope:

What exactly are you trying to accomplish? What is the nature and scope of the problem that needs to be solved? How long is the project anticipated to last? Perhaps as important as defining what is included in the scope of work is clarifying what is not included. It’s very likely the process/sub-process you’ll be working on is intertwined with adjacent and interdependent processes, so delineating the work is critical for clarity. In our drywall cracks example, the problem statement might be, “Excessive drywall cracking in finished modules.” This statement delineates the problem you will focus on (drywall cracking) from other defects or other problems, such as high cycle times for drywall finishing, or low cycle efficiency for drywall hanging.

2. Team Members & Responsibilities:

Process optimization requires focused, closely coordinated work from many people. To facilitate that focus and coordination, you need to clearly establish who will be involved in the project and what their roles and responsibilities will be. In addition, this part of the document should lay out ground rules like meeting frequency, attendance and participation, as well as communication procedures.

In our example, the likely team members might be the Production Manager, the Drywall Department Manager/ Supervisor and the production teams for Drywall Hanging and Drywall Finishing. If necessary, the team can be expanded to include personnel from the Framing crew or even the Setting crew, if it’s determined that those sub-processes are involved in the problem.

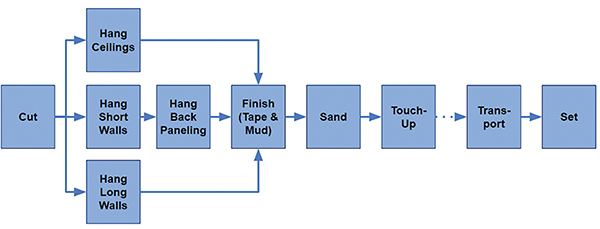

3. Process/Project Diagram or Map:

One of the central tenets of Lean is that you need to visualize the work that needs to be done. Creating a diagram or map of the process to be addressed provides an invaluable

In the drywall cracks example, sources might be upstream processes like framing and cutting. Inputs would be materials like drywall, screws, mud, tape, labor and tools. The output would be a smooth interior enclosure surface. The internal customers would be the painters, trim crews, etc. External customers would include the transport, setting and stitching crews, the builder/GC, maintenance crews, etc. And finally, the traditional external customers: the developer and the building occupants.

4. Customer Information:

You need to determine the sources, outputs and customers (internal and external) for the overall process and its major steps. In addition to your external, traditional customers (developer, builder, municipality, etc.), you have internal customers for various steps and sub-processes. Essentially, the owner of every step in the process is a customer of the previous step.

5. Voice of Customer/ Quality Metrics:

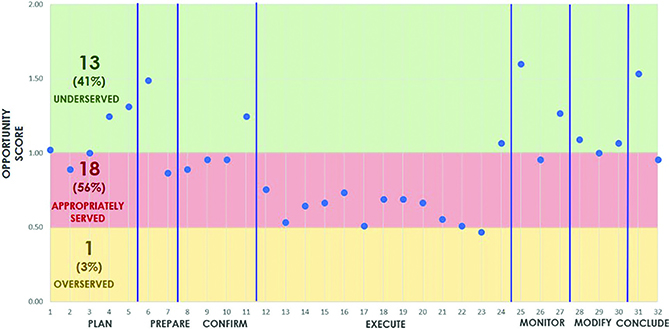

This is where we define success. The goal of an effective process is to efficiently and cost-effectively provide customers with the highest possible quality of outcomes/ solutions. In order to achieve that, you must understand and quantify your customers’ quality metrics and unmet needs.

As a solution provider, one of your most important jobs is to become an expert in the jobs your customers are “hiring” you to help them accomplish (e.g., create cash flow via a multi-family building). Then you can provide a solution that helps them to do that better than any other solution.

Above is an example of a detailed quantitative customer needs analysis, showing the overserved, appropriately served, and underserved customer needs. This type of analysis uses data to determine which needs should be addressed first to add value for the customer, whether external or internal.

The Define phase is critical to success in process optimization and should not be skipped or taken lightly. Each part of the Project Charter requires careful consideration, open communication and research. The work put in here will pay off as you dive into the “meat” of the project.

Once the Project Charter is complete, confirmed and approved, you’re ready to move on to the next phase, Measure, which will be the subject of my next article. Stay tuned!

For assistance with modular process optimization or DMAIC/DMADV projects, contact Daniel at 719-321-1953 or [email protected].

Daniel Small is a Denver-based management consultant to the building industry. He specializes in Lean Construction and Manufacturing and Six Sigma methodologies. Contact him at [email protected]